Leaderboard

Popular Content

Showing content with the highest reputation since 12/18/2013 in Articles

-

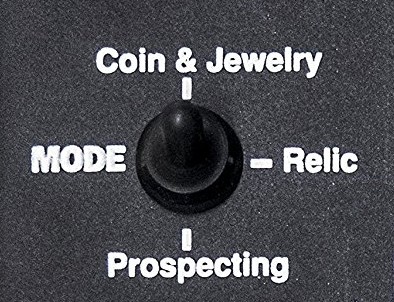

This is my latest "Nugget Detector Guide", now published for over twenty years, updated January 2024 with some of the latest model information. Each model has a short description, followed by a very PERSONAL OPINION. Copyright 2002-2024 Herschbach Enterprises - Please do not reuse or repost without my express permission. This is offered as a simple guide for those wanting a comparison of the various nugget detectors available new with warranty, along with some kind of real opinion about them. That's all it is, folks, so take it or leave it for what it is worth. It's just that listing specs is of little help to people, and so I take my best stab at providing some guidance for those newer to detecting. These are only my opinions based on my experience with various detectors over the years. While I do have a lot of experience, I must throw in the caveat that I have not used all detectors under all conditions. What may be considered a good detector at one location may not be so good at another location due to differences in ground mineralization and the gold itself. Detector performance is site specific and so your mileage may vary. Never forget that when reading comparisons on the internet. Although many detectors sold today can potentially find gold nuggets, I've chosen to only list current models from major manufacturers that are sold and marketed primarily as prospecting detectors or that at least have a specific prospecting mode. I no longer list general purpose VLF detectors running under 18 kHz because they are too common and that being the case they offer nothing special to the potential gold prospector. If you are interested in other general purpose detectors that might make good prospecting machine but are not listed here, look at my more comprehensive reviews list. Many discontinued prospecting detectors are also listed there. Various popular VLF gold nugget prospecting metal detectors Please, if you own one of these detectors, and I call it like I see it, don't take offense. Any nugget detector made will find gold in capable hands, and the owner is far more important than the detector model. I'll put a good operator with almost any detector on this list up against a novice with whatever is deemed "best" and bet on the experienced operator every time. The person using the detector finds the gold. The detector is actually one of the less important factors in nugget detecting success or failure. A quick note to those who know nothing about these machines. These are metal detectors. There is no such thing as a "gold only" detector. These detectors will also find lead, copper, aluminum, and other metals. These units are best used to look for relatively larger pieces of gold at relatively shallow depths. Concentrations of gold dust are not detectable. Some of these units can hit gold that weighs as little as a grain (480 grains per ounce) or less but only at an inch or two. Only the larger nuggets can be found at depths exceeding a foot. Only world class nuggets weighing many ounces can be detected at over two feet. The vast majority of nuggets found are found at inches, not feet. About Long Range Locators (LRLs) WARNING ON COUNTERFEIT DETECTORS - The market for nugget detectors far outsells coin and relic detectors worldwide, with huge sales in third world countries. This has made many of the models below very popular with counterfeiters. Here are some Fisher and Minelab examples. If you shop these models there are two simple rules. First, you are safe if you stick with approved dealers. Second, if the price seems too good to be true, beware! All legitimate dealers have a limit on how low they can advertise, the Minimum Advertised Price (MAP). Review prices at the approved dealer list, and if you find the detector advertised as new at a significantly lower price by somebody not on the list, the odds are very high you are looking at a counterfeit detector. Legitimate dealers are prohibited from advertising at those kind of prices, and a price too good to be true is your number one warning you are about to be ripped off. The detectors are listed in order based on the lowest price normally advertised on the internet as of the date below. Steve's Guide to Gold Nugget Detectors - Updated January 2024 Before I start, a quick note about recent events in the metal detector industry. A few years ago we lost a major manufacturer in the form of Tesoro. That lead to the Tesoro Lobo SuperTRAQ being dropped from this list. 2020 saw one of the true industry stalwarts fall by the wayside. White's Electronics was acquired by Garrett in October of that year. I am therefore dropping the White's nugget detectors from this list as no longer available new with warranty. For now, see my detailed reviews for information on White's models. Bounty Hunter Time Ranger Pro / Fisher F19 ($399, 19 kHz) - This detector is a later, more advanced version of the Fisher Gold Bug Pro (see below), with added features. There is an excellent threshold based all metal mode plus a dual tone discrimination mode. The F19 has both ground grab and manual ground balance, plus adjustable tone break, just like the Gold Bug Pro. Extra features are added to enhance the coin, relic, and jewelry capability, such as notch discrimination with adjustable notch width, volume control, separate ferrous tone volume, and a LCD meter backlight. These extra features may even find use while gold prospecting. The Fisher F19, and the Bounty Hunter Time Ranger Pro, can use any Gold Bug compatible coils plus those made for the Teknetics G2 series, providing for a huge number of possible accessory coils. This detector can be had with several stock coil options, including a 7" x 11" DD coil, or 5" x 10" DD coil. Weight including a single 9V battery is 2.6 lbs. Steve's Opinion - If you can afford it, look at other options below. If you want the lowest price detector worth even looking at for nugget detecting, you can look no farther than here at $399 (or less). First Texas, the manufacturer of Bounty Hunter, Fisher, and Teknetics metal detectors, sells quite a few identical or near identical metal detectors under different brand names and model names. Due to oddities in their marketing scheme, some more powerful models are often available at lower prices than other less capable models. Currently the 19 kHz Gold Bug name carries a premium price, while other identical or more capable models, sold under other names, can often be had for less money. That is currently the case with the 19 kHz Fisher F19 models, and the identical Bounty Hunter Time Ranger Pro model. The bottom line is this. If you can find a BHTRP/Fisher F19 with 5" x 10" elliptical coil for under $500 at a legitimate dealer (see counterfeit note above) it is easily my current recommendation for an extremely capable, entry level, VLF nugget detector with general purpose capabilities. I recommend this detector over the Fisher Gold Bug and Gold Bug Pro models below, not only because of the extra capability, but because it can be had stock with the 5" x 10" DD coil, the best general nugget hunting coil for the FT 19 kHz series. It can only be had as an accessory coil on the Gold Bug models, driving their out of pocket cost even higher. Nokta Gold Kruzer ($549, 61 kHz) - Nokta/Makro started shipping the new Gold Kruzer model in June 2018 and with a change in the company name is now simply the Nokta Gold Kruzer. The Gold Kruzer is a variant of the old Makro Gold Racer that has been boosted to 61 kHz from 56 kHz and put in a waterproof housing good to 5 meters (16.4 ft). The Gold Kruzer comes with a 10" x 5" concentric coil and a 4" x 7.5" DD coil. The weight including LiPo batteries is 3.0 lbs. There are four coils available for the Gold Kruzer. Steve's Opinion - The Makro Gold Racer was one of my favorite detectors because until recently there was nothing running in this frequency class that had full target id and other options normally seen only in coin detectors. The Gold Kruzer takes it all to the next step by being waterproof in excess of ten feet. There are no other detectors running at a frequency this high that are fully submersible with built in wireless capability and therefore this detector may find favor with freshwater jewelry hunters as well as prospectors. The Gold Kruzer is worth keeping an eye on, and is a better value than it appears at first glance due to the dual coil packaging. 2024 Note: The Gold Kruzer has been reduced in price from over $600 to only $549 which seriously upsets the cart. This is an incredible value for what you get and well worth consideration. Fisher Gold Bug Pro ($599, 19 kHz) - Essentially the same as the Gold Bug above with the addition of manual ground balance. The target ID makes the Gold Bug Pro good for more than just nugget hunting, and it will find favor with jewelry and relic hunters. The manual ground balance gives expert operators the control they desire to get the best depth possible. This unit normally comes with a 5" round DD coil to enhance the sensitivity to small gold but other standard coil packages are available. Weight including a single 9V battery is 2.5 lbs. Many accessory coils are available for the Gold Bug Pro. Steve's Opinion - The Pro is the final version in this series which saw several early variations including the Gold Bug above. It is a excellent choice for prospecting, relic, or jewelry detecting and does fine as a coin detector also. However, you are now paying a premium for the Gold Bug name, and the more capable Fisher F19 at the top of this list can be had in a better configuration at a much lower price. The Nokta. Unless you just want the name, pass. XP ORX ($599, 14, 28, 56, 80 kHz) - The XP ORX emphasizes gold prospecting and coin detecting in the promotional material. The XP ORX appears to be a version of the "Africa only" Depar DPR 600 made for sales in Europe, the U.S., and elsewhere. The ORX has been refined from that early effort by the addition of the ability to use the new X35 coils. Steve's Opinion - The XP ORX went through some teething pains with coils before settling into its final role as XPs gold nugget detector. I think the ORX is a great little nugget hunter personally (I love the compact design), but it seems to be overlooked my most serious prospectors, and getting more attention as a low cost alternative to the XP Deus for coin and relic detecting. The new lower price makes the ORX a serious contender, a big step up in capability from the Fisher 19 kHz models above, and a little less money than the Garrett 24K below for a more full featured detector. Garrett AT Gold ($639, 18 kHz) - The AT Gold was a totally new concept in metal detecting from Garrett Electronics when it was introduced. This full featured detector has everything you would expect from a dry land detector - LCD display, full control set and functions, speaker, interchangeable coils, and lightweight. But it is submersible to 10 feet! Even the speaker is waterproof. Note that the unit itself may be submerged but if you want to put your head underwater you will need optional submersible headphones. Weight including a four AA batteries is 3 lbs. The stock coil is a 5" x 8" DD elliptical. Many accessory coils are available for the AT Gold. Steve's Opinion - The Garrett AT Gold was an innovative concept when it was introduced, and was the only waterproof nugget detector option at the time. The nugget hunting world has moved past the AT Gold now, and unless it comes down in price it's hard to recommend for somebody interested primarily in a nugget detecting VLF. Only for Garrett fans really, and even then more for the relic hunting crowd. For a much better option, see the Garrett Goldmaster 24K below or one of several less expensive models above, like the Nokta Gold Kruzer. ads by Amazon... Minelab SDC 2300 ($3599, Pulse) - This model is unique as Minelabs first waterproof pulse induction metal detector. A key feature is that the detector is physically packaged in the proven F3 Compact military housing that is waterproof to ten feet and folds down into an incredibly compact package only 15.7" long and weighing 5.7 pounds including four C cell batteries. Steve's Opinion - I have used the Minelab SDC 2300 and I must say I was impressed. The waterproof compact design is perfect for hardcore backpack style prospecting. The main thing however is that the SDC 2300 comes as close to VLF type performance on small gold as you can get while being almost impervious to the ground mineralization, and hot rock issues, that plague said VLF detectors. In fact, the SDC 2300 will find gold nuggets smaller than most good VLF detectors can detect in mineralized ground. The SDC 2300 is also one of the simplest detectors to use and master on the market. The main caveat is that the detector is optimized for small gold with the hardwired coil, and so other ground balancing PI detectors are a better option for large nuggets at depth. It is also nearly twice the price of the Garrett ATX above, and so you are paying quite a premium for a little better performance on small gold. Still, the SDC 2300 is almost impossible to beat for the price, if the goal is just to go find some gold, any gold at all. If the budget allows, however, at this point I would pass, and go to the new Garrett Axiom below, which offers a much more sensible design, with many more coil options, and better capability for larger gold at depth. Garrett Axiom ($3995, Pulse) - A new pulse induction gold nugget detector, just announced for 2022, available by the end of the year. The Garrett Axion is the first pulse induction nugget detector to truly reflect 21st design options and capabilities. The Axiom is a sleek, modern design, perfectly balanced at only 4.2 lbs with the 11" x 7" mono coil. The detector is fully weatherproof, with waterproof coils. The Garrett Axiom is available in a couple package options, but the most popular will include the 11" mono coil, 13" DD coil, and Garrett Z-Lynk high speed wireless headphones. The Axiom has a perfect balance of controls, giving experts more options than more simplistic designs, while still focusing on only the controls really needed, to keep things easy for beginners. Steve's Opinion - Well, I have to admit I'm biased on this one. I lobbied Garrett every way possible for almost a decade, to make a detector like the Garrett Axiom. So it is literally a dream come true for me, a powerful pulse induction detector in a really great, ergonomic package, and at a price that won't break the bank, but honestly still more expensive than I was hoping for. I have used the Axiom already enough to know that it is very competitive although it is not that it is the most powerful option available. For that I refer you to the Minelab GPZ 7000 below. The Axiom goes head to head with the GPX 6000 and basically offers 90% of the performance of that machine for two thirds the price. Minelab GPX 5000 ($3999, Pulse) - This Pulse Induction (PI) unit essentially ignores ground mineralization and most hot rocks. The GPX 5000 is designed specifically for nugget detecting and so it has many adjustments for mineralized ground not available on other PI detectors. The GPX 5000 is the culmination of over 10 years of innovation in pulse induction technology. The GPX weighs 5.3 lbs. not including the harness mounted battery, which weighs another 1.7 lbs. The detector comes with both an 11" round mono coil and 11" round DD coil. Over 100 accessory coils are available for the GPX 5000 (Minelab, Coiltek, Nugget Finder)! And more coils are being released every year. Steve's Opinion - The Minelab GPX 5000 can at this point be considered the reliable, well proven option, for just about any pulse induction task a person wants to consider. It has found a wide audience not just with nugget hunters, but with beach and relic hunters. This is in large part due to the incredible coil selection. For general nugget hunting however, the GPX 5000 faces new competition in the form of the Garrett Axiom above, for almost the same price. The Axiom is a better package from a physical perspective and more capable than the GPX 5000 on bread and butter small gold nuggets. However for 1/2 ounce and larger nuggets the GPX 5000 still has the edge due to it's superior large coil selection. personally I lean Axiom for the ergonomics but a case can be made for either machine depending on the user. Minelab GPX 6000 ($6499, Pulse) - The Minelab GPX 6000 is a new pulse induction model that is just now getting into end user hands. The GPX 6000 is exceptionally light and well balanced compared to previous Minelab models, and promises to set new standards for ease of operation. The GPX 6000 weighs 4.6 lbs. and has three coils available at launch, an 11" round mono, 14" round DD, and 17" elliptical mono. The detector has built in Bluetooth wireless headphone capability and quick release Li-Ion batteries. Steve's Opinion - Minelab beat Garrett to the punch in making a very ergonomic metal detector for the 21st century. The GPX 6000 is an excellent choice for gold prospectors, with out of box sensitivity on smaller gold that exceeds the Minelab GPZ 7000. Sadly, what should have been rave reviews by users, has been muted by persistent issues regarding bad coils and hardware based electrical interference. I admit I feel like I have a little egg on my face, as I raved about the GPX 6000 a lot when it came out since mine had none of the problems that far too many people have been experiencing. Regardless of that, I still think when it is running like it should, the GPX 6000 is a superb detector. The closest competitor is the Garrett Axiom for $2500 less. I do think the GPX 6000 retains a small performance edge over the Axiom but whether it is worth the 50% higher price will depend on the user. The more you use a nugget detector, the less the price difference matters. Minelab GPZ 7000 ($8999, ZVT) - The new Zero Voltage Transmission technology from Minelab takes gold prospecting to the next level. The new platform represents a break from the past SD/GP/GPX series in more ways than one, with a new weatherproof housing design based on the Minelab CTX 3030. The GPZ 7000 weighs 7.32 lbs. and comes with a waterproof 14" x 13" coil. There is one official accessory coil available at this time, plus one officially sanctioned aftermarket coil, but more are coming as I type. Brave souls can check out numerous hacked Russian coil options. Steve's Opinion - It's pretty simple. If you want the most powerful metal detector made for finding gold nuggets, get a Minelab GPZ 7000. The GPX 6000, Garrett Axiom, and even SDC 2300 can beat it out of box on the tiniest gold nuggets. But the 7000 will hit stuff plenty small, and more importantly, deliver the goods on the bread and butter gold that matter most to genuine prospectors who want to put weight in their pocket. The difference in small gold capability can be made up with options aftermarket coils, meeting or exceeding what the other models mentioned can do. Yes, it is heavy, and it is expensive, but most really serious gold prospectors are using the GPZ 7000 for a reason - when it comes to sheer performance, it's the best machine for the job. A Steve's Opinion summary - So maybe all the above is still too much information, too many choices. And you want to ask "what would you do Steve?" Well, I'm not trying to speak for anyone but myself, but here is my current thought on the situation. If you want a really great VLF nugget detector in 2024 at a great price the Nokta Gold Kruzer and XP ORX are standout values at under $600. Both are excellent VLF nugget machines and both can be used for more than just nugget detecting. The Gold Kruzer coming with two coils and being fully waterproof would be my choice. As far as PI goes for me it's either GPX 6000, or Garrett Axiom. If money is no object and you only ever intend to use the machine for nugget detecting, then the 6000 wins the day. For me I do more than just nugget hunt so I find the Axiom to be a better general purpose PI for my uses, even though I am giving up a small edge on small gold nuggets. If sheer power is all it's about, weight, price, nothing else matters, just performance, I still think a person has to go GPZ 7000. Yeah, for specific situations other machines might be better. Heck, a Gold Bug 2 might be better in the right spot! But overall, if I had to pay my bills with gold found, I'd be using a GPZ 7000. If I can offer one final word of advice, it would be to pay particular attention to what experienced nugget hunters are using in any particular region. Do not assume you are going to outsmart them, and find some model they have not already tried, and set aside, as less than optimum. Serious prospectors in any particular location will end up focusing on certain units that do the job. In areas of extreme mineralization this is usually a PI detector. In areas with less mineralization and lots of ferrous trash VLF units often are preferred. If you can discover what models the locals prefer, it will give you a head start in knowing what to use yourself. Above all, whatever detector you finally choose, dedicate yourself to mastering it. It takes at least 100 hours of detecting to become proficient with a detector model. Any less, and you are still practicing. Knowing your detector well is more important than what particular model of nugget detector you own. So there you are. Hopefully this helps some people out. I can be found daily on the Detector Prospector Forums and would be pleased to answer any questions you have on metal detecting and prospecting. Also check out Steve's Guide to Metal Detecting for Gold Nuggets. Sincerely, ~ Steve Herschbach Steve's Mining Journal Copyright © 2002 - 2024 Herschbach Enterprises - Please do not reuse or repost without my express permission.48 points

-

Well, here I am, another year older, and 48 years of metal detecting and gold prospecting under my belt! 2020 has been an odd year for many reasons, the main being the pandemic that has wrecked havoc on life around the planet. The resulting shutdowns and social distancing requirements made this a challenging year for everyone, whether they caught the virus or not. Once I saw where things were headed, I decided to gracefully accept that 2020 would be a good year to just kick back and relax. I did get in some metal detecting during the year, but it has been more about trying out some new detectors than making actual finds. I had a good time and learned a few things, but this was the first year in a long time that I had no specific "adventure" planned for the year. If you look back over my journal, you will see I have done well over the years at making some sort of special prospecting or metal detecting trip each year. This year however it was short day trips, or at most a few overnight outings. Travel did not seem like a good idea this year, especially anything involving airplanes. Some gold found by Steve while metal detecting in 2020 I made finds for the year; gold nuggets, coins, and jewelry. There was no one find however that stands out at all in my mind, more a reflection of how spoiled I am than anything else. In some ways it was a very nice year for me, just taking it easy and having fun. However, I would like to ramp it up for 2021, and I will make the effort in the coming year to try new places and locations more than I did in 2020, which was mostly revisiting old haunts. Happy New Year! ~ Steve Herschbach Copyright © 2020 Herschbach Enterprises Go To Prior Story Journal Index Page22 points

-

Welcome to my free "book" about metal detecting and gold prospecting. Each chapter is a "how to" or explanatory guide, on metal detecting and gold prospecting themes. Many were written in response to questions asked on this websites forum. Each article focuses on a single subject, and they are meant to be relatively short, but to also cover the topic well. In many cases you will not find more in-depth coverage of any of these topics anywhere else. The answers were created expressly to eliminate having to answer common questions repeatedly, creating this reference for use in future threads. There is information both for beginners, and advanced topics for the pros. All articles are copyrighted, and may not be duplicated in any form without my express permission. Steve Herschbach Metal Detecting Steve's Guide to Headphones for Metal Detecting Steve’s Guide to How Deep Metal Detectors Can Go Steve’s Guide to VLF Metal Detectors and “More Depth” Steve’s Guide to Testing Metal Detectors Steve's Guide to Metal Detector "Air Tests Steve's Guide to Metal Detector Search Coil Compatibility Steve's Guide to VLF Concentric vs DD Search Coils Steve's Guide to "Search Coils Are Not Antenna" Steve's Guide to Variations in Coil Performance Steve’s Guide to Detecting Depth Vs Coil Size and Shape Steve’s Guide to Metal Detector Sensitivity Steve's Guide to Sensitivity vs Target ID Stability Steve's Guide to Threshold Autotune, SAT & V/SAT Steve's Guide To Why GB Numbers Do Not Indicate Mineralization Levels Steve's Guide to Metal Detector Mixed Modes Steve's Guide to Metal Detectors with Reliable Target ID Numbers Steve's Guide to the Best Target IDs For Rings Steve's Guide to Detecting Gold Jewelry Versus Aluminum Steve’s Guide to Why Detecting Thin Gold Chains Is Difficult Steve's Guide to Detecting Tiny Gold Jewelry In Saltwater Steve's Guide to Small Item Testing "The BIC Pen Test" Steve's Guide to Testing Weak Gold Targets & Ground or Salt Settings Steve's Guide to Selectable Frequency & Multifrequency Metal Detectors Steve's Guide to Why Target ID is About Size, Not Type of Metal Steve’s Guide to Metal Detector Discrimination Basics Steve’s Guide to Recovery Speed Steve’s Guide to Target ID Normalization Steve's Guide to Target Masking Differences Euro vs U.S. Steve’s Guide to Why Weak Non-Ferrous Targets Read As Ferrous Steve's Guide to Why Some Ferrous Reads Non-Ferrous Steve’s Guide to Iron Bias (Bottle Cap Reject) Steve's Guide to Waterproof VLF Metal Detectors Steve's Guide to Beach Detecting For Gold Prospectors Steve’s Guide To Why Detecting Tiny Gold In A Bottle Is Difficult Steve's Guide to VLF vs PI Depth Difference Steve's Guide to Pulse Induction Ground Balance Steve's Guide to Pulse Induction Discrimination Steve's Guide to Ground Balancing PI and "The Hole" Steve’s Guide To More About The PI “Hole” Steve's Guide to Long Range Locators (LRLs) Steve's Guide to the Fisher CZ Series Metal Detectors Steve's Guide to Fisher Gold Bug Models Steve's Guide to The F75 Ferrous Tone Quirk Steve's Guide to Minelab BBS, FBS, FBS2, and Multi-IQ Steve's Guide to Minelab E-trac, CTX 3030, Excalibur, and Equinox Steve's Guide to Differences Between Minelab SD, GP, & GPX Steve's Guide to Minelab GPX Timings Steve's Guide to Tuning the Minelab GPX 5000 Steve's Guide to Insanely Hot Settings For The GPZ 7000 Steve's Guide to Ground Tracking As A Filter Steve's Guide to White's Goldmaster Models Steve's Guide to White's SignaGraph Display Steve's Guide to White's Electronics GMT versus MXT Steve's Guide to White's TDI Coin Settings Steve's Guide to Rebuilding The White's GMT Steve's Guide to Some Nugget Detectors of Note Metal Detector Database with User Reviews Prospecting Steve's Guide to How to Pan for Gold Steve's Guide to Suction Gold Dredges Steve's Guide to Where To Prospect For Gold Steve’s Guide to Getting A Mining Job In Alaska Steve’s Guide to Metal Detecting for Gold Nuggets Steve's Guide to Gold Nugget Detectors Steve's Guide to a Brief History of Gold Nugget Detectors Steve's Guide to Gold Nugget Target ID Numbers Steve’s Guide to Glaciers & Gold Steve’s Guide To Detecting Gold In Quartz Rock & Mine Dumps Steve's Guide to Finding Gold Veins With A Metal Detector Steve’s Guide to Nugget Detecting Kits Gold Prospecting Research Material For Alaska General Steve's Guide to Successful Rock Tumbling Metal Detecting & Prospecting Library Catalogs, Brochures, User Guides, & Owner's Manuals Thread Hall of Fame Nail Board Tests & Sensitivity21 points

-

The secret to the Minelab GPX series is thoroughly understanding the timings and when to use each one. Timings are variations of the basic pulse induction technology at work in the GPX series that gives you far more flexibility than exists in other pulse induction detectors. Unfortunately this extra flexibility also adds complexity, and so it is not unusual that some people may not be using the optimum settings in many cases. It is very important when investing in a Minelab GPX detector to take the time to read the manuals and study until you fully understand what the settings do and how to adjust the detector for the best performance. Otherwise you will not be getting all the potential out of your investment. The chart below shows the timings and what GPX models they are available on along with a general description. The descriptions are from the owners manuals that are available by download at the bottom of the page. In general you should always use timings as near the top of the chart as possible, with the exception of the Salt settings. Those are for alkali flat and salt water beach areas only. Using timings designed for more mineralization than is actually required may result in less depth on desired targets. Imagine the timings as another sort of ground balance setting. Low mineral settings are more powerful than high mineral settings and should be used whenever possible. Some confusion is the result of the timing names. Some people assume the Fine Gold timing is best for fine gold. This does make a sort of sense, but the fact is Fine Gold is just better than other high mineralization timings on smaller gold. In milder ground Sensitive Extra will obtain better results on small shallow gold. It is also very important to know that some timings work better with one coil type or the other. Minelab GPX Timings Chart Little or No Mineralization Coin/Relic (GPX 4800, 5000 ONLY) Coin/Relic is for use in lightly mineralized soils including many beaches and loamy soils. It offers maximum detection depth on a range of target sizes, significantly greater than any other timings. However, if the ground is any more than lightly mineralized, the detector may not ground balance properly. On ocean beaches containing significant quantities of black sand, better results may be had by using Normal or Salt settings. Mild Mineralization Sharp (GPX 4500, 4800, 5000) Sharp is similar to Normal but creates a more powerful detection field. It is capable of an improvement in depth, but is more susceptible to interference and will increase the severity of false signals in difficult grounds. This timing is best used in quiet conditions and can work well in combination with Deep Search Mode with a reduced Rx Gain setting. Sharp is an excellent tool for pinpointing faint signals due to the very "sharp" signal response. Sharp will work best with DD coils in most gold field locations. Medium Low Mineralization Sensitive Extra (GPX 4000, 4500, 4800, 5000) This timing may increase the signal from certain hot rocks near the surface, but can actually help smooth out the Threshold in certain ground types, particularly with Double-D coils. In mild ground conditions Sensitive Extra will provide the best signal response on a small, deep target. Medium Mineralization Normal (GPX 4000, 4500, 4800, 5000) Normal gives you the best performance on a wide range of soil conditions, and it will provide the best depth on a wide variety of target sizes. It works particularly well with the supplied 11" DD search coil for general detecting. You should always use Normal in new areas where you are unsure of the soil mineralization and the depth of targets. Medium High Mineralization Salt Coarse (GPX 4000, 4500, 4800) The effect of alkaline salt mineralization is vastly different to the effect of ironstone and mineralized clays. Normal should be tried first in these areas, but if the Threshold is too unstable then better performance will be obtained in Salt-Coarse. Using the Salt-Coarse timing may result in a loss in signal response to smaller targets. However, the response on larger items remains relatively unaffected and ground noise is usually minimized. Medium High Mineralization Salt/Gold (GPX 5000 ONLY) Provides the best signal response on small to large gold in salt saturated and mineralized ground conditions. It should work well on dry inland salt lakes, high salt concentrated goldfields, and mineralized saltwater beaches. Extremely salt saturated soils may still need to be searched with the coil switch in Cancel (using a Double D coil). High Mineralization Fine Gold (GPX 5000 ONLY) Fine Gold is sensitive to smaller targets in highly mineralized ground. It provides a sharper signal on small gold compared to Enhance, and improves the detectability of rough/flaky gold and specimens, while ignoring most hot rock signals and false ground noises. Shallow, highly mineralized ground where gold has been found previously should be re-examined with Fine Gold, and best results will be had by using the optional 8” and 11” Commander Monoloop coils. Note: Sensitive Extra will provide superior results on small gold in milder ground. Very High Mineralization Enhance (GPX 4500, 4800, Improved in GPX 5000) Runs quietly in most heavily mineralized, variable and "hot rock" infested grounds using a monoloop coil. It is more sensitive and detects deeper than Sensitive Smooth but can be slightly more affected by severe ground mineralization. Severe Mineralization Sensitive Smooth (GPX 4000, 4500, 5000) Sensitive Smooth is optimized for an improved response on smaller, shallow nuggets in severe soils. There is a loss of depth on bigger targets; so you should not use this setting when seeking out large, deep nuggets. Sensitive Smooth is best suited for use with monoloop coils in difficult soils. It eliminates most false signals from hot rocks, and ground mineralization, whilst retaining excellent sensitivity to small targets. The example below shows three common timings and where they should be used. It also highlights why using the wrong timing for the conditions can result in missed targets. Minelab Mineralization and Timing Example The following chart illustrates the procedure for finding the correct timing for each situation. In general, always start with the Normal timing. If the detector is stable and quiet, try timings on the left - Sensitive Extra, Sharp, or in rare cases, Coin/Relic. If ground noise or hot rocks present problems in Normal, then try timings on the right - Fine Gold, Enhance, or Sensitive Smooth. Salt settings should generally only be used on alkali ground (salt flats) or salt water beaches, but may have applications in other ground. The goal is always to find the most powerful setting that allows for stable operation. Each timing can be adjusted within certain parameters, primarily through the use of the Gain and Stabilizer settings. Adjusting for a lower Gain, for example, may be preferable to going to a less powerful timing. Minelab GPX Timing Selection Chart - Click on image for larger version Finally, each timing may work best with a certain type of coil (DD or Mono) and the timings have varying level of resistance to Electro Magnetic Interference (EMI). The matrix below attempts to show which timings offers which benefits and strengths/weaknesses. Minelab Timing Coil EMI Matrix - Click on image for larger version The simple chart below can be printed out and taped or glued on your detector shaft as a reminder in the field as to which timing may be best. Click on the image to download a large version. Minelab Timing Decal - Click on image for larger version Minelab GPX 4800/5000 Instruction Manual Download Here Minelab GPX Series Quick Start Guide Download Here Beginner's Guide to Tuning the Minelab GPX 5000 Minelab GPX 4800/5000 Product Brochure Download Here Minelab Commander Coil Brochure Download Here Minelab GPX 4500 Instruction Manual Download Here Minelab GPX 4000 Instruction Manual Download Here ~ Steve Herschbach Copyright © 2011 Herschbach Enterprises16 points

-

When Minelab started developing our EQUINOX detector, we looked very closely at all of the current market offerings (including our own) to reassess what detectorists were really after in a new coin & treasure detector. A clear short list of desirable features quickly emerged – and no real surprises here – waterproof, lightweight, low-cost, wireless audio, and of course, improved performance from new technology. This came from not only our own observations, but also customers, field testers, dealers and the metal detecting forums that many detectorists contribute to. While we could have taken the approach of putting the X-TERRA (VFLEX technology) in a waterproof housing and adding a selectable frequency range, this would have been following the path of many of our competitors in just rehashing an older single frequency technology that had already reached its performance limits. Another option would have been to create a lower cost waterproof FBS detector, but that also had its challenges with FBS being ‘power hungry’, needing heavier batteries, heavier coils, etc., and relatively high cost compared to the more recent advances that our R&D team have been making with the latest electronics hardware and signal processing techniques. When Minelab develop a new detecting technology we aim to create a paradigm shift from existing products and provide a clear performance advantage for our customers. Our Technology History The multi-frequency broad band spectrum (BBS) technology that first appeared in Sovereign detectors in the early 1990’s provided an advantage over single frequency coin & treasure detectors. This evolved into FBS with Explorer, all the way through to the current CTX 3030 (FBS 2). The multi-period sensing (MPS) PI technology that first appeared in the SD 2000 detector in the mid 1990’s gave a significant advantage over single frequency gold detectors. This key technology exists in the current GPX Series detectors today. Zero Voltage Transmission (ZVT) is our latest gold detection technology implemented in the GPZ 7000 and is a recent example of Minelab’s continued innovation beyond ‘tried and true’ technologies to achieve improved performance. Further to our own consumer products, our R&D team also has significant experience working with the US and Australian military on multi-frequency technologies for metal detection. Introducing Multi-IQ Multi-IQ is Minelab’s next major innovation and can be considered as combining the performance advantages of both FBS and VFLEX in a new fusion of technologies. It isn’t just a rework of single frequency VLF, nor is it merely another name for an iteration of BBS/FBS. By developing a new technology, as well as a new detector ‘from scratch’, we will be providing both multi-frequency and selectable single frequencies in a lightweight platform, at a low cost, with a significantly faster recovery speed that is comparable to or better than competing products. We have come out with a very bold statement that has captured a lot of market attention: “EQUINOX obsoletes all single frequency VLF detectors” Multi-IQ achieves a high level of target ID accuracy at depth much better than any single frequency detector can achieve, including switchable single frequency detectors that claim to be multi-frequency. When Minelab use the term “multi-frequency” we mean “simultaneous” – i.e. more than one frequency is transmitted, received AND processed concurrently. This enables maximum target sensitivity across all target types and sizes, while minimizing ground noise (especially in saltwater). There are presently only a handful of detectors from Minelab and other manufacturers that can be classed as true multi-frequency, all of which have their own advantages and disadvantages. How does Multi-IQ compare to BBS/FBS? Multi-IQ uses a different group of fundamental frequencies than BBS/FBS to generate a wide-band multi-frequency transmission signal that is more sensitive to high frequency targets and slightly less sensitive to low frequency targets. Multi-IQ uses the latest high-speed processors and advanced digital filtering techniques for a much faster recovery speed than BBS/FBS technologies. Multi-IQ copes with saltwater and beach conditions almost as well as BBS/FBS, however BBS/FBS still have an advantage for finding high conductive silver coins in all conditions. “* 20 kHz and 40 kHz are not available as single operating frequencies in EQUINOX 600. The Multi-IQ frequency range shown applies to both EQUINOX 600 and 800. This diagram is representative only. Actual sensitivity levels will depend upon target types and sizes, ground conditions and detector settings.“ Questions & Answers What actually is Multi-IQ technology? What does the name stand for? What frequencies does it use? Is “Multi” the same or different for the various Detecting Modes? Is Multi-IQ the same or different for EQUINOX 600 and EQUINOX 800? Why use a single frequency? How does EQUINOX perform in certain environments? How does EQUINOX perform compared to other Minelab detectors? How does EQUINOX perform against other brand detectors? These are some of the myriad of questions we have seen since we published our EQUINOX Product Notice in mid-September. Some of the answers will have to wait until Minelab publishes reports from our field testers and/or you get your own hands on a detector to try yourself. In the meantime, let’s look further into the aspects of Multi-IQ technology. Multi-IQ is derived from: Simultaneous Multi-Frequency In-phase and Quadrature Synchronous Demodulation. We can go to a statement from Dr Philip Wahrlich, our principal technology physicist, about a key difference of Multi-IQ compared to the demodulation taking place in conventional single frequency VLF detectors: “Within the Multi-IQ engine, the receiver is both phase-locked and amplitude-normalized to the transmitted magnetic field – rather than the electrical voltage driving the transmitted field. This field can be altered by the mineralization in the soil (in both phase and amplitude), so if the receiver was only phased-locked to the driving voltage, this would result in inaccurate target IDs and a higher audible noise level. Locking the receiver to the actual transmitted field, across all frequencies simultaneously (by measuring the current through the coil) solves these issues, creating a very sensitive AND stable detector” Precisely measuring these extremely small current variations is quite remarkable if you consider the levels involved. It’s actually parts per billion, or nanoamp signals, we are talking about here! With Multi-IQ, we can derive much greater target ID accuracy and increased detecting performance, especially in ‘difficult’ ground. In ‘mild’ ground, single frequency may perform adequately, BUT depth and stable ID’s will be limited by ground noise; whereas the Multi-IQ simultaneous multi-frequency will achieve maximum depth with a very stable target signal. In ‘strong’ ground, single frequency will not be able to effectively separate the target signal, giving decreased results; whereas Multi-IQ will still detect at depth, losing a minimal amount of target accuracy. This is how we would generally represent the multi-frequency advantage, based on our engineering test data. Let’s hear more from Philip Wahrlich about the technical details: “For each frequency the detector transmits and receives there are two signals which can be extracted which we refer to as I and Q. The Q signal is most sensitive to targets, while the I signal is most sensitive to iron content. Traditional single-frequency metal detectors use the Q signal to detect targets, and then use the ratio of the I and Q signals to assess the characteristics of the target and assign a target ID. The problem with this approach is that the I signal is sensitive to the iron content of the soil. The target ID is always perturbed by the response from the soil, and as the signal from the target gets weaker, this perturbation becomes substantial. With some simplification here for brevity, if a detector transmits and receives on more than one frequency, it can ignore the soil sensitive I signals, and instead look at the multiple Q signals it receives in order to determine a target ID. That way, even for weak targets or highly mineralized soils, the target ID is far less perturbed by the response from the soil. This leads to very precise target IDs, both in mineralized soils and for targets at depth.” “How many simultaneous frequencies?” you may ask, wondering if this is a critical parameter. Minelab has been carrying out detailed investigations into this in recent years. Just as you can color in a map with many colors, the minimum number to differentiate between adjacent countries is only 4 – a tough problem for mathematicians to prove, over many years. Similar to the map problem, it’s perhaps not the maximum number of frequencies needed to achieve an optimum result, but the minimum number that is more interesting. When it comes to frequencies in a detector, to cover all target types, how the frequencies are combined AND processed is now more important, with the latest detectors, than how many frequencies, for achieving even better results. Efficient new technology = lower power = lighter weight = higher performance. The above diagram is intended to be a simplified representation of how different frequencies of operation are better suited to different target types; i.e. low frequencies (e.g. 5kHz) are more responsive to high conductors (e.g. large silver targets) and high frequencies (e.g. 40kHz) are more responsive to low conductors (e.g. small gold nuggets). The EQUINOX 600 offers a choice of 3 single frequencies and the EQUINOX 800 offers the choice of 5 single frequencies. Both models also have simultaneous multi-frequency options that cover a much broader range of targets than any one single frequency can – and they’re different across the Detecting Modes! Our goal was to develop a true multi-purpose detector that could not only physically be used in all-terrain conditions, but also be suitable for all types of detecting for all detectorists, and particularly those not requiring a specialist premium flagship detector optimised for only one aspect of detecting – e.g. coins, beach, gold, jewelry, water, discrimination, artefacts, etc. This multi-purpose requirement is something that could only be achieved by going beyond single frequency and creating the next generation of multi-frequency technology. Equally adaptable to all target types and ground conditions – just select your detecting location and go! An important update on the Detect Modes… Previously we have stated that Park, Field and Beach would run in multi-frequency and that Gold would only use the single frequencies of 20kHz and 40kHz, giving better results for gold nugget hunting. Our ongoing collaborative field testing feedback from around the world has resulted in further improvements to Multi-IQ to the point where multi-frequency is now the best option for Gold Mode as well, and will be the default setting. Please refer to the revised Getting Started Guide for updated product functions. Now, back to the technology: looking into our Multi-IQ diagram further… a single frequency is most sensitive to a narrow range of targets and multiple frequency is equally sensitive to a wider range of targets (e.g. the orange curve versus the white curve below). According to Philip Wahrlich, “From our testing, the Multi-IQ deployed in EQUINOX detectors has shown no significant trade-offs relative to the best single-frequency detectors and exceeded performance benchmarks in many important attributes, especially discrimination. And, for good measure, EQUINOX can also be operated as a single-frequency detector” While we could delve into this aspect further, many of our readers are likely more interested in what happens within the white Multi-IQ band itself, rather than single versus multi. What has Minelab developed new, and uniquely, with frequencies to give better performance across the whole range of targets for different conditions? The Multi-IQ transmit signal used in EQUINOX is a complex waveform where multiple frequencies are combined in a very dissimilar way than our proven BBS/FBS technology in Excalibur II / Safari / E-TRAC / CTX 3030 detectors. If you view the BBS signal amplitude on an oscilloscope, it looks something like this: In comparison, Multi-IQ looks something like this: Hence – Multi-IQ is not a derivative or evolution of BBS/FBS. Multi-IQ is a DIFFERENT method of simultaneous multi-frequency metal detection. We could also debate “simultaneous” versus “sequential” semantics; however the real detection ‘magic’ doesn’t happen with what is transmitted to and received from the coil alone. Remember, in Part 2, we discussed how frequencies are “combined AND processed” as being important for achieving better results? Let’s assess Multi-IQ for the different Detect Mode search profiles: Park 1 and Field 1 process a lower weighted frequency combination, as well as using algorithms that maximise ground balancing for soil, to achieve the best signal to noise ratio. Hence being most suited for general detecting, coin hunting, etc. Park 2 and Field 2 process a higher weighted combination of the Multi-IQ band while still ground balancing for soil. Therefore they will be more sensitive to higher frequency (low conductive) targets, but potentially more susceptible to ground noise. Beach 1 also processes a lower weighted combination, BUT uses different algorithms to maximise ground balancing for salt. Hence being most suited for both dry and wet sand conditions. Beach 2 processes a very low weighted frequency combination, using the same algorithms as Beach 1 to maximise ground balancing for salt. This search profile is designed for use in the surf and underwater. Gold 1 and Gold 2 process the higher weighted combination of the Multi-IQ band while still ground balancing for soil. However, they use different setting parameters better suited for gold nugget hunting. Earlier we discussed the different Multi-IQ “frequency weightings” for the different search profiles. Now let's explain further why it is not a simple matter of just referring to specific individual frequencies for learning more about Multi-IQ technology. Let’s now consider one of the key practical detecting outcomes and then discuss how this was achieved… “A lot of people are going to be surprised at how well the machine works in saltwater. At the outset we weren’t sure whether reliably detecting micro-jewelry in a conductive medium was even possible, but – with the help of our field testers and the subsequent fine-tuning of the Multi-IQ algorithms – we’ve found the EQUINOX to be more than capable.” Dr Philip Wahrlich Background and considerations While Multi-IQ may appear as ‘magic’ to some, to our team of signal processing experts, it’s the result of a significant number of man-years of development. So where did they start? By assessing the metal detectors and technologies available in the market at that time, along with typical customer perceptions about their practical applications; and actual detecting results achieved: So, an important goal with developing Multi-IQ technology was to retain the above simultaneous multi-frequency advantages AND greatly improve performance in the two key areas where many single-frequency detectors typically excel – fast recovery in iron trash and finding low conductors in all conditions. Speeding up the process Most comparable low-power Continuous Wave transmit-receive detectors (for the same coil size) will have a similar raw detection depth at which the transmit signal penetrates the ground and has the potential to energize a target. To increase detection depth significantly typically requires higher power and Pulse Induction technology. This has advantages for gold prospecting, but discrimination is poor for identifying non-ferrous targets. While we continue to push for depth improvements, Multi-IQ also aims to provide substantial speed improvements, resulting in being able to better find ALL non-ferrous targets among trash in ALL locations. You could therefore say “fast is the new deep, when it comes to EQUINOX!” Let’s start with considering signal processing not as a ‘black box’ where ‘magic’ happens, but more as a complex chain of applied algorithms, where the goal is to more accurately distinguish very small good target signals from ground noise, EMI and iron trash. Now, ‘fast’ by itself is not enough – you can have fast with poor noise rejection and poor target identification, giving no great advantage. Fast is also not just a result of microprocessor speed. Processors operate at much higher speed than is needed to ‘do the signal processing math’. You can think of the signal processing chain broadly as a set of filters and other processes which are applied to the metal detector signals to convert these signals into useable, informative indicators, such as an audio alert or a target ID. For Multi-IQ, keeping the ‘good’ properties of these filters, while keeping them lean and removing unnecessary processing, was an important step towards achieving ‘fast’ for EQUINOX. It’s also important to recognize that these filters are not the coarse filters of the analogue electronics hardware of last century – it all happens in software these days. Perhaps think of the older analogue TV standards versus current digital TV. (Standard digital HDTV has approx.10 times the resolution of analogue NTSC.) With metal detectors, a fast higher resolution filter set will result in improved target recognition. Factoring in the ground conditions However, speed without accuracy is not enough to produce a “game changer” detector – and improved accuracy cannot be achieved with a single frequency alone. Why? – “multi-frequency has more data-points” Philip Beck, Engineering Manager. This is worth explaining in more detail… All transmit-receive detectors produce in-phase (I) and quadrature (Q) signals that can be processed in various ways depending upon the response received from targets, ground and salt. This processing happens through ‘channels’ that have different sensitivities to the different signals received. It is important to recognize that channels are not exactly frequencies. This is why it is more complex to explain than just correlating optimum frequencies to specific target types. With a single frequency detector there are two basic channels for information (i.e. I and Q) that respond differently to good and bad signals, depending upon the frequency of operation and whether you are looking the the I or Q signal. It is also possible to scale and subtract these signals, while taking ground balance into account, to best maximize good signals and minimize bad signals. You could thus think of single-frequency being Single-IQ, with a limited set of data (e.g. I, Q, I-Q, Q-I) that works well for a particular set of conditions. To further enhance performance for a different set of conditions, you need to change frequency and detect over the same ground again. Therefore a selectable single frequency detector has an advantage with more data available, but not all at once (e.g. I1, Q1, I1-Q1, Q1-I1 OR I2, Q2, I2-Q2, Q2-I2 for as many frequencies that you can select from). Now, getting back to Philip Beck’s “more data-points”, and just looking at two frequencies, a simultaneous multi-frequency detector would be able to process (for example) I1, Q1, I1-Q1, Q1-I1 AND I2, Q2, I2-Q2, Q2-I2 AND I1-Q2, Q2-I1, I2-Q1, Q1-I2 to give better detection results. Increase the number of frequencies further and the number of extra data-points also increases accordingly. What Multi-IQ does is process different optimized channels of information (not just individual frequencies) for the different modes. We have previously explained this as “frequency weighting” (in Part 3), where the various EQUINOX Search Profiles are matched to the respective ground conditions and target types. Here is a very simplified example where you can see the result of processing more than a single channel of information (remember, a channel is not a frequency): Channel 1 has a strong target signal, but the salt signal is stronger still. Channel 2 has weaker signals for soil, salt and the target. If the detector just responded to either Channel 1 or Channel 2, the target would not be heard through the ground noise. If the detector processes a subtraction of the channels (e.g. ch.1-ch.2), then it is possible to ignore the ground noise and extract a strong target signal. Now, think back to the high number of possible combinations of I and Q for simultaneous multi-frequency compared to single-frequency and the frequency weightings for the modes. All of the EQUINOX Park, Field, Beach and Gold Search Profiles have dedicated signal processing to best suit the conditions and types of targets being searched for. Conclusion Multi-IQ = more data-points = sophisticated processing = better ground noise rejection = more finds Just as targets are more sensitive to certain frequencies, so is the ground – an important reason why air testing has inherent limitations when comparing detector performance. As soon as you have ground to consider in the signal processing equation, it can greatly impact on the ability of a single-frequency detector to accurately identify a target. Also, the deeper a target is buried, the weaker the target signal is, relative to the ground signal. The most difficult ground response to eliminate is the salt response, which varies greatly between soil, dry sand, wet sand and seawater. It is not possible to eliminate the salt response and the soil mineralization response (e.g. black sand) with just one frequency. However, within the carefully calibrated Multi-IQ channels, EQUINOX is able to identify both signals and therefore mostly ‘reject’ them (just as you would notch discriminate an unwanted target) BUT still detect gold micro-jewelry. The above article is a compilation of a series of blog entries taken from Minelab's Treasure Talk. More will be added here as available.15 points

-

I became involved in metal detecting and gold prospecting at an early age and have been at it now for over 45 years. My quest has taken me all over the world and this journal documents many of those adventures. I hope to offer an idea of what can be done by one person with relatively inexpensive equipment. Keep in mind I have been doing this most of my life, and that I am familiar with the areas I am working. I don't want to imply you can just jump right in and have the same results I have. On the other hand, if one works at it, the rewards can be immense. I'm not talking about just the gold and other finds, but the sheer fun and adventure of the search! So here we go, with the successes, and occasional failures, of a prospector and detectorist from Alaska. Steve with 14.1 Dwt Nugget found at Ganes Creek, Alaska The reuse of these stories and images is strictly protected under the copyright laws. You may not do so without my express permission. Image reuse on other websites will normally only require a credit and a link back to this page... but only if I am notified in advance for permission. This Journal is dedicated to my wife for encouraging and supporting my adventures, and to my father for getting me started on the search for gold. ~ Steve Herschbach 2023 - Over 50 Years of Metal Detecting & Gold Prospecting Garrett Axiom in Australia September 2022 2020 - Year of the Pandemic Hunting Ancient Gold in England October 2018 Minelab Equinox Finds Silver Fall 2017 Minelab GPZ 19 Gets First Gold June 8, 2017 Gold Specimen With GPZ 7000 November 1, 2016 Garrett ATX Return To Hawaii April 10, 2015 Nevada Gold With The Garrett ATX September 9, 2014 California With Nokta FORS Gold October 11, 2014 Minelab SDC 2300 Finds Tiny Gold August 24, 2014 Detecting Hawaii With Garrett ATX February 4, 2014 Gold Detecting with Garrett ATX November 20, 2013 Fisher F75 Strikes Gold in Alaska! June 2013 Alaska Gold Dredging 2013 January 2013 2011 Australia Gold Adventure Ganes Creek with F75 and GPX 5000 June 2011 Alaska Gold with Minelab GPX 5000 September 2010 Detecting Micro Gold at Crow Creek September 13, 2009 Minelab X-Terra 50 at Cabo Spring 2006 Beach Detecting with GP 3500 Fall 2005 White's Surf PI & Platinum in Hawaii December 18, 2004 Coin Detecting with Garrett Infinium 2004 MORE STORIES BELOW THE AD Garrett Axiom in Alaska August 2022 Steve’s 2019 UK Adventure September 2019 The Chisana Story 1973 - 2018 XP Deus 74 Khz Elliptical Coil July 22, 2017 Gold With Minelab Gold Monster May 7, 2017 Nevada Gold With GPZ 7000 June 29, 2015 Minelab GPZ 7000 Eureka Moment March 11, 2015 Nokta Scores Gold Specimen Fall 2014 Sore Feet And Gold September 3, 2014 Steve's 2014 Alaska Gold Adventure Steve's 2013 Alaska Gold Adventure Gold and Silver with the Garrett ATX November 2013 Making Lemonade Out of Lemons May 2013 Last Visit to Ganes Creek June 2012 Fisher F75 & Gold Nuggets June 2011 Ancient Coins at Colchester, UK October 1, 2010 Moore Creek Gold Treated with Acid May 2010 White's TDI at Moore Creek, Alaska Summer 2008 White's M6 & Surf PI Pro in Hawaii December 20, 2005 Bulldozer Adventure (Moore Creek) Fall 2004 & Spring 2005 George's Moore Creek Nugget July 2004 Moore Creek Permits & Gold June 2004 MORE STORIES BELOW THE AD ads by Google... Garrett Infinium at Moore Creek Fall 2003 Moore Creek, Alaska June 28, 2003 GP Extreme in the Fortymile May 23, 2003 Shadow X5 at Crow Creek September 18, 2002 Detector Reps at Ganes Creek June 17, 2002 First Gold with White's GMT May 11, 2002 Minelab SD2200D at Fortymile August 18, 2001 Exploring Petersville, Alaska August 5, 2001 Gold Layers at Crow Creek June 15, 2001 Fall Mining at Mills Creek September 16, 2000 Where Gold Comes From August 13, 2000 GPAA Claims at Mills Creek June 24, 2000 Spring Gold Dredging at Crow Creek May 2000 Sniping for Gold at Mills Creek October 24, 1999 4" Subsurface Dredge at Crow Creek October 9, 1999 Gold Dredging at Mills Creek October 2, 1999 5" Subsurface Dredge at Mills Creek August 21, 1999 Mills Creek Cooperative July 17, 1999 About Subsurface Gold Dredges June 24, 1999 Tesoro Lobo at Crow Creek May 23, 1999 Origin of Gold at Crow Creek May 8, 1999 Canyon Dredging at Crow Creek April 24, 1999 Winter Dredging at Crow Creek Fall 1996 Minelab GP 3000 at Moore Creek August 7, 2003 GP 3000 & MXT Get Fortymile Gold June 6, 2003 Garrett Infinium in Hawaii February 18, 2003 Infinium & MXT at Ganes Creek August 29, 2002 Memorial Day at Ganes Creek May 25, 2002 30 Years with White's Detectors 1972-2002 Lode Gold at Hatcher Pass August 12, 2001 Detecting Gold at Ganes Creek June 22, 2001 Crow Creek Nugget Rescue November 4, 2000 Detecting Gold in the Fortymile September 1, 2000 Detecting Gold at Chisana July 21, 2000 Minelab SD2200D at Crow Creek June 10, 2000 Gold in Hawaii Winter 1999 Sluicing Gold at Crow Creek October 17, 1999 Metal Detecting at Mills Creek October 5, 1999 Gold Mining at Mills Creek September 5, 1999 4" Subsurface Dredge at Mills Creek August 15, 1999 Old Stream Layers at Crow Creek July 10, 1999 Detecting Small Gold at Crow Creek May 30, 1999 Flooded Out! of Crow Creek Goldmaster & SD2200D Detectors May 15, 1999 What's Placer Gold Worth? May 1, 1999 First Nugget with a Metal Detector 1973 - 198914 points

-

I recently treated myself to a metal detecting holiday to the area around Colchester, England. This was a reprise to a trip I made to the UK in 2010 in search of Celtic gold. Gold was not in the equation for that trip, but I did find the oldest coins and artifacts I have ever found.... as in 2000 years older than anything I have found before! Colchester has history reaching back into prehistoric times, and is generally acknowledged as the location of Britain's first city. Celtic tribes were active in the area, leaving behind many Celtic gold coins to be found by modern day detectorists. The Romans were also very active in the area, as were other invaders, leading to finds from many cultures across the centuries. I made a return visit to Colchester in 2018, this time relying heavily on the new Minelab Equinox metal detector as my detector of choice. I also had the opportunity to use the new Minelab Equinox 15" x 12" DD coil while on this trip. Not only did I have a very successful trip, but I got to observe other great finds made by the other detectorists in the group. All in all this was a very exciting metal detecting experience that I enjoyed thoroughly. The links below outline both my own experiences and the same trip told from the perspective of another person on the same adventure. Steve's 2018 UK Adventure by Steve Herschbach My UK Trip .... Double Ancient Gold! by Ill Digger Steve Herschbach finds ancient UK gold!14 points

-

There are a few key things to know about headphones for use with metal detectors. The most important thing is to know that some detectors operate in mono, and some in stereo. If you mismatch headphones you can end up with audio in one ear only, or none at all. In fact, this has happened to me. I took my White's DFX out to do a little detecting, and grabbed an old pair of Fisher Phones I had around, and when I got out I found the phones would not work on the DFX. So most detector phones have a stereo/mono switch, or are specially wired to work either way. Make sure your headphones match your detector for stereo or mono operation. But best case is to only use headphones that can do both so you can use them with any detector. You never know when they might get put to use on a different machine. In a situation where you are determined to use a mono headset on a stereo detector or vice-versa plug in adapters can be purchased at most electronics supply houses. 99% of the detectors out there have a 1/4" headphone plug, but many generic headphones have a 1/8" plug. Sure, you can use an adapter, but it just adds a weak spot in the system. So get a 1/4" plug unless your detector is one of the rare 1/8" models. Again, pay attention to the mono versus stereo issue. The good news is that if you make a mistake there is almost always an adapter that will fix the problem but it is best to try and get the correct match. Does your detector have a volume control? Many do not. It is best to buy headphones that have their own volume controls, so you can use them with detectors that do not have a volume control. Again, you never know when you might switch detectors. Ohm matching can be important, and generally higher ohms is better. This is not always true however and some detectors do work better with lower ohm rated models. It is usually easy to determine what the headphone ohm is but almost impossible to know what the detector rating is. I therefore recommend that you should have your detector in hand and be trying the headphones before you buy them instead of going by specs on this point. Things to look for: 1. How do they sound? Are targets sharp and clear to your ear? If not, you can now pass on this set and try another. Different headphones match up with different machine and different ears in such a way that nothing short of trying them can sort this point out. They either sound good to you personally, or they do not. It does not matter what your friend likes. Some detectors allow you to change the pitch from high to low. Try different pitches with your detector to see what sounds best. How do faint targets sound to your ear? People have different frequency responses, some like low tones and some high, and the type of speaker wired into the headphone can make this sound vary a lot. Get a set of headphones that make faint signals as clear as possible to your particular ear. 2. Assuming they sound good, how adjustable is the volume? A good match will give you the ability to fine tune the sound with the volume control on the headphone. In other words, the volume control will have some range. If you have very high ohm headphones and use them on a high volume machine that has no volume control, the headphones may be so loud you have to set the volume on the headphone nearly off. And then tweak it within a fraction of a turn. Some headphones are too powerful for some detectors! The volume control should run from off at one end and too loud at the other, with lots of adjustment in between. 3. How many volume controls are there? Some people like two, one for each ear. This can be great if you have poor hearing in one ear and need to compensate. I personally prefer a single control that works both ears at the same time, so I do not need to fiddle two controls. So this is a personal preference thing, but your headphones should have one or two headphone volume controls. A note on setting your headphones. Turn the detector volume all the way up, if it has a volume control. Turn your headphones all the way down, then turn on your machine and wave it over a large metal item. Turn the headphones up until the loudest sound you will get over a large item is not so loud as to damage your hearing. Now, set the threshold sound on your detector for a faint buzz. You should now be able to hear faint variations in the threshold, but going over a 55 gallon drum will not damage your hearing. Metal detector headphones showing 1/4" 90 degree jack, coiled cord, padded muffs, and dual volume controls 4. How well do the phones exclude outside noises? Normally, get a set of headphones that will exclude outside noises like running water, wind in the trees, or anything else that might distract you from the detector sounds. Sometimes it may be advantageous to use phones that let you hear outside noises, like in bear or snake country. Or maybe in real hot climates bulky units get too warm. But from a pure detecting standpoint sound excluding headphones are best. Earbuds are perfectly acceptable however for quieter locations. 5. How well do the headphones fit and feel? Imagine they are going to be on your head for 12 hours. Something that feels good initially can feel pretty bad in a few hours. Beware of headphones that are too tight or that have too little padding. I prefer phones that completely cover my ear and seal to the side of my head. I do not like the kind that squash my ear but people's preferences vary. Make sure your headphones are comfortable for long hours of use. 6. How tough do the headphones appear to be? This can be hard to gauge sometimes, but in general avoid anything that looks to have cheap construction. The number one failure point is the cord, so make sure it is strong and well anchored so it cannot pull out. Headphones that feature a 90 degree plug are often desired to reduce strain and prevent the plug from pulling out due to a simple tug on the cord.Some top end models feature replaceable cords so you can carry a spare. I prefer to simply carry a complete spare set of headphones. 7. Finally, be aware that the newest metal detectors are coming equipped with built in wireless headphone capability. Early versions have either been standard Bluetooth, which is too slow, or some faster proprietary method. Standard Bluetooth has a significant lag between detecting a target and the actual audio response heard in the headphone which is bothersome to most people. The problem with proprietary is that you are stuck with very limited options as to headphones. The best option currently for most people is aptX Low Latency (aptX LL) Bluetooth, which is fast enough that most people are satisfied with the speed, and options abound in the choice and style of headphones. To sum up, if buying headphones at Big Box Inc. at the least you'd probably want a set with a stereo/mono switch, 1/4" jack, and volume control/controls just to make sure it will work on most any detector. But remember that headphones are like tires for an expensive sports car. They are one of the only important items on a detector you can customize for optimum performance, the other being search coils. Finding the set of headphones that is just right for you can make a real difference in detecting success, so it deserves some effort in getting the right set. This is where a local dealer with a good selection who is willing to let you try them all out on your detector can really help you out. ~ Steve Herschbach Copyright © 2009 Herschbach Enterprises13 points

-