-

Posts

565 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by PimentoUK

-

It may be worth looking into skateboard bags. Most skaters tend to use 'normal looking' backpacks that have external straps to hold the board. But there are bags that contain the board, and obviously they are long. For some guidance: https://www.ebay.co.uk/itm/391894272614 https://www.dcshoes-uk.co.uk/all-weather-25-l-large-skate-backpack-for-men-ADYBL03004.html https://www.nativeskatestore.co.uk/accessories-c3/skate-backpacks-bags-c28/skateboard-bag-black-p45886 You really need to visit a sports shop in person, preferably with the detector, to truly see the pro's and con's of bags.

-

I have though of another way of doing your 'bush fix' , which involves the use of spring-loaded test probes. These things are used in the electronics industry to make test fixtures for PCB's. There are also smaller variants that are used as connectors in equipment. Three examples: *Some ( older ) cellphones used these probes to make connection to the battery pack. *The charging clip for the XP Deus coil has two of these type probes. *The Equinox USB cable uses them to connect to the control pod port. An example of a manufacturers page: https://test-probe.jp/en/product/battery_contact_and_connectors/spring_connector_pin_&_spring_pin_connector.html and https://test-probe.jp/en/product/normal_probes/ It is possible that one of these probes could be fitted into the coil free socket, so that it presses onto the stub of the broken Pin 5. I have no idea where ( in the USA ) you may be able to obtain such probes easily. If you can obtain a broken Deus coil charging clip, you may have some success in salvaging a pin, though they are one of the main failure points of the clip.

-

I too thought a 'replay' feature had some uses. Some posts of mine on Dankowski's forum in 2014: "Regarding the visual display: I can see some use if you were able to store the previous few seconds of audio data, or raw data. Then if you heard a sound that alerted you, you could grab a trigger-switch, and review what it looked like in a visual perspective. You could replay the audio, too, I guess, so you could determine if it was how you though on the first hearing." ------- "Re-reading the above posts, and when I read my line: "You could replay the audio,.. so you could determine if it sounded how you though on the first hearing" And it occurred to me that replaying in 'slow-motion' might be useful, so you can pick out the details, like the subtleties the original poster mentioned - raspy, clean, clipped, slight iron buzz etc. In principal, if your raw data is stored, then the detector could do a more thorough analysis/processing of the signal before it presents it to your ears at half-speed (or suchlike). In practice, I find it straightforwards enough to just re-sweep / pinpoint etc to get the repeat and home in on the target. But as the implementation of the 'slow-audio-replay' feature is just a button-push, it's not the most far-fetched idea." ------- "I've posted previously about 'capturing' sweep data. Originally, I had thought a 'replay' function would be useful, where the past 5 seconds of data could be re-heard, and perhaps at slow-speed. Then it occurred to me that if the data is already stored, it can be analysed more thoroughly : it's not essential to aim for low latency such as 80 msec; and the peak of the signal can be determined after-the-fact, rather than having to do it real-time. But this can be extended to intentionally storing a slow sweep ( to gather more data ) then analysing it, and re-playing it at 'normal-sweep' rate." -------

-

Anyone Know Were To Get The Kruzer Internal Battery?

PimentoUK replied to kac's topic in Nokta / Makro Metal Detectors

Nice to see that alternative Li cell fitted in OK, good work. Keep the old cell, the protection PCB is re-purposable. Any single unprotected Li cell could be wired up to it, to create a protected one. [ As the Geotech1 Forum is currently accessible, I will promote a thread on it about E-cigarettes/Vape devices, especially disposable types. Useable, fully-rechargeable Li cells can be salvaged from these heavily-littered items.] https://www.geotech1.com/forums/forum/technology/general-electronics/16907-e-cigs-vape-pens-puff-bars-trash-tech -

There's two signals coming from the coil. They are a 'differential pair' , moving opposite to each other. So if a target causes one signal to increase( to a higher voltage ) by 10 millivolts , the other one decreases by 10 millivolts. The control box measures the difference between the two signals. So if one is 'floating' unconnected, it may partially work seeing only one signal.

-

My earlier diagnosis of the pins that failed was wrong, I've corrected the post. It's going to take some work to fix, but parts cost is low.

-

Equinox 6" Coil Connector Repair...Update,Fixed!

PimentoUK replied to microsniper's topic in Minelab Equinox Forum

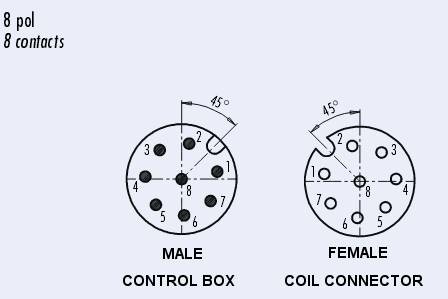

I'll try and get on a better computer tomorrow , and add the necessary wiring info. Update: Attached is a diagram of the connectors, both plug ( control box ) and socket ( end of coil cable ) , showing the pin numbering. The wires connect as below: Pin 1 : TX hot (Shielded wire inner conductor) Pin 2 : TX cold (Shielded wire outer) Pin 3 : Brown Pin 4 : Red Pin 5 : Blue Pin 6 : No connection Pin 7 : Green Pin 8 : Yellow All the small wires are very thin, and may cause reliability issues in the screw-clamp. I recommend you extend these wires by soldering to 10mm length of heavier gauge wire, such as 7 x 0.2mm , applying heatshrink sleeve over the solder joint. -

Equinox 6" Coil Connector Repair...Update,Fixed!

PimentoUK replied to microsniper's topic in Minelab Equinox Forum

Your first place to look for these connectors is eBay.. you may get lucky and find a US supplier, but generally, you're going to find the suppliers are located in places like: "shequxiufenggongyechengA5dongsanloudong 5518000 shenzhen China" Search in the 'Business/industrial' category for: "M12 connector" ; "M12 sensor connector" ; "M12 8 connector" You're wanting the 8 pin socket, straight body, 7mm cable gland hole. These are all quite fat connectors, as they have screw-terminal cable fixings. Finding solder-bucket types is like finding unicorn dung. I have seen connectors with a short 30cm length of cable all ready moulded ... but you don't want their particular choice of wires / shield ( probably some industrial sensor standard? ) , so they are not as good as they may first appear. For guidance, here's some listed on UK eBay: https://www.ebay.co.uk/itm/304622962621 https://www.ebay.co.uk/itm/175222142618 -

My fix costs 20 dollars, gotta be worth a try first.

-

Edited,due to technical errors: Pin 6 ( at 4 o'clock in the above photo ) is not connected, so no need to worry about that one. Pin 5 ( at 6 o'clock ) IS important, it's one of the two signal outputs from the coil. So ... you need to make a connection to pin 5 somehow. Such as soldering a wire onto it. If you can do that, you may as well solder wires onto the remaining 6 pins, and join those wires to a new plug. This presents mechanical issues, like stopping flex/strain on the wires. I'm thinking that bonding some additional plastic pieces onto the rear of the case to support a chassis mount or panel mount plug may be a solution.

-

Is The Mi-6 Pinpointer VLF Or Pulse Induction?

PimentoUK replied to CPT_GhostLight's topic in XP Deus II Forum

Quote: "If the MI-6 works well why does it matter ( if VLF or PI )? " It matters to saltwater hunters. PI machines are pretty insensitive to saltwater, so behave themselves at the beach. VLF's are far more likely to false signal on the sand, making them less appealing tools. -

Anyone Know Were To Get The Kruzer Internal Battery?

PimentoUK replied to kac's topic in Nokta / Makro Metal Detectors

I've edited my post to make it clearer. -

F75 / T2 control boxes are lightweight, smaller electronics PCB's etc are not the way forwards. A lighter shaft would be viable. The lower moulded carbon/resin shaft could be replaced with a woven rod ( like the ML Equinox for example ). The middle section could be thinner gauge tubing ( like the Eqx; 0.040" versus 0.056" ). The upper isn't suitable for thinner tubing, due to dodgy design. The T2 battery is situated where it's doing useful counter-balance work. If it's replaced with a Li cell, it needs to be a similar weight ( 100 grams ) , eg. 3 x 18650 or 2 x 21700. This would give huge run-times, likely 100+ hours, which would be a unique selling point , but not really that useful to most people. ( Sorry for the off-topic )

-

Anyone Know Were To Get The Kruzer Internal Battery?

PimentoUK replied to kac's topic in Nokta / Makro Metal Detectors

Size 904085 means the dimensions are 9.0 x 40 x 85 mm. "90" indicates thickness in tenth of mm, so 9.0mm thick "40" indicates width in mm "85" indicates length in mm So as an 'emergency measure' , you could fit a smaller cell in its place, such as a thinner one, with the same L & W, or one the correct thickness, and width, but shorter in length. Obviously a smaller cell will have a smaller capacity and correspondingly shorter runtime. I've no idea what runtimes on this machine are, so can't say how small you could go and still have a useable machine. Original spec is nominally 3700 mAh I believe? One possible candidate is 804070 size, which appears to be used in some computer gadgetry. I see they are listed on US eBay, US stockist. ( they are 2600 mAh, about 70% of the capacity of the original ) https://www.ebay.com/itm/175146369695 The seller of the above also has a 104080 ( 10 x 40 x 80mm ) , if you think 10mm thick could be squeezed in, it would be a good substitute, as it's 4000 mAh capacity https://www.ebay.com/itm/174763350067 -

Equinox, Vanquish, Xterra Pro (manticore) Coil Hacks?

PimentoUK replied to afreakofnature's topic in Minelab Metal Detectors

It's possible the new XTerra doesn't have a security etc chip inside it at all. That would explain why it can accept V / Eqx coils - it simply doesn't read the chip. And fitting an XTerra coil onto a Vanquish/Eqx won't work because there's no chip to identify it, so it will just result in a CD error and switch-off. -

Equinox, Vanquish, Xterra Pro (manticore) Coil Hacks?

PimentoUK replied to afreakofnature's topic in Minelab Metal Detectors

Yes, I'm familiar with the Ukranian work. They simply took the entire circuit-board from a working Eqx coil, put it in a box, and put a new 'plain' coil on a long cable onto it. There are smarter ways of making a new Eqx coil, but they're not exactly commercially viable, just suitable for the dedicated enthusiasts. The exception is the new Sunray probe for the Eqx. This takes advantage of the fact the original Eqx coil is always still attached, even when the Sunray is the 'working' coil. Hence the security side of things behaves as normal. Geotech1 forum has some chat on the subject of Eqx coils. The original post is about swapping coils about between different machines ( really - putting cheap coils onto expensive machines ) , rather than making new 'cheap' coils for any of the machines. -

Equinox, Vanquish, Xterra Pro (manticore) Coil Hacks?

PimentoUK replied to afreakofnature's topic in Minelab Metal Detectors

Quote:"all these coils are only limited to a chip and not the coil itself" A Chip ? In the Equinox, there's a circuit board full of components, including at least two chips, and plenty of transistors/diodes/R's&C's etc. The 'security/identification/anti-copying' part of the electronics is just a part of it. The main bulk of the electronics is a low-noise pre-amplifier circuit with differential output, to boost the signal levels befor sending it down the cable. There's no compelling reason why new XTerra coils will have too much in common with the other machines. The upper freq limit of the XTerra is 15kHz, the coils may not be capable of running higher, for example. Vanquish/Eqx coils have a transmit-coil made from 'pseudo-Litz' wire ( hundreds of strands of fine-gauge enamelled wire ), to get good high-frequency performance. The New XTerra may just have a single strand wire, for cheapness. The Vanquish and Equinox do have a lot in common, though the Vanquish looks to have a simpler pre-amp, probably not such a low-noise design as the Eqx. The security etc etc chip may be the same basic part ( a serial-access memory device ), but will no doubt be programmed-up to identify as 'Vanquish Only' instead of 'Equinox Only' , to stop people hacking V coils onto the Eqx ( of all the 'hacks' , this one is the most plausible ). The Mandingo's coil is almost certain to have an inertial sensor ( accelerometer or rate gyro ) inside it, much like the CTX coil. This then more-or-less means a microcontroller chip too, for serial data communication. It's a different animal entirely, so there's no way a Vanquish/Eqx coil will work on the Mandingo. -

I'm also wondering what "All metal mode" on the Mandingo means .. Zero disc? Prospecting mode?

- 42 replies

-

- fisher detector

- manticore

-

(and 1 more)

Tagged with:

-

This topic was covered somewhat in the 'Sea Ghost' aftermarket Eqx case thread. It has a 3D-printed case, with all the buttons on the front panel. And also here: https://www.detectorprospector.com/forums/topic/14071-why-didnt-minelab-think-about-it/ I think 'side buttons' have their place. I personally don't want the backlight button anywhere it can be inadvertently pressed. If I'm detecting 'low key' at night, a 'flashlight incident' is not OK. I think the 'Power On/Off' button may benefit from being a 'Proper' switch for electrical reasons (eg. zero ON resistance ). Membrane / carbon spot / rubbery type buttons are fine for data being read by microprocessors.

-

Hmm, I suppose when I said "Equals it ..", I really meant: "Has sufficiently low latency that it's not really noticeable to most people in a detecting scenario, hence it's comparable to WiStream" WiStream may be 20msec, BT-LE may be 30msec, but you would be hard pressed to tell. After all, [i]most[/i] detectors have over 70msec latency, and you get used to that. [ Tek T2 / Fisher F75 stated as 78msec lag in normal detecting modes, I'm unsure about the newer FA (fast) mode ] Edit: Here's a photo of the Eqx 800 PCB: the two completely seperate wireless systems are at the top edge of the PCB ( with the chamfered corners ). The black squares are the RF chips, there's a seperate quartz crystal oscillator module for each chip, a fair pile of R's and C's on top and bottom of the board. They couple together into one antenna, along the edge of the board. ( these are the official EMC test lab photos ) https://md-hunter.com/wp-content/uploads/2017/11/opening-the-minelab-equinox-800-600-03.jpg

-

I know electronics is my area of expertise, but I've no idea how much the wireless chip, it's associated peripheral bits, and the cost of placing them on the board would cost. Then there's the extra PCB area - this costs too, and makes the machine bigger. Not forgetting the pile of software that the main brains has to run in order to control the WiStream link; remove that, and the designers have a load of free program memory, that could be used to add functionality to the detector.

-

Don't forget that adding WM08 compatibility would add to the detector price. Having a second set of wireless transmitter electronics for the Wi-Stream system is supposedly not needed, as the Bluetooth LE specification equals it, in terms of latency, anyway.

-

Are 900 Shafts Available And Compatible For My 800?

PimentoUK replied to ChuckScrivener's topic in Minelab Equinox Forum

They are not at all compatible, unfortunately. However, you may find my Equinox Compact Shaft project gives you some ideas: https://www.detectorprospector.com/forums/topic/14805-my-compact-eqx-shaft-project/ -

They are quite commonplace, the low cost has resulted in them being fitted into all manner of gadgets. For example the hand-controllers for Nintendo WII games machines. Simple remote-controlled helicopters / drones use them to maintain level flight, or to stabilise the direction the heli is pointing (yaw control) . Modern cellphones have a load of these sensors in them. Hard-disk makers use them to detect the 'dropped laptop' problem, parking the heads quickly before impact. Image stabilisation of video cameras / camcorders was an early common application in commercial products - the sensors measure the shake/movement of the camera, and the data that is read from the CCD sensor is manipulated accordingly. https://uk.farnell.com/w/c/semiconductors-ics/ic-sensors/mems-accelerometers?range=inc-in-stock&sort=P_PRICE

-

Putting rate gyro's / accelerometers in a coil is nothing new, the CTX3030 has one, I'm sure the Manticore will have one. They are very cheap, sub 2 Dollars for a lower spec one. Detectors use band-pass filters to help seperate the 'target signal' from the 'target plus ground signal' . Think of a hifi graphic equalizer with '330Hz' set to maximum, all the other sliders set to minimum. In the case of a metal detector, the target 'pops-up and disappears' at a predictable rate as you sweep over it. Using a band-pass filter centred on about 10Hz is roughly what works best for a typical sweep speed. But if your swing is slower, a lower freq band-pass filter would be better. What an inertial sensor like a rate gyro can do, is let the microprocessor brains know how slow/fast your swing is, and automatically optimise the band-pass filtering continuously, to cater for swing-speed variation. Other uses include: The CTX3030 has a display mode that shows multiple targets in a line on screen. It needs to know which direction you are sweeping, so it displays the left-to-right correctly. At the end of every sweep, you reverse coil direction. Sometimes this can cause a false signal. If your machine knew you were reversing sweep direction, it could momentarily reduce sensitivity, giving no falses. Ground signal pickup obviously varies with coil height - if you coil is 6 inches above the ground, your coil is clearly going to see a lower ground signal. An inertial sensor could in theory measure the up/down wobbles of the coil, and use this to compensate for the (probably) matching ground signal changes. This could help give a more stable auto-ground-tracking function. Or it could reduce ground-signal falses, possibly increasing depth slightly, though use of multi-freq is the primary depth-enhancer, other techniques are just 'fine-tuning' .