Sun-Boy

Full Member-

Posts

16 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by Sun-Boy

-

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Hi Erik, Thanks for the input, reducing the frequency to 15kHz won't be a problem, running dual frequency is also an option, the original system I worked on eons ago was running at 3kHz. This revision is pretty well set unless I cut up the pcb, which I don't want to do right now. I'm a builder designer and my actual in the wild detecting is limited to near nothing. This design is based on a system I worked on many years ago, its going to be fun seeing how it performs. I'm in South Texas, so I'm going to see if I can get some locals in San Antonio to test it out and give feedback. -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Hi Folks, Well...life, work, and health happened and I had to put the detector on hold, but I'm getting back to it. I got new boards and components on order, as well as a few mechanical parts. I'm sticking to the all analog design for now, but have a recently retired embedded programmer friend whose interested in helping out, my programming skills are basic at best. I'll update the thread as I progress through the design. -S -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Litz wire is a good choice, I'll try some experiments with it in the future, for now I'm winding them with regular magnet wire - do you have a good source for Litz wire? About the 60KHz, I came to that frequency through testing, I tested my system with multiple frequencies and found that gold worked best right at 60KHz , and that iron, silver, nickle, etc., worked well with either low or high frequencies - and if the detector can't see gold, well, it really has to find gold . -

Kac, I was wondering if you could add another part to your test. Could you take a silver quarter, and measure the VDI at different depths? Like at 2.5", 5", 7.5", with the quarter in the same orientation, I'm curious to see if the VDI changes with distance on the same target. -S

-

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Hi Kac, There is a little "something" happening in my custom coil that I can't replicate with an off the shelf one, I may experiment with some in the future, but for now I need to use my wiring configuration for my system to work properly. -S -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

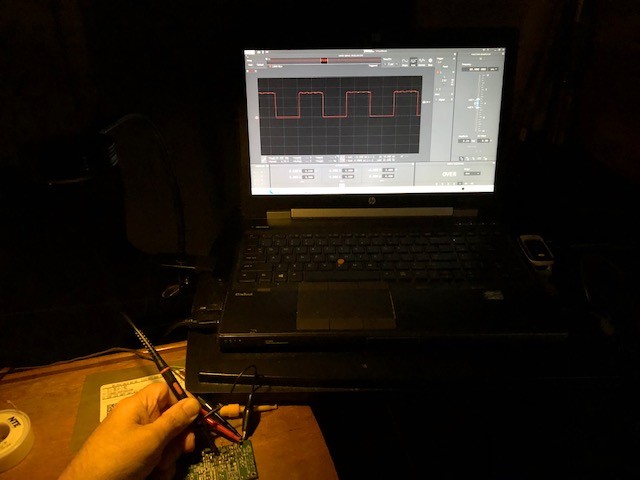

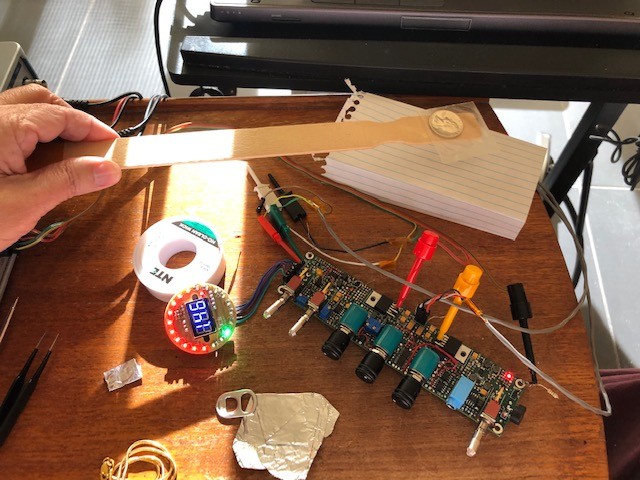

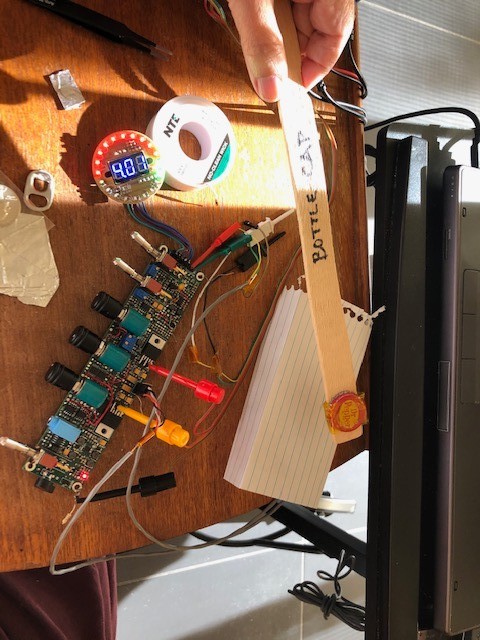

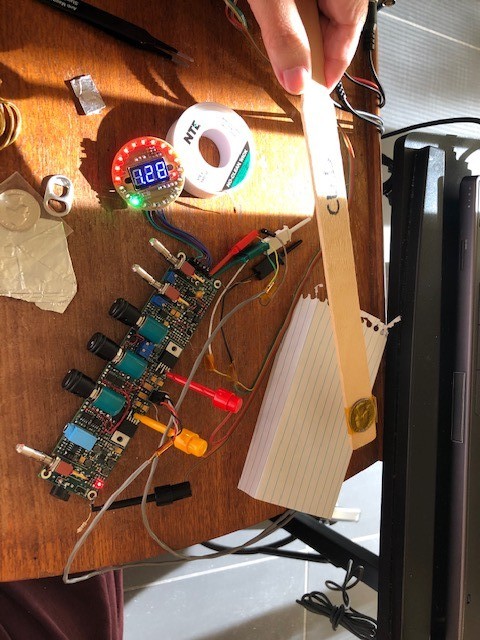

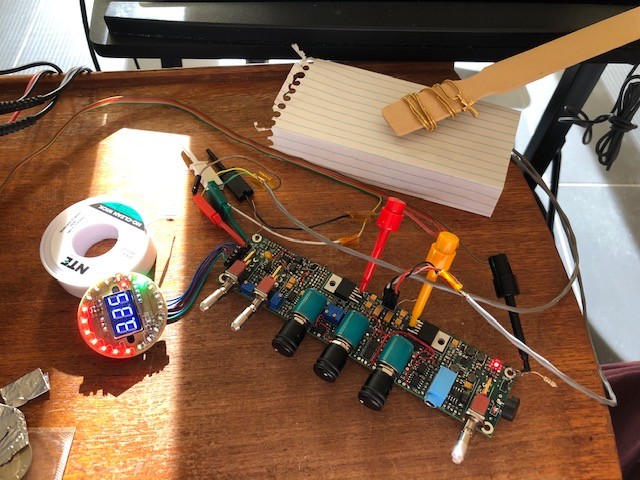

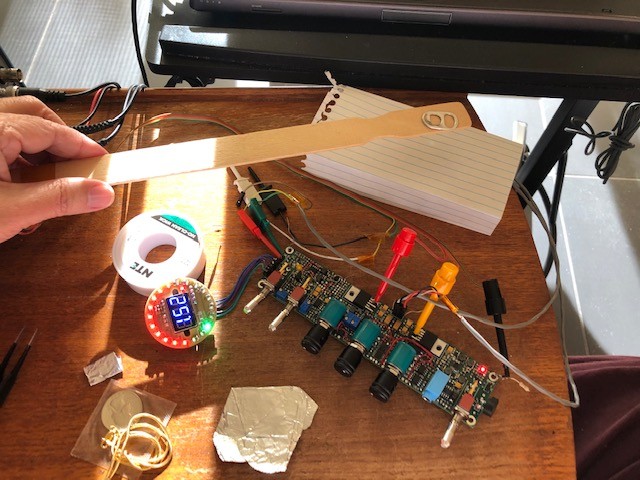

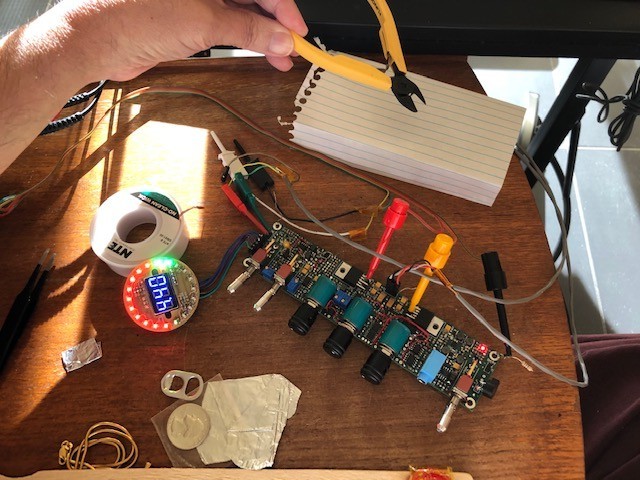

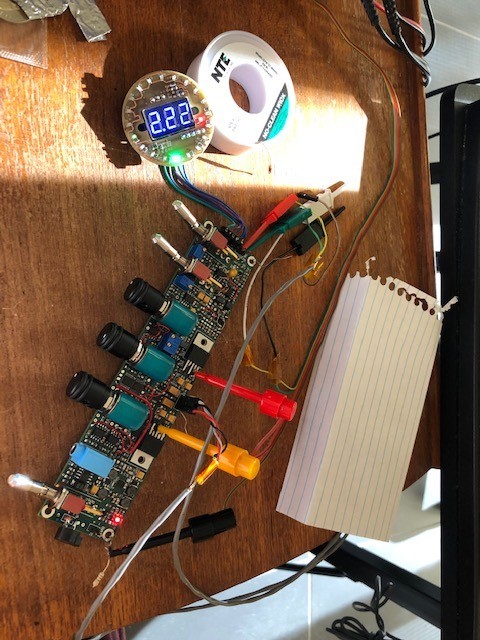

....so, when we last left our hero's....we were giving a rundown of some mechanical hardware which I proceeded to put in boxes on my kitchen table.....and not touch since then.... But , I did do some parts soldering on the new board today......only to find out that I'm not as good as I used to be when it comes to putting down LLC packages, (sigh), it was the heart of the power supply. So I decided to put that aside for now and moved on to populating the oscillator, it's a pierce crystal oscillator running at 120KHz, it's then divided down to 60KHz, this is going to be my operating frequency. I also use the divider to give me a good 50 50 duty cycle. It gave me some trouble before I got it running. but it's looking good now. I'm using an older NI Virtual Bench on my laptop for the bench testing/troubleshooting. Sorry for the dark photo, I may replace it later. I experimented with manually placing solderpaste on the board to place the LLC package and only proceeded to make a mess. It's the only one on the board, so I'll just have to wrestle it down. -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Thanks Mike, For now I'm only making one, and until I get the coil wound and do some real world testing I'm not sure if it's worth seriously pursuing. I'm a builder/designer, I've worked with magnetic's instruments in the past that gave me the foundation for what I'm doing here. I know the old revision will discriminate well, but I've made some updates to the new revision that are meant to improve the design, hope it works. About the two tone option for ferrous and non ferrous material, I have my design set up to do something similar to that, when I get further down the road I'll be able to elaborate on this feature. A quick question: When I see guys using their machines, they have to be swinging in order to get a signal, is this the case with most VLF detectors? Can you guys give me a quick rundown on some of the machines and how they detect? I ask this because I've set up my machine in a configuration where you don't have to swing to get a signal, it's in constant search mode, kind of like the machines that have the pinpoint mode. -S -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Tom is it tricky to register at the forum? I'm having some trouble. -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

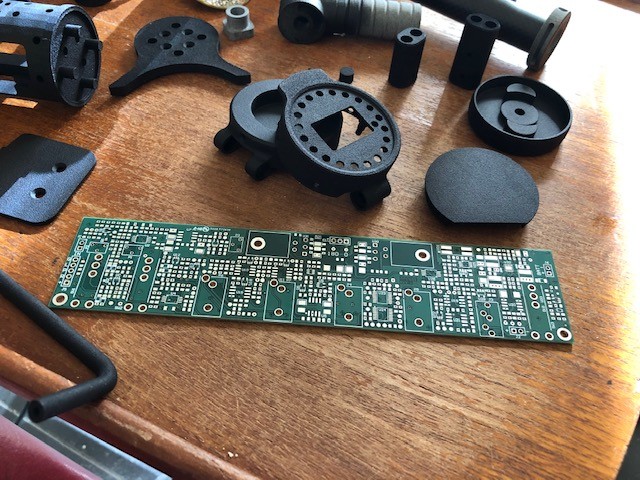

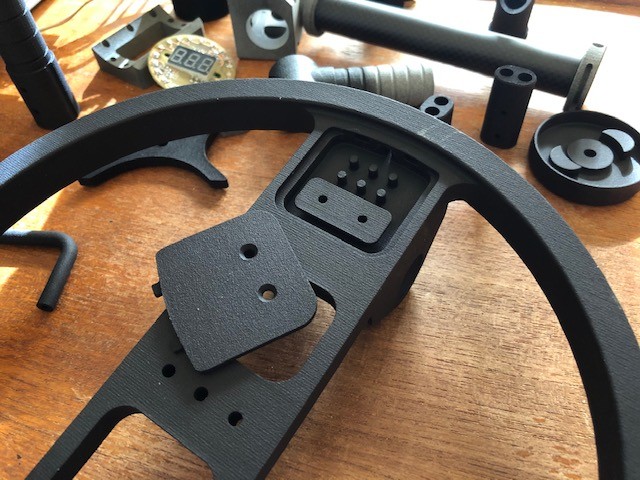

Getting some parts in: Display housing, main pcb and other miscellaneous parts. Display housing parts and display pcb Display board in housing Internal frame to hold pcb, batteries, and other connectors Inserted into the carbon fiber housing, with front feet attached Display frame laying on top of the main tube housing Coil form Wire attachment area and cover Spent some time today cutting carbon fiber tube, doing a little spray painting, nothing major. I'm not looking forward to cutting out the openings on the tubing without a decent mill or cutting tool, only two of the drilled holes will be showing, everything else will be covered by frames, so no jagged holes will be showing - but this stuff isn't the easiest material to work with. About Carl and George's Geotech1 Forum, is it on this forum somewhere? I would like to check it out. ...we'll see if I'm able to get anything done tomorrow... -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Yeah Joe, I've been dabbling with the design for several years, it's just now gotten to this point, you know, life happens, you step away from it, may not get back to it for months or years. I can't do everything else I used to, but this thankfully is keeping my brain busy. And I'm surprised how light the parts are coming out, aluminum is really pretty, and I wanted to go with it, but the price is just to high. I haven't used Shapeways, but I'll definitely look into them and get a quote on my next parts. Yeah I used 3d Hubs when it was folks in there garages and you didn't always get what you were expecting, but I knew that going in, so I would take my warped coil forms and do my best with them, lol. I'm not interested in 3d printing enough to buy one, I know me, I'll do a few prints and then the machine will sit idle, better to send out for my parts. I've gotten my mechanical parts in for the housings, and interconnects, as well as the new main electronics pcb, I'll update the thread later tonight with some new pic's. Still waiting on my components from Digikey, and then the soldering begins again. A buddy of mine who is a software guy, really expert with embedded micro's dropped by yesterday, he wanted to see how it was going. I walked him through the design, and he gave some idea's, I was amazed at how well the unit would see his gold wedding band. ...so it continues, hope to upload some pic's tonight... -

New Prototype Detector - My First Analog Attempt

Sun-Boy replied to Sun-Boy's topic in Metal Detector Advice & Comparisons

Hi Guys, in answer to the questions: Kac, LCD instead of Led's is an option, but that would mean interfacing to a screen which would mean a micro and programming which I'm not good at, so for now I'm stuck with led's Coil mounting in the center, yep, that was how I designed my original one, but I wanted to keep the wiring short to the coil windings, but I do prefer the center mount one for the reasons you mentioned, I like the center mount for the next iteration. I'm not real clear on the dual circuit you mentioned, not to sure what you mean. I'm not sure why I didn't go with a pot for gain control, I think I didn't want the coil balance and gain to interact, but it's an option to explore. Joe, Aluminum parts would be great, but when the money comes out of your pocket....eh....time for rapid prototyping. I use a place called 3D Hubs, I had them use MJF, Multi Jet Fusion, the parts are amazingly close to actual dimensions, probably +/- 2mils, they do a great job and a excellent prices. The Cuff is an anderson labs, really good quality. The Coil wire is running down the center of the shaft. Waterproof? Nope, it will be splash proof at best. Single Freq. VLF, I would say it's kind of a hybrid VLF/CW - continuous wave, you don't have to swing the coil to get a signal. Battery cover is on the back. Batteries are 8 AA's, typical black plastic holder. Battery life right now I think will be between 15 and 20 hours. Led's are a little inset right now. Materials I'm using on this model are carbon fiber tubes for all the shafts as well as the electronics/battery housing, if it don't work, it will be the prettiest non performing metal detector made! :) GB, I hear you, get it working now and make it pretty later....but I can't help it!!! :), gotta make it pretty..it's just how i"m wired :). And thanks for the zip lock plastic soil idea, that will work well. Johnny, I will do some testing over the holiday weekend with some rusty nails, straight and bent, and I think I can find some rusty tin. I'm still not to clear on the dual audio. Thanks for the input guys, this model is pretty much set, but we improve as we go. -S -

Hi Folks, Thought I would start a thread showing my first attempt at an analog detector, I've been working in the electronics field for many years mostly in the analog/rf area. Hope everyone enjoys the process, and any input or suggestions would be appreciated. I'll try and post as I go along, but this is my after hours hobby, so updates may come every few weeks. I apologize if this goes overboard on the images. So here goes..... Here is the overall unit, the display will tip up and turn on. Closeup of the display Display tipped up, it will show RSSI across the top, and material ID in the center and across the bottom. Control Panel, has gain hi lo, discrimination on off, coil balance, threshold, volume, phone jack, and on off with lo bat indicator. Coil Actual board and display turned on and balanced, I'm sorry for the vertical image I couldn't straighten it up, the coil is under the paper, it's a hand wound 3" OD test coil. Note that this board has only three adjustments and the one in the above renderings has four, this one has no threshold adjust. 1957 silver quarter Gold chain and cross. Aluminum pull tab. Coke bottle cap. Clad quarter. My steel cutters. I'm getting parts in to start putting the new one together, hopefully my updates to the circuit will work out. We have a saying, "may have to shoot the engineer to finish the project", it feels like every other day I come up with another improvement :), anyway I hope you guys enjoy this, I'll post as I go along. -Sun-Boy

-

Thanks Joe, No I haven't toured the Garrett facility, it's in Dallas and I'm in San Antonio, that's a long haul. No I'm not an engineer, I'm an electronics tech, I've been in R&D for over 30 years, started as a bench tech building and troubleshooting analog and rf custom equipment. I dabble with microcontrollers, but It's not what I'm best at, so my first system is analog, my next one will be based on an ARM Processor. But back in the day the tech's did it all, the board design, the assembly, etc., and I got to work with some exceptional engineers. Now I mostly do board design and mechanical design, using Altium Designer for pcb, and Solidworks for the mechanical. Building electronics is my hobby, and I have some magnetics experience. What really prompted me to develop a serious machine was seeing a lot of YouTube guys struggling with discrimination, especially gold and aluminum. I'm probably going to start a thread and show my current design, I'm a little hesitant, (what if it ends up being junk, lol). I'll try and talk myself into it, I can't show schematics but I think the boards and the mechanical will be fun for folks to see. -S PS: And it's really neat that Carl M. owns this forum.

-

Thanks for the welcome Pop, I would love to hunt, I know of several places where I could get permission where there is silver, but having some physical problems limits what I can do. So, being a tech I thought I would do the next best thing, (and it's fun), that's design up some cool detectors. -S

-

Hi Folks, I'm developing a new VLF analog prototype detector and am using a concentric coil I've seen in the book "Inside the Metal Detector", it has the TX coil in the center with upper and lower RX coils that are balanced. So I have some questions for you experienced folks: Does anyone know if this style of coil is still used? If not, does anyone know why it fell out of favor? Any pro's and con's? Thanks for your help, I'm considering showing some of the pic's as I progress, I have the next revision pcb on order, we'll see how it goes.

-

So a big hello to everyone. I'm really new to all this, and have yet to do any detecting, I'm more into designing detectors than using them. I'm hoping to get feedback from the users here to help me refine my designs, I think I can develop some really useful and fun machines. I'm currently working on my first analog prototype, to be followed by a microprocessor controlled one. I'm integrating some features that I think are missing in most if not all the current designs, and am looking forward to hearing all your feedback, what you like, what you don't, what you can do without, etc. Don't know how often I'll be here, but I'll try to add to the conversation in a positive way when I am. Thanks folks, -SS