Search the Community

Showing results for tags 'company news'.

-

I ordered a 5.3 "/ 15cm / concentric coil for Tesoro Mojave .. ,, in my opinion there are not many of these coils for sale ... so I said to myself .... I will buy it now or never ... I believe that this coil will not disappoint me ...

-

-

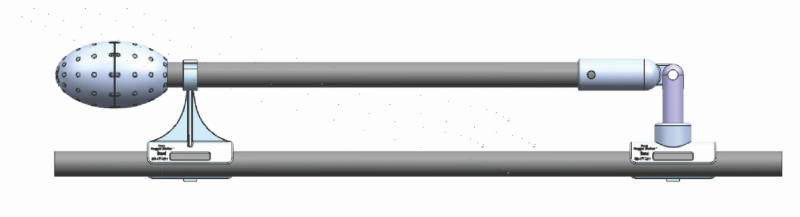

Gang the first production prototypes of the SAGA V2 Swing Assist Guide Arms are here. See what improvements have been made. Comments welcome. Thank you to the people that gave me feedback on the first version which as we all know was a crash and burn. -Doc

-

Hi, all! I just wanted to mention that in the spirit of the Holidays, Steve's Detector Rods will be giving away one carbon-fiber complete Equinox shaft (upper shaft and lower rod), AND one carbon-fiber Equinox lower rod, to two lucky U.S. winners. Two separate drawings will be held on Dec. 18, one for the complete shaft, and a second for the lower rod. Entry into the drawings is completely free, with no purchase required -- and the entry period is open from now, through 11:59 PM on Sunday, Dec. 15. Additionally, ALL entrants into either drawing will qualify to receive 10% off of any item purchased through Steve's, for the entire month of December. For additional information, including details and eligibility, please visit Steve's Facebook page, at https://www.facebook.com/stevesdetectorrods Thanks! Steve

-

I bought an sdc and have about 1.5-2 months before I can bust her out. I wanted to give Rob A. @ Rob's Detectors a plug because of the great service and what I believe to be an exceptional deal he offered up!!! Thanks again Rob and I can't wait to get out with the new weapon....

-

So here's the latest SAGA (Swing Assist Guide Arm) news. As someone mentioned, maybe SAGA was not a good name as the development of this product has become something of a SAGA. The initial test run of 50, we took some and put them into the field. MONUMENTAL FAIL. These things were falling apart faster than you could swing your detector. To say they were under-engineered was putting it lightly. I had the basic concept of how this should be designed, but ultimately I depend on my fabricators to use the right material and finally design the product to withstand the rigors of metal detecting. Literally the only thing that performed well was the handle and the storage clip. I was shocked because I have been using the same company for 25 years and they have never let me down. And considering that they are working to totally re-design the piece, they didn't let me down this time either, it's just that it is taking a lot of time to make sure we get it right. The straps were totally worthless. If you pulled on them, with very little force, they broke. We are now making the straps of super rubber. The pivot joint, was made too weak. Various pieces were just snapping. The pivot pin was either falling out of the joint or simply breaking. The ball joint which I thought would be a great idea, was actually a pitiful execution. It actually allowed too much play in the joint and made it feel like you had little to no control over the Swing Arm. Precisely what I did not want to happen. There were only really two movements I wanted. Obviously the first, a pivot joint that would allow you to move the Swing Arm out and away from the detector, to the right or left depending on which side you mounted the SAGA on. The second movement was a rotation joint allowing up or down movement to prevent breaking the pivot joint. Literally every Swing Arm out there has the ability to move out and away from the machine by some method that is not a true pivot joint, and designed with some very minor collateral allowance of up or down motion, but this limited range of motion causes a lot of breakage of the competitor's fake pivot joints. After going through the process I now know why competitors have designed their fake pivot joints in this manner, because they only needed one mold, which lowers costs significantly. My design requires 4 different parts and 4 molds. That does not count the 5th mold for the rod storage clip which my competitors do not offer. In addition to which competitors Swing Arms will not work on all detectors. The shafts on detectors have started to come in all shapes and sizes making it difficult to design a mount that will fit them all. I think I have accomplished that feat. The swivel joint and storage clip can be mounted on a variety of different rod sizes and shapes. I could only laugh at what an absolute failure this thing was. If it had been one little thing that was wrong, then I would have been mad, but when the entire damn thing is an abortion, well all you can do is laugh and say let's go back to the drawing board. Literally, until the Corona Virus came along, this Swing Assist Guide Arm was the worst thing to ever come out of China. To save time I went to a local tooling shop with my new plans on how to make this thing bullet proof. I am happy to report that the resulting prototype is strong like a bull, and extremely sturdy. It is in the hands of my factory in China and they have already done the CAD renderings. This one (SAGA Version 2.0) will be a winner! -Doc

-

I reached out to Jimmy through his website for Discovery Tours. http://discoverytours.us/ Here was his response: Hi Walter, We are still doing our Discovery Tours to England. In fact this was our 29th consecutive Year .I have personally missed participating in the tours for the past 4 years for "health issues" ....I turned 89 years old this year, but I hope to make at least one more trip if I can get a better handle on health. Meanwhile, I do all the paperwork from here. Get the participants, collect the funds, keep all informed of details and handle the return of the finds to the participants when I get them back from David and Trish in UK. So the only difference is that I don't get to participate in England. I hope to make one more trip at some point when health improves....but age is not on my side, sorry to say. Our website is still active and David and Trish keep it up to date with pics and finds and info, as always. If you are interested in a future trip.........let me know and I will keep you on my mailing list. Best regards, Jimmy Thanks! Walt

-

From the Codan news release at http://www.codan.com.au/Portals/0/investorpubs/22 AXS Announcement - Minelab awarded $6.7m contract.pdf (copy below): "Cooperating with NIITEK Inc., the HDD will combine Minelab’s new Multiple Frequency Continuous Wave metal detection technology and NIITEK’s advanced ground penetrating radar." 31 August 2016 MINELAB AWARDED CONTRACT TO DEVELOP NEW HANDHELD DEVICE DETECTOR FOR THE AUSTRALIAN DEFENCE FORCE Minelab Electronics, a wholly owned subsidiary of Codan Limited, has been awarded a $6.7m contract by the Department of Defence to develop a new Handheld Device Detector (HDD). The funding received under this contract is to further develop a dual sensor metal detector which incorporates ground penetrating radar. It will partially offset the development costs of the product, and the project is expected to be completed by 2018. The development of the HDD builds on Minelab's success in technology development and product innovation for use in military programmes. Codan is particularly pleased to be of service to the ADF and to provide an enhanced capability that currently does not exist. Once the HDD enters into service with the ADF, we are confident that other militaries will seek the same level of capability, broadening our market for countermine products. The contract supports Codan's stated strategy of growing its profitability by improving and broadening our product offerings while ensuring our value propositions remain relevant and leading-edge. Previous to this award, in March 2014, Minelab was selected by the Department of Defence's Rapid Prototype Development and Evaluation (RPDE) programme to receive $1.0m in funding to further integrate metal detection and ground penetration radar technologies into a lightweight and compact mechanical platform. In December 2014, RPDE provided an additional $1.3m in funding, and Minelab subsequently produced an advanced prototype of the HDD. Cooperating with NIITEK Inc., the HDD will combine Minelab's new Multiple Frequency Continuous Wave metal detection technology and NIITEK's advanced ground penetrating radar. The HDD was designed taking into account the comprehensive requirements of the ADF, supplemented with feedback from Army User Groups. It will include advanced detection technologies as well as new standards of compactness and ergonomics. On behalf of the Board Michael Barton Company Secretary MORE INFORMATION ON THE NIITEK/MINELAB GROUNDSHARK Minelab Mineshark

-

With 2019 in the rear view mirror what will 2020 bring? Multi Frequency? Pulse Induction? One thing is for sure, this company is going places fast!

-

I was gone part of the morning but when I got home it was a pleasant surprise at my door. My I believe new Simplex was waiting for me. It came on a two day priority mail that I believe that Dilek had something to do with. It came back double boxed like I sent it . Life is great when you’re dealing with great people and a great company. You know up front who you want to spend your money with. Dilek I sent you a personal message but let me say it again. Thank you so much ! Chuck

-

Minelab decided to emulate Garrett and put together their own group of social media “stars” called the Detexperts. I thought it was a good idea since social media is where most of the action is these days. I am not talking just Facebook, but also YouTube, Instagram, etc. The thing is I figured when Vanquish hit the streets we would see all sorts of activity from the Detexperts, and there has been nothing. Zilch. I would have thought Minelab would send them all a Vanquish or something to roll out a social media blitz. Ironically it is people who jumped on the early buy at Dick’s Sporting Goods that are posting all the videos. I have to admit I am puzzled by Minelab’s marketing at times and can’t really figure out what the whole Detexpert thing was all about. It seems like something they just started and then promptly forgot about. Maybe they just wanted to hand out a few free t-shirts and that was it.

-

Hey Gang, Well, back to the drawing board. The first samples of Swing Arms we got into the field have failed miserably. Thanks to all of you who have put up with the frustration of being guinea pigs. If you have had one that failed, return to the dealer and he will refund your money, until the revised version is available. If you have one that has not failed, use it until it does, so you can give us feedback on what happened. Pictures are very helpful. So some of the things that have been identified are: 1. The strap, which I requested be made with some kind of UV rubber with fiber reinforcement was not made with reinforcement, so it stretches and then breaks. It also needs to be about 1 1/2 inches longer with one more adjustment hole. 2. The pivot ball joint has way too much play in it. It should only rotate 360 degrees with no side to side movement. Initially I thought it would give more freedom of movement, but it is movement that is not necessary and causes undo stress on the joint and a feeling of instability. The purpose of the ball joint is to only allow the arm to move up and down so it does not break. But the opposite is happening, because it has so much movement, there is a lot of stress on the part. That is an easy fix, the collar has to be redesigned to restrict the movement. I'll try to attach a pdf file to show you what I am talking about. Collar correction.pdf 3. The pivot joint, the one that has a pin in it that allows the Swing Arm to swing out and away from the detector is too thin and flimsy. This was supposed to be made of Nyglass, but I think they used something that was not suitable for this part. This will have to be redesigned to be thicker with tougher material and a more substantial nylon pin that will be sonic welded into place. The concept and functionality is solid, it is just the materials and some of the design that needs to be corrected. Now I don't know many manufacturers that announce to the public that they "screwed the pooch" so to speak. But you guys have always been very helpful with ideas and suggestions and helping me field test all this crazy stuff I come up with. So I wanted to include you on this. And trust me, this is the process I go through every time with everything I develop. From initial concept, to design to prototype to pre-production to testing to modification and back to testing and then to full production and shipping and delivery and to the market runs about 9 months to 1 year. Sometimes things go very smoothly, sometimes, not so much. It depends on the complexity of the item. Unfortunately for this SAGA swing arm there are so many different molded moving parts. 2 Molds for the handle, a mold for the storage clip, 3 molds for the pivot and pivot ball joint assembly, 1 mold for the straps, a mold for the buttons in the fiberglass rod, extrusion mold for the fiberglass rods. About $10,000 in mold costs alone. Fun, right? However, I have never brought to market anything that I don't use myself and stand behind 100% And the SAGA Swing Assist Guide Arm will be no different. So your patience is appreciated as we work on SAGA™ Version 2.0 Speaking of production, the "G Spot" scoops are in production but I had them made with a satin finish as in the attached picture. The shiny ABS material caused too much glare in my opinion and was too slick allowing small gold to slide too easily. The top picture is the new satin finish and the bottom scoop was the shiny prototype. Standby while we work out the bugs. Thank you and Happy New Year. Doc

-

Why, why, why? People ask why. Why did they do that? Why don't they do this? Well, here is some explanation via Dave Johnson of First Texas posted in 2009. To quote specifically "Sometimes forum denizens claim we do this or that for some particular reason, when in fact they know nothing of our reasons. And then there's posts which demand that we say why we do this or that. We don't sell "whys", and therefore don't publish very much information about them." FISHER, BOUNTY HUNTER, AND TEKNETICS: SETTING THE RECORD REASONABLY STRAIGHT 5 Feb 2009 Dave Johnson Chief Designer, Fisher Research Labs & First Texas Products There's been a lot of nonsense posted on the forums about the relationship between Fisher, Bounty Hunter, and Teknetics. The nonsense doesn't seem to be getting cleared up through normal forum self-discipline, so I've decided to intervene with information from "the factory". Fisher and BH/Tek (First Texas Products) are two separate business units which operate under the same roof and utilize mostly the same people. The product history of these two business units is different. The present Bounty Hunter and related products mostly evolved from George Payne's designs of the 1980's. During the 1990's under a different company, the BH trademark earned a reputation for terrible quality. First Texas Products purchased the BH line in 1999 and got to work improving the manufacturing operations. After Dave Johnson came on board in 2003, the products were completely redesigned inside for improved performance and reliability, even though most were unchanged externally. Bounty Hunter is now, and has been for years, a quality product which offers excellent value. And if you trace out the circuit of (for instance) the venerable Quick Draw II or Time Ranger, you'll still see the "Payne target ID circuit" which was at the heart of the original Teknetics. The Teknetics T2 introduced in 2006 was a totally new metal detector from the ground up, not based on any earlier design. The senior designer was Dave Johnson, and John Gardiner wrote the software. We called it Teknetics because we owned the trademark and because the goal was to be on the leading edge of metal detector technology and performance, just as it was with the original Teknetics. Dave Johnson was the senior electronics engineer for Fisher (in California) from 1981 to 1995. Of the legacy Fisher products we still manufacture, most are Johnson designs. In 2006 the investment group here in El Paso bought Fisher from its parent company COHU, and moved operations to El Paso. Since that time we have introduced several new Fisher products. The F75 & F70 were major revisions of the T2 platform. The F4 & F2 are major revisions of a BH type platform which is a modern descendant of the original Teknetics designed by Payne. On these new products, Dave was the chief designer and John wrote most of the software. Nothing to be ashamed of there! For several years we've had under development a totally new platform for use in products which don't have to push the extreme leading edge of performance. That platform was first brought into production as the BH Gold and Platinum. With major revisions it became the Fisher F5, and with further revisions the platform became the Teknetics Delta, Gamma, and Omega. Dave was the chief designer for all these products, but most of the actual development work was done by Jorge Anton Saad with assistance from other engineers. SUMMARIZING: back in the Stone Age, Bounty Hunter, Teknetics, and Fisher were completely different products from unrelated companies. In 2009, these are brand names of mixed ancestry which became relatives through acquisition. Within the present extended family, there are several different basic platforms, and more platforms are under development. In the Fisher line, there is continuity of design engineering going all the way back to 1981. DO WE EVER MAKE MISTAKES? Yep. In the last several years we've come out with more new products than the rest of the industry put together. If we had done nothing, we'd be out of business, but at least we wouldn't have made any mistakes along the way! WHERE ARE OUR METAL DETECTORS MADE? Almost without exception, our metal detectors are manufactured in the United States. Most of our circuit assembly is done in Juarez just across the river, in plants just as modern as you'd expect to find in the USA. Several legacy Fisher models were manufactured in the Orient rather than in California: new Fisher management terminated that arrangement. One high volume low end BH platform series of products is manufactured both in the USA and overseas, giving us some flexibility on that particular platform. NOW, ABOUT THAT NONSENSE: Here's a brief sampling of the sort of malarkey that I occasionally see posted in forums. Some of this is so outright stupid you might think I'm making it up. Nope, I've seen all this on the forums, and lots else besides. "Bounty Hunter is cheap junk." .....(was true a few years ago, but no more) "BH bought Fisher in order to run it into the ground." .....(with Dave J. as the chief designer? Get serious!) "The new Fishers and Teknetics are just rebadged Bounty Hunters." .....(hasn't happened yet, but if it does it's a good thing, not a bad thing) "The new Fishers and Teknetics are made with the same parts as the BH's, so it's all junk." ......(we buy the same high quality electronic components that everyone else does) "The new Fishers aren't 'real Fishers' ". ......(being new makes things not real?) "They're all made in China, that's why they're junk." ......(made in China = junk? Where do you think most electronic stuff is made these days?) "They're all made in Mexico in chicken-shed maquiladoras." ......(nope, someone's imagination is 'way too vivid) "They cut costs by hiring a bunch of illegal aliens." .....(why bother? There are plenty of people here legally, experienced in the electronics industry, and willing to work) "The person I talked to on the phone had a Mexican accent, must be stupid." .....(smarter than you think, and speaks better Spanish than you do, too) "The 'old Fisher' did everything right, now look what happened!" ......(the "old Fisher" was a basket case, that's why COHU got rid of it) There are sometimes posts about new products by people who hardly know anything, and are mostly just making up a bunch of stuff. Sometimes forum denizens claim we do this or that for some particular reason, when in fact they know nothing of our reasons. And then there's posts which demand that we say why we do this or that. We don't sell "whys", and therefore don't publish very much information about them. We sell metal detectors and do publish information about them. There have been posts by people who were happy with their machine until we came out with an improved version, and then they're mad at us….. gee, if they want a metal detector with a guarantee that the company which manufactured it won't ever come out with anything new or improved, we're definitely the wrong company! They need to buy a Compass on Ebay, then they're safe. A forum is place of discussion and disagreement, sometimes vigorous debate. There is no perfect metal detector, no two people have exactly the same preferences: therefore a machine that some people love, some other people will not like at all. So, some posts are going to be quite critical of our products. The negative posts which are based on reason comprise a valuable source of information for guiding development of new products. Heck, there are things about some of our products that even I don't like. Sometimes I print out a critical post from the forum, take it to company management, and say "See, I told you so." I don't have anything against a post being critical. HOWEVER: I have no respect for posts which deliberately spread misinformation about us and our products. I don't even have respect for posts which deliberately spread misinformation about our competitors and their products. I've worked for several of those competitors, and on the whole I regard them favorably. Many beeperists own and use metal detectors from several different manufacturers. I have no respect for posts by people who want to complain just for the sake of complaining, about things which are not problems. I have no respect for posts by people who want to complain about something that is a problem, and love complaining so much that they then complain about attempts to resolve the problem. I have no respect for posts which are not for the purpose of engaging in discussion of metal detecting, but rather are for the purpose of creating and maintaining personal conflict quite to the disgust of others in the forum. There are probably quite a few forum denizens whose list of stuff they'd rather not see clogging up the forum is just about the same as my list. There. I done said my piece. --Dave J.

-

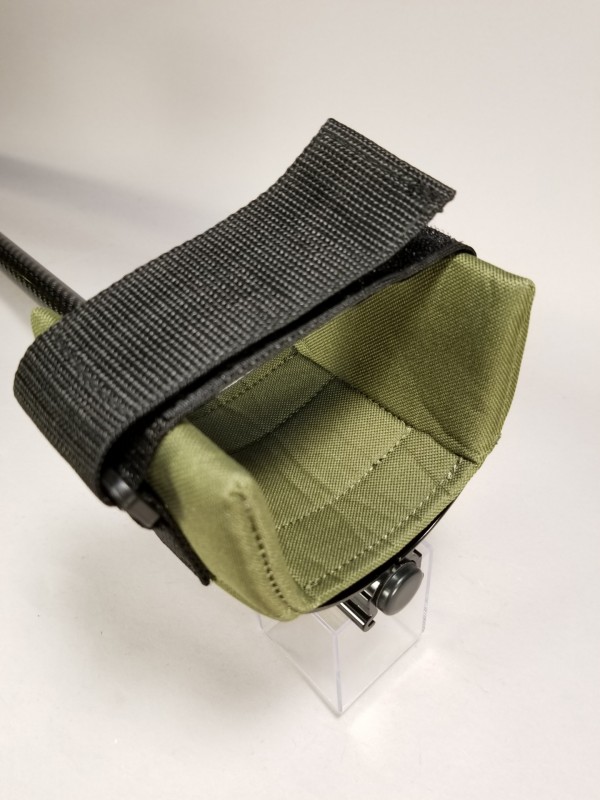

So first, we have the new Nugget Stalker padded arm cuff cover for the SD/GP/GPX series of detectors. There must he a gazillion detectors out there and no one has ever made a decent arm cuff cover to pad that steel arm cuff. Well, no more. And we are now using quality 3M hook and loop. Hook and loop inside the pockets allow you to secure the pockets of the cover to the steel arm cuff, to give a solid fit. You have no idea how comfortable this is on your arm and elbow. The cushion of the padded cuff and the way this cover cradles your arm really makes you wonder how you ever detected without this accessory. $24.95 -Doc The feedback I got from the very first one I sold on Ebay was: " A++ The Most Beautiful Item I have ever purchased, Fits my Minelab SD2200D ! " A great comment, but "The most beautiful thing he has ever purchased?" Has be been shopping at Goodwill all his life? ...however, these cuffs are extremely well made.

-

-

I bought my Simplex + from a dealer and when this same dealer has the Vanquish I may buy it too . For the cost of one detector just last year I can buy two now for maybe less money. Whatever I buy it won’t be coming from a Sports store. I can see me asking a sales person all the about the Vanquish and them reading off the box on what it had to offer. I feel that the major cause of a detector finding it’s self in the dark part of a closet is because of no help after the sale. Some years back my mom like going to garage sales and ever so often they would have a detector. The best one I got for 5 dollars and it still had foam in the battery box . I’m one that don’t have to need a detector to buy it. I find myself the enjoyment of just having it . It has nothing of being better than one other that I have but just the claim to fame that I have have it in my hot little hands. I’m the biggest kid you will ever see in a candy store where metal detectors are sold.. Chuck

-

Anyone know of any shops doing cyber monday specials?

-

Take a look. https://www.garrett.com/sport

-

How to make your great find even better. Submit in the monthly finds contests below and get free stuff or at least a moment of fame! Fisher http://www.fisherlab.com/hobby/finds.htm Garrett https://www.garrett.com/hobbysite/hb...e_find_en.aspx Minelab https://www.minelab.com/usa/community/success-stories White's https://www.whiteselectronics.com/fi...-find/ XP https://www.xpmetaldetectorsamericas.com/real-finds

-

Looks like their trying to compete with Flextronics with a for hire electronics manufacturing plant: http://www.ftpcircuits.com/ FIRST TEXAS PRODUCTS ELECTRONICS MANUFACTURING Modern manufacturing equipment, capable processes and a highly experienced workforce allow us to meet your requirements for quality and on-time delivery at a world-class competitive price. 786 PRODUCTS CREATED 984K+ GOODS SHIPPED 100% CUSTOMER SATISFACTION 17 YEARS OF EXPERIENCE

-

There is some stiff competition right now in the detector industry. We saw Tesoro go away recently, and I expect more consolidation to come. I also expect First Texas to be a survivor. The electronics industry in large part depends on economy of scale. Yes, you do need to innovate or like Tesoro you eventually die for lack of new product. But manufacturing cost is a big part of the game, especially as regards global competition. And there is no denying now detecting is long past being a U.S. based industry. First Texas has been taking some flak for slow introduction of genuinely new product, relying more of repackaging existing product for some time now. What many may not know however is that they have been investing heavily, and the big investment by far was in a new state of the art manufacturing facility. From http://www.grantcountybeat.com/news/news-releases/25974-first-texas-products-corporation-to-invest-7-2-million-on-new-el-paso-facility "December 2015 EL PASO, Texas - Both the El Paso City Council and County Commissioners Court approved economic development incentives that will spur more than $7.2 million in private investment by First Texas Products Corporation, a leading consumer electronics company with domestic and international reach. Approval for the incentive occurred by the City Council on December 8th and the Commissioners Court did the same on December 14. First Texas, which is currently headquartered in El Paso, will construct a new facility in the Mission Valley (1120 Alza Dr.), resulting in the retention of over 50 jobs which have an average annual salary of $65,331. The new facility will strengthen and expand the company's commitment to manufacturing high quality metal detectors for industrial, security and recreational purposes as well as high performance night vision devices for military and civilian markets. Per the incentive agreements with both the City and the County, First Texas Products Corporation is eligible to receive the following incentives package: City of El Paso: A ten year, 50% real and personal property tax rebate totaling $256,019 A rebate on the City's portion of the sales tax, up to $12,000 Possible waiver of building permit costs, estimated at $21,700 El Paso County: A ten year, 50% real and personal property tax rebate totaling $159,570.65 As part of the incentive agreement, First Texas Products Corporation is expected to begin construction within the next 12 months, with the certificate of occupancy being obtained within the next 24 months." This facility has been completed and is now in operation. And in a stroke of luck, I doubt FT anticipated when that article was written in 2015 that trade wars and tariffs would add an extra bonus to their decision to invest in El Paso. A peek inside the new FT state of the art facility So what does this mean? We already know First Texas makes metal detectors and night vision products. Now they have excess capability to sell. Check out the new FIRST TEXAS PRODUCTS ELECTRONICS MANUFACTURING website at http://ftpcircuits.com/ Take some time to explore that website and think about the capability described there. "First Texas Products Electronics Manufacturing understands the dynamic nature of the electronics marketplace. We offer a full range of PCB manufacturing and assembly services to fit all your printed circuit board capability needs. One-stop printed circuit board manufacturer and quick turn PCB assembly solution. Serving OEM customers for many years in a variety of markets offering PCBA, wire harness, electromechanical assembly, build box and full system integration. We also offer auxiliary services - environment testing, conformal coating, machining, packaging and labeling. One-stop printed circuit board manufacturer and quick turn PCB assembly solution. Offering some of the most advanced PCB technology and convenient services found in the industry: Full Spec PCBs, Small Quantity - Quick Turn PCBs, Custom Spec - Quick Turn PCBs, Highly Specialized Precision PCBs, & Large Scale Production." plus... "International Fulfillment Services - We are process and results driven distribution warehouse having experience with hundreds of companies globally including online marketers. Let us seamlessly be an extension of your company; manage orders and inventory like it was our own. Release your order - we pick/pack and ship using our best shipping rates. Kitting, labeling included. We have been in the procurement business for 25 years. We have the contacts and the pricing history to kit your job at a reasonable cost. Don’t hesitate to inquire about how First Texas Products can help you focus on sales and the development of your business." and finally... "First Texas Products Corporation is a consumer electronics company that manufactures metal detectors for industrial, security, and recreational purposes. The company also manufactures and distributes high performance night vision devices for the military and civilian markets. First Texas Products Corporation began operations in 1999. Today it operates more than 11 separate companies, exports to more than 110 countries and provides 397 jobs of which 254 are in El Paso. First Texas Products Corporation offers its products through retailers and dealers throughout the U.S, Canada, Europe, Latin America, Asia, Middle East, Africa, and Australia." And that my friends is why First Texas is not going anywhere. They can crank out detectors in large volumes at very low cost. How do you think I can see a pile of First Texas detectors, good detectors, at Costco by the pallet load selling for $99.99? Take engineering costs out and basic manufacturing cost is very low for these pod on a stick models. The only area First Texas probably struggles with is the old legacy devices, like the old Fisher CZ models and the Gold Bug 2. Basically hand made compared to the newest models, lower volume, which means higher component costs, and therefore they can only sell for as long as the prices can be kept high enough. With the new competition coming online many of these older models are doomed, it is just a matter of when. And I have to wonder about something like the new Fisher Impulse AQ - does it really fit with the low cost high volume business that is FTs bread and butter? I guess only time will tell. One thing I am very sure of however, is that First Texas will continue to be a player in this industry, probably for longer than I will be around.

-

Thank-you Minelab for sending this out. For some reason the store where I purchased my Equinox would not honor the RMA that Minelab issued for a replacement arm cuff. So Customer Service sent out one directly from the U.S. Boy was I surprised when I opened the package and found the entire assembly. Kudos!

-

I guess Tesoro is still alive. https://www.tesoro.com/IDS/ids.html

-

This is just me following a random coffee inspired thought. It sure seems to me there is a disconnect between what customers expect by way of communications from Minelab and what Minelab perhaps thinks they are delivering by way of customer communications. The current example of course being the Gold Monster 1000 and customer and even dealer questions about what's up with the where and when. Minelab overall probably thinks they do a pretty good job with communications. Lots of customers and dealers probably feel otherwise. Where is the disconnect? Having rubbed shoulders with some Minelab folks for awhile I can offer this. They are a very engineering driven company. Literally a whole bunch of engineers, all engineering away doing engineer things. And truthfully, just a generally nice bunch of people, fascinating to chat with. Most of you would really enjoy having the opportunity to meet and talk with them, and I am quite lucky in that regard. There is this however. How many of you know engineers? Have you spent a lot of time talking to engineers? They are not really famous for communication skills. They might think they are communicating, but they are speaking a different language. Their brains are often wired differently than "regular folks". Yeah, it is a cliche, but cliches are often based on a certain reality. Think of Minelab as a large box full of engineers. Maybe really nice engineers, but engineers nonetheless. Then you might understand the communication thing. It is not just Minelab either. Minelab comes off as Suzy Socialite compared to Tesoro for instance. The industry as a whole has been remarkably slow at embracing the internet for what are after all technology companies. Garrett probably has it figured out the most but even they have been weirdly silent on the AT Max since the initial intro blurb - no other sign of it on the website yet. If this all seems far fetched consider this. I just Googled engineer communication skills and got 42,900,000 results! I love this quote from this article "According to Weisman, engineers take a 67% risk of damaging important relationships with people every time they speak." There are some good tips in that article for the companies.