Search the Community

Showing results for tags 'detector tech'.

-

What's the difference between discrimination and notching, like is there a difference under the hood? Does discrimination give you clipped tones like notching can?? I just got a deus 1 machine so I'm curious, I am coming from nokta machines which only have notching

-

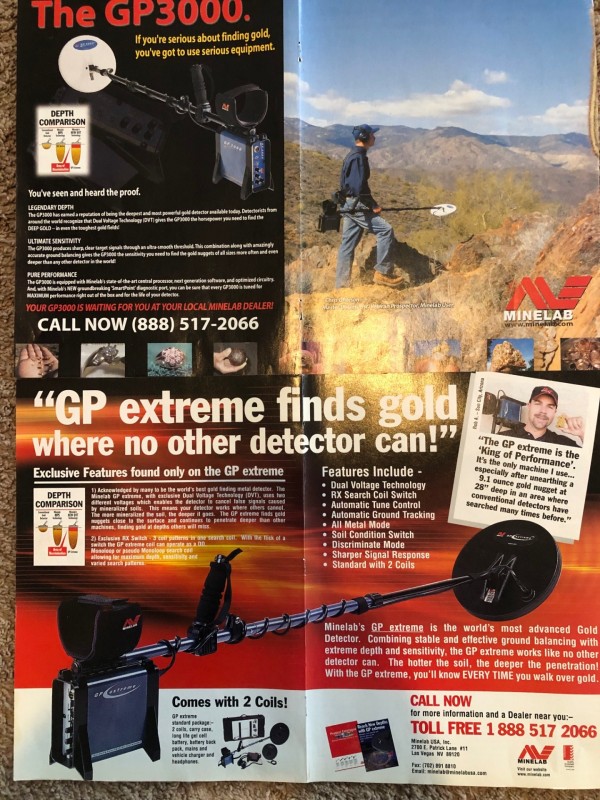

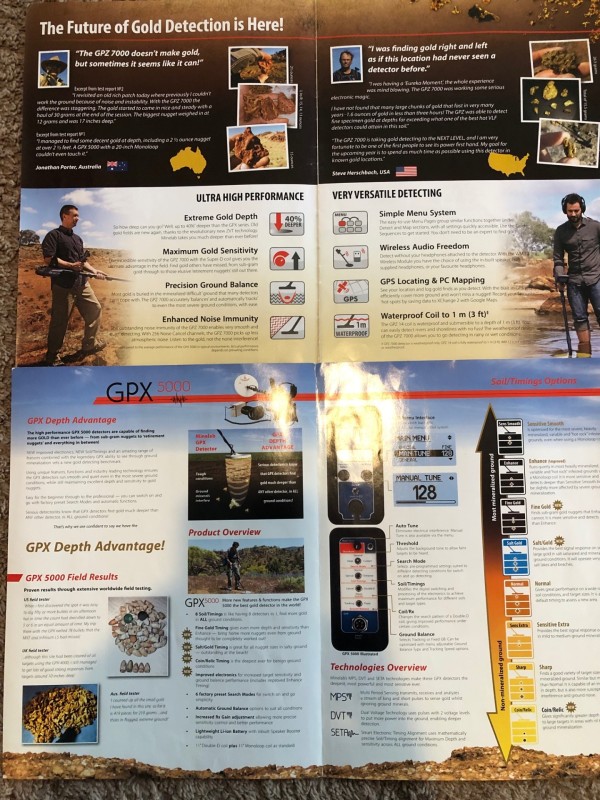

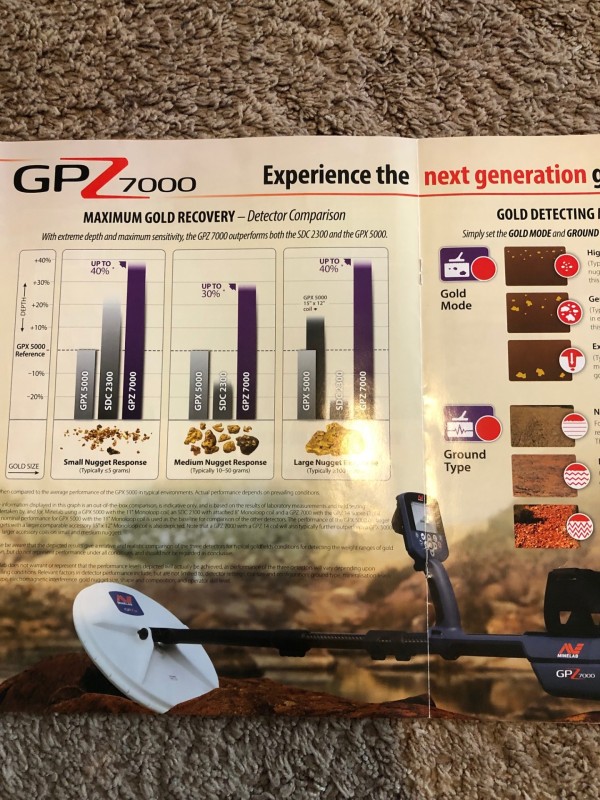

Looks like everyone is having a different copy version made of all the older Minelab technology. A definite sign Minelab needs to start filling the demand for newer better detector technologies unless of course they have hit a wall. I doubt that is the case as they have the largest electronics engineering team ever known for hobby detector development and have had these engineers on board for a long time now. Surprising they have had no new releases for such a long time in the gold detector series. So what has happened in comparison to the early years when the SD/GP/GPX releases were quite frequent, seems every 2 years or sooner then. Even though they were mostly minor upgrades until the GPX series they were enough to get the buyers interested. The GPX-5000 is about 14 years old and has been still a great selling detector, now it’s not available in the U.S. and you can only get a fake on the knock off marketplace now. SDC-2300 is 12 years old and still no Platypus coil for it. ZED is 9 years old. GM-1000 is 7 years old and still single frequency. So other companies have had plenty of time to make similar designs in a lower price range. Seems like we should have had had an upgraded wide variety and selection of the above mentioned models out by now. Give me a GPX-5500 in a light package and includes the SD2200d or original GPX-4500 depth range and Micks mods incorporated into it and you would have the professional gold hunter market covered. The GPX-6000 should have been called the GPX-auto lite since it has no larger coil options and would of been a great entry level for beginners with a lower price point than the above professional option mentioned. Hopefully things change for the better with the current Minelab corporate leadership and that they get back into the top player market again.

-

I searched the internet but, still not sure What does SAT adjustment mean on a metal detector? What is SAT. Thanks, Joe

-

Not sure if this has been posted already but this sounds interesting. According to Woody who is the maker of this new detector, it will be light-years ahead of any other detector currently available. Due possibly this year. I have no idea if the mods he does are any good or if he can create something better than what companies with many emploees/$$$ have at their disposal but I'm rooting that he can. It has an 8-pin plug, wonder why?

-

Something new. Take a look at the English manual. Instr. za SmartPulse_EN.pdfInstr. za SmartPulse_EN.pdfInstr. za SmartPulse_EN.pdf

-

-

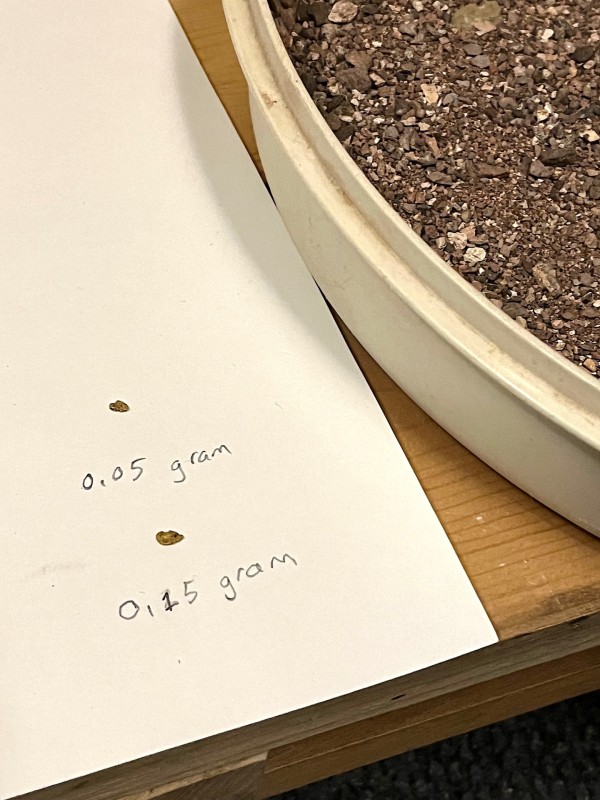

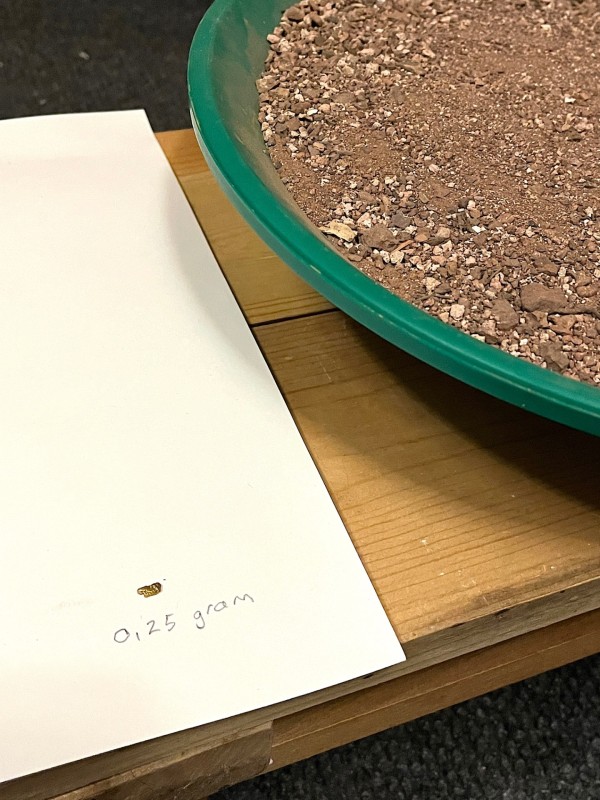

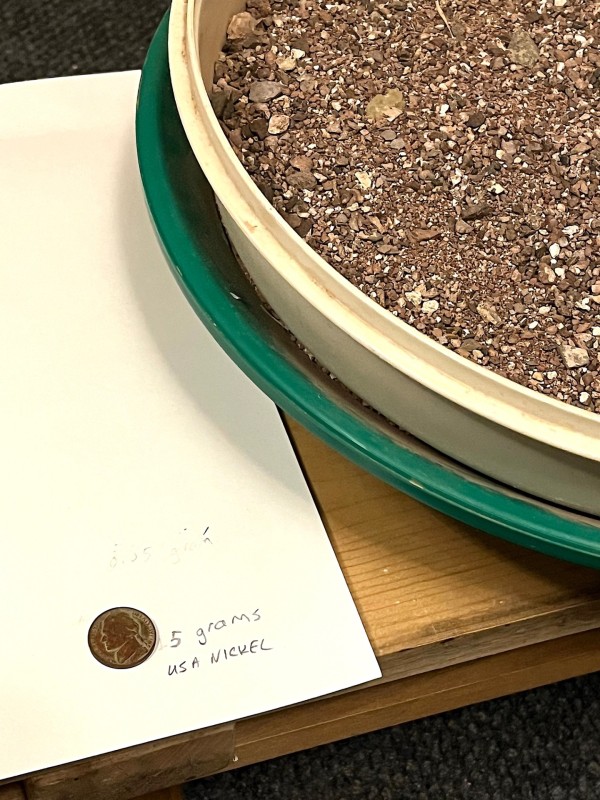

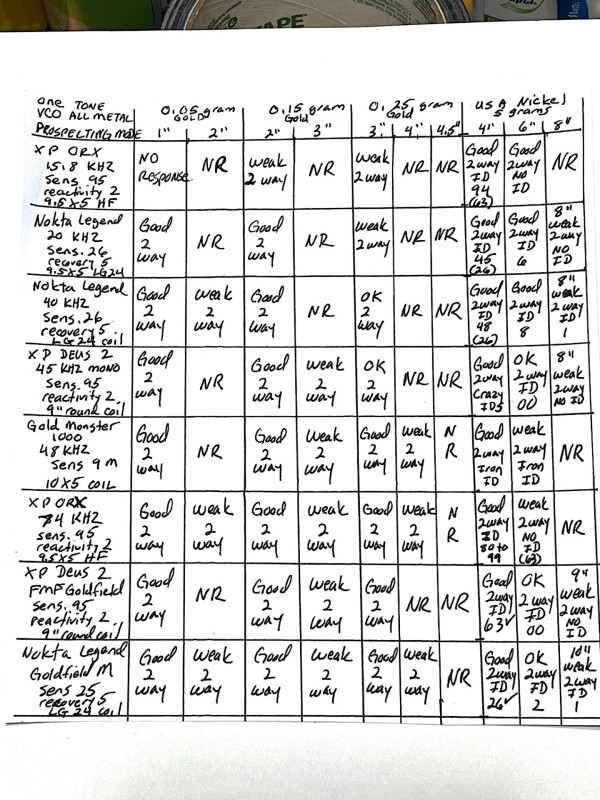

I see this question at least once every 3 months on this forum. It goes something like this...." Are dedicated single frequency gold prospecting detectors better than the latest do everything simultaneous multi frequency detectors for gold prospecting?" Maybe this bit of semi-real world testing will help some people. I wish I had a wider selection of dedicated gold prospecting detectors, especially a Garrett/Whites Gold Master 24K and a Fisher GoldBug 2. I don't. I do have a Gold Monster 1000 (for a little while) and an XP ORX with 9.5 X 5" HF coil and its great gold prospecting modes that even have a live threshold. So I tested those two detectors and used the XP ORX in 15.8 kHz to simulate several great 13 to 18 kHz detectors that have been used for gold prospecting including the Whites MXT, Fisher F75 and the Garrett AT Gold. I used the Nokta Legend in 20 kHz to simulate several 19 to 20 kHz detectors like the First Texas Gold Bug/F19/G2+/Time Ranger Pro series and the Nokta Multi Kruzer and Anfibio. I also used the Legend in 40 kHz, XP Deus 2 in Mono 45 kHz and the XP ORX in 74 kHz. The XP Deus 2 and Nokta Legend were also tested using their simultaneous multi frequency gold prospecting modes. I consider the Equinox 800 and Legend to have almost identical gold prospecting performance. Equinox 900 is slightly better from my experience and Manticore with its 8" coil appears to be even better. So, XP ORX with HF 9.5X5" elliptical coil, GM 1000 with 10X5" elliptical coil, XP Deus 2 with 9" round coil and Nokta Legend with 9.5X5" LG24 coil. I used the Nokta Legend stock headphones with wired connections for all detectors so that there would not be any variations in sound quality. All detectors were noise canceled, ground balanced (the Gold Monster used has the updated Quick Track) and all were used in 1 tone VCO audio with absolutely no target IDs rejected. Deus 2 45 kHz Mono was set on -6.4 discrimination. EMI was a problem so the single frequency detectors and selectable single frequency detectors were able to run higher sensitivity than the Legend using its SMF so keep that in mind when viewing the results. Plus I made a mistake recording the settings in the results below. The Legend using SMF Goldfield Multi had sensitivity on 23 of 30 not 25 as reported. It was fairly quiet at that 23 setting. I had to run Deus 2's SMF Goldfield at 95 just to compete and it was EMI noisy. I tried to run this test with the Manticore but I only had the stock 11" coil and EMI was unbearable. I used a 0.05 gram nugget and a 0.15 gram nugget under 1" of moderately to highly iron mineralized Arizona gold field dirt. This dirt's magnetite mineralization almost filled up both the ORX and Deus 2 iron mineralization meters. I used a 0.25 gram nugget under 3" of the same dirt. I used a 5 gram USA modern nickel under 4" of the same dirt Any depths reported beyond those were "air gap" depths swinging the coils a few to several inches above the top surface of the dirt. Here are the results: I wish I could have done this testing outdoors in the gold fields. Weather is definitely preventing that here in Colorado. Thanks for looking.

-

Detector settings are sometimes called timings. Why? How can thinking about timings help me configure my detector

-

I recently stumbled upon the use of the mono program by accident and noticed a lack of a specific data point in the mf programs. Although I understand the minimal variation in frequency multiples and the almost no importance other than to clean the signal from interference, I still noticed that between shift 0 and shift 6, the frequency can slip a lot. In my case, I suffer in saltwater from a difficulty in finding a sweet spot between 24 and 40 kHz or at least visualizing the actual setting. This is quite different from the autotune scan, believe me. I am referring to the lack of an exact kHz number that I justify with more frequencies working, but that does not help in understanding what level you are working at. If I take into account in mono 40 kHz with a 0 shift, I assume I am reaching about 32 kHz. In mf this should translate the same way with the unknown of the lowest frequency. There are missing pieces in this theory but the lack of the number of kHz relative to the shift in use does not help me.

- 21 replies

-

- advice and tips

- detector tech

-

(and 1 more)

Tagged with:

-

I have been following the recent/current controversy about the new Rutus Versa & it’s performance. Iffy Signals standardized 3D separation/unmasking tests really lit a fire. I’m glad it did because it will benefit Rutus, the new Versa & anyone who is objective and thoughtful. I am not a big fan of Social Media but You tube has proved invaluable in speeding not only some hurt feelings, but reproof & useful information/instruction. I’m sure l would have eventually figured out how to correctly set up the machine to pass this test & more effectively unmask in iron trash. I already know to do this with the Legend, MXT, Anfibio, F5,,,well,,,all my other machines. Surprise? But the Versa is a little different in design for tone break/Disc/Iron volume and there is a lot of information detail lost in the translation of language. Are people too quick to put up videos? No, I want to see it in action. Are people to quick to give an opinion? No, I will consider the source & make up my own mind. Are the self appointed “experts” too quick to pass Final Judgment? Most certainly. We saw this same storyline with the Deus 2, Legend, Manticore, Equinox 900 and every other introduction. They have all been better explained/understood & improved upon, thanks to controversy and the reach & speed of Social Media and passionate users & responsive manufacturers. Dang, now l have to re-hunt those same areas where the Versa already pulled some masked targets out of that had been missed by my other properly adjusted machines.

-

Hey y'all, There wasn't much going on today, my wife said "why don't you go detecting?" I'm not the kind of guy that says "are you sure?" 😀 I had something in mind and went and did it. If you've been reading my insane diatribes 🙄, you know I had a problem with my first remote (RC), sent it off to XP service, and it came back 11 days later. I had bought a second remote so there wouldn't be any downtime (yet another post), updated both of them to V2, and shipped the old one off. I've been wondering whether there have been any hidden changes in hardware, and was eager to find out. I bought my first remote in February 2022, and the second this past November. I sat down with both remotes and made sure the program I was using was exactly the same on both, kind of a painful process. 😀 What I'm using is a new program based on General, similar to my old Relic Reaper that V1 trashed. I built this program on the fly recently using some parameters from my summer beach program that was very successful. Heck it even works great on the farms here because there are salts everywhere, but I wanted manual ground balance which Beach Sensitive doesn't do well, and moisture subtraction. My ground balances from 67-80, usually around 76 when it's wet. Really no minerals at all. I never see any mineralization bars on the main screen, so I use XY for other info and audio response tells me size/depth. I used both remotes in the field right in front of my house, just gridded the farm about 10 feet past the underground power line and far enough away from my RV with WiFi, a spot with no EMI at all. I have to say from making many passes with both that there was no variance in the tones, bump sensitivity was exactly the same, and found there were no differences at all. 👍 That mission was accomplished. Now for an observation: The coolest thing was that because I had my WSA II headphones, the same pinpointer, and the same coil (11x13") connected to both RCs, all I had to do was throw the remote on and go. I guess the peripheral devices don't maintain the pairing records, only the RC does, so all other devices will work passively without re-pairing them if they have been connected before. Change out something and you will have to redo the first one, as you have deleted its pairing record with the RC. I really like that. 🙂 I didn't find any relics or coins in this spot, just some small trash: Headstamps, buck balls, the usual junk. The field in this area is pretty clean because it used to be the middle of the field, the turn zone was way behind my house. It has a lot of different conditions from clean to ridiculous, however. There was a farmhouse out there long ago. While I was out there an Amazon driver came and delivered the new glass screen protector kit from XP: https://www.amazon.com/gp/aw/d/B0C486BLPC It costs about 8 bucks but it is great. The screen on my old remote was scratched big time, but putting the glass protector over it covered everything with no bubbles. It looks relatively new now, and the screen has tempered glass over it. I don't know why they put the notch in the glass, maybe it's so you can get it out. I'm very pleased. 👍 Just for giggles I might roll back one of the remotes to V0.71 to see what differences there are, and post some more observations. It's easy enough to do. 🙂 While I was out doing all this, a guy came flying over the field in some sort of para-plane. 😀 Pretty cool. Here's a bonus sunset from last night: Happy new year! 🥳

-

Hi everybody, this is Dave, I've been dabbling in metal detecting about 8 years now. Most of my experience is with PI units specially Lorenz (X6 and older models) for relic objects. Unfortunately, my X6 got serious damage and it is useless now. I am considering a Pulse Star II pro unit; my needs are for a PI unit that can detect a 25*25 cm (9inch by 9inch) object in the range of 2.5 m to 3 m (8 to 10 feet). Because of limited budget (under 3000$), and technical features I did choose Pulse Star ii Pro, but I could not find enough reviews on the unit. It would be great help if I can have your experience and feedback on it. Is it reliable? Robust? Can it meet my expectations (8 to 10 feet depth)? Also, do you suggest another PI unit in same budget? Appreciate your help very much. Good luck for you all.

-

Can anyone tell me with a successful homemade metal detectors that finds gold. If you struggling with a homemade detector for finding gold if you need help i have many ideas to help.

-

I'm hoping someone can help me out here. I'm not looking for Gold, but I need a detector to pick up some Copper wire. I have a Construction Company in South Texas and we are digging in areas that have buried pipelines. Several of these lines are fiberglass and have copper wire (as a tracer) is laid with these lines to be able to trace them later and prevent damage when excavation of the area is necessary. Normally, one can use a line-finder to locate them, but only if you know the beginning or termination points of the line. Because in those instances, where the line enters and exits the ground there are terminals to attach your ground enabling the line-finder to operate correctly and detect the copper line. In our situation we do not know where these entry or exit locations are, so we can only use metal detectors to find the steel pipelines, but it is not working for the fiberglass of course. I was thinking that since Copper is a Non-ferrous metal, as is Gold, that a Gold locator would work. Is my thinking correct? The real problem I believe, is in the fact that this Copper wire is around three (3) foot deep and only 10 gauge. It's not very large in diameter, but it is a continuous run. Does anyone have any suggestions as to the best Gold detector for my needs? Cost is of no concern as the cost of repair to the damaged lines will more than offset the cost of the detector. Thank you in advance for your time.

-

Gotta hand it to the dude taking the time- that said found on a youtube link back to someones homepage. Safe link Seriously it would appear, and forgive me for jumping to conclusions, but..I'm on the verge of being comfortable saying.......if you, and yes, I'm going for it..if you dig everything that crosses with any sort of constancy, you will dig trash, but you will also dig good things.. there. I said it frigging gold rings/beeps/vdi's from 1 to 70...perfect https://calabashdiggeradvenutres.uscreen.io/programs/gold-map-manticore-neu-c6295b?category_id=185966

-

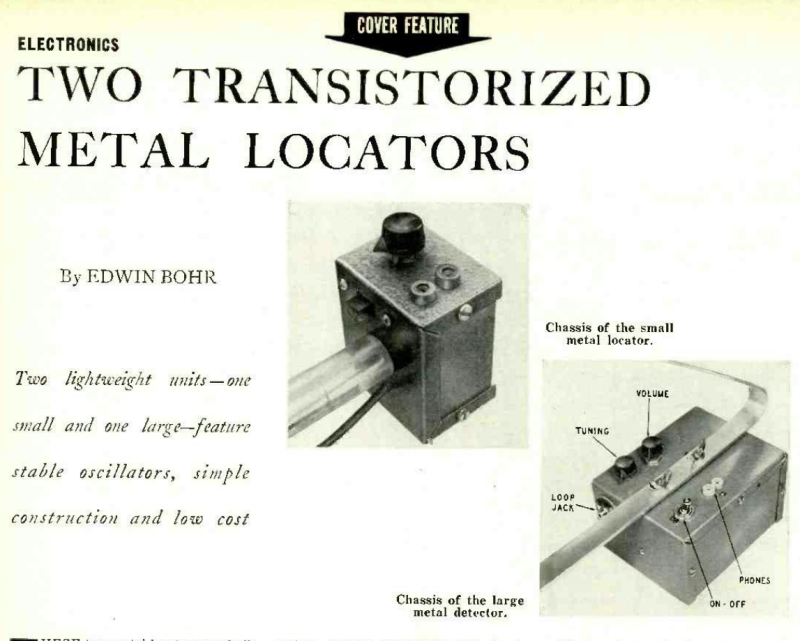

Hi guys and Gals, I'm new here but been hunting since 1964. I'm an Radio Frequency Electronics Engineer. I design and build all kinds of Radio Frequency devices. I have been thinking about building my own pick up loop coils. I built some years ago when I worked for a fledgling metal detector company back in the MetroTec Days. If I recall correctly it was for a BFO type detector. I am now working with VLF Motion Detection and Descriminate type detectors, and a few Pulse Induction (PI) units. Most units operate between 3.0 and 40.0 KHz. Any input would be appreciated. Thank you 😊 Laurin the old SwampFox

-

Update: Thanks to the good advice here I was able to remove the stickers from my cracked detector cover without damaging them. I applied heat from the inside of the old cover to protect the stickers from damage but I did overheat the plastic itself which is not a problem since it was cracked anyway. Any advice on what adhesive would be best for attaching the graphics to the replacement cover? I recently found a new control box cover for my old White's PI Pro detector but it is just clear plastic. I'd like to remove the decals/labels from the old cover (pictured) and put them on the new cover. Is there a solvent that would break down the adhesive without damaging the decals? Thanks for any suggestions on this.

-

Some of us are challenged by the 'technology' of metal detecting and don't have a clear understanding of what happens when we swing a coil. I'm in that category. I'm a 'user' and respond to the detector without thorough understanding of what is happening. I just read this description of how metal detectors work and it will probably change what I think about when I am now swinging a coil. Is this an accurate, basic description of how we hear a detected object? How Metal Detectors Work | HowStuffWorks

-

Recently detected a ferrous rich old mining site for coins & relics using the Minelab EQX 900 experimenting with Park 1 in multi-frequency with factory settings except All Tunes and Iron Bias 2. A road crew was working within a 1/4 of a mile. The detector was definitely picking up EMI from the flagmen radio traffic. There is also an electrical power plant 4 miles line of sight to the north, an overhead high voltage electrical line 12 miles line of sight to the east and a mountaintop microwave station 14 miles line of sight to the northwest. Performed multiple frequency scans and adjusted the sensitivity down to 15 and below, neither reduced the EMI noise level. Five hours later the road crew departed but the EMI grew even stronger. (The power plant gearing up as folks return home from work?) The racket from the EMI was both tiring and annoying but I was able to separate out non-ferrous targets. I have detected this area for years with several single frequency & selectable frequency VLF detectors ranging from 15kHz to 54 KHz plus pulse induction detectors. I have never experienced this level of EMI in this area. I have been using Park 1 and Field 1 in an attempt to pull out deeper high conductors on heavy ferrous trash sites. Apparently that is a no go with SMF in either of these two search modes. The mining site is blanketed with ferrous trash, gold 1 & 2 would require a dig all approach without discrimination. It appears at this point the only option is Park 2 and Field 2 in either multi or single frequency. Has anyone else experienced this EMI problem with a SMF detector?

-

I've used BBS and FBS machines for shallow saltwater jewelry hunting. I've not been on a treasure hunting vacation since COVID, but have since accuired a DEUS II and a Notka Legend. I've been watching vids online and wonder why so many on a wet salt sand beach, GB these newer multi-frequency machines- even in beach/dive mode? Now, I did try 3 leaky Equinox and found less gold and far more small pieces of junk, so clearly the new machines are more sensitive to small, tiny targets. But I always found far more big gold, silver and platinum jewelry using BBS/FBS, with less time spent scooping small junk. My concern as a shallow saltwater jewelry hunter is, what's with all this GBing at the wet salt beach with the newer MF units? So many newer MF machines sound sparky when they hit the surf/wet salt sand and the operator GBs to quiet the machine down. I have never GBd using BBS/FBS in the sea, or going from saltwater/wet to dry sand. That's one reason I've found my share with BBS/FBS machines. They're simple and effective in the surf. What is BBS/FBS doing to compensate automatically for salt and ground and what's the difference between BBS/FBS and all the newer MF machines, which seem to require GB at the beach? Would one GB the new MF machines in saltwater? I always thought MF- (BBS/FBS) resolved VLF problems at the salt beach? Is it because the new MF machines are more sensitive, or is BBS/FBS multi-frequency a different breed all together? I wonder if I really should switch to these new MF machines for shallow saltwater hunting? I found far less using the Equinox the few times I tried them. (3 leaked!/ and why I did not grab a Manticore) I do like the simplicity of the Legend and how small it packs for travel, and I sure like the Deus II. But so far everything in my test garden those 2 can hit, so can an FBS Safari, I loan to non-detecting friends. I still have my trusty Excalibur, but am thinking about getting another CTX 3030 for hunting shallow surf. Those who jewelry hunt in surf with the newer MF machines, are they as quiet/simple as BBS/FBS? Thanks!

-

Hello...can anyone recommend a good long distance gold detector? I'm considering investing in one.. Thanks

-

Assume the last remaining metal detector manufacturer produced only two (2) models of the same detector with all the same features; the only adjustments you could make were ground balance, EMI and volume control. All the other features, filters, the coil, etc are identical but factory set & locked and not adjustable plus there is only one (1) all-terrain/all-target search mode. The only difference between the two detectors is one offers a range (4 thru 60) of Simultaneous Multi Frequency (SMF); the second detector offers multiple selectable frequencies (4, 5, 7, 10, 15, 18, 30, 40, 50, 60) which you select. Just before the last manufacturer files for bankruptcy they offer a midnight sale with free international shipping but you are limited to only one (1) of remaining two (2) metal detectors. Which Metal Detector would you purchase and why ?

-

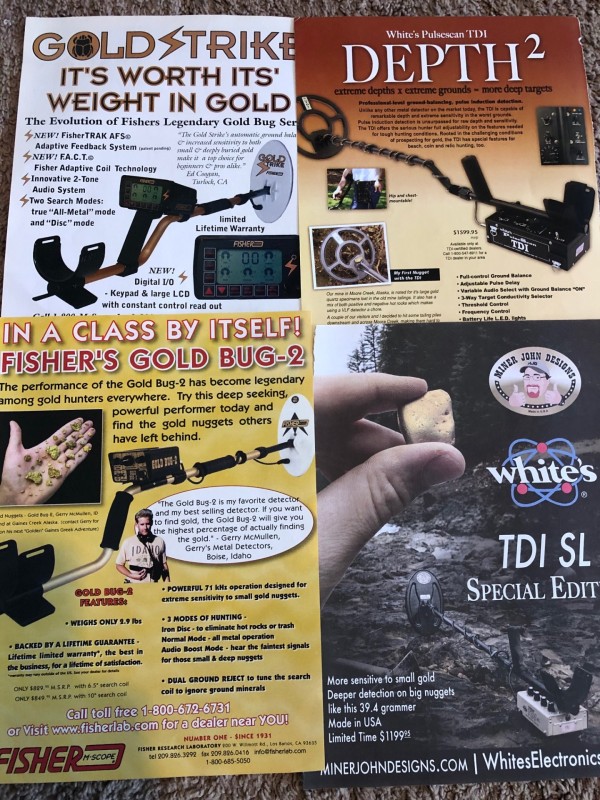

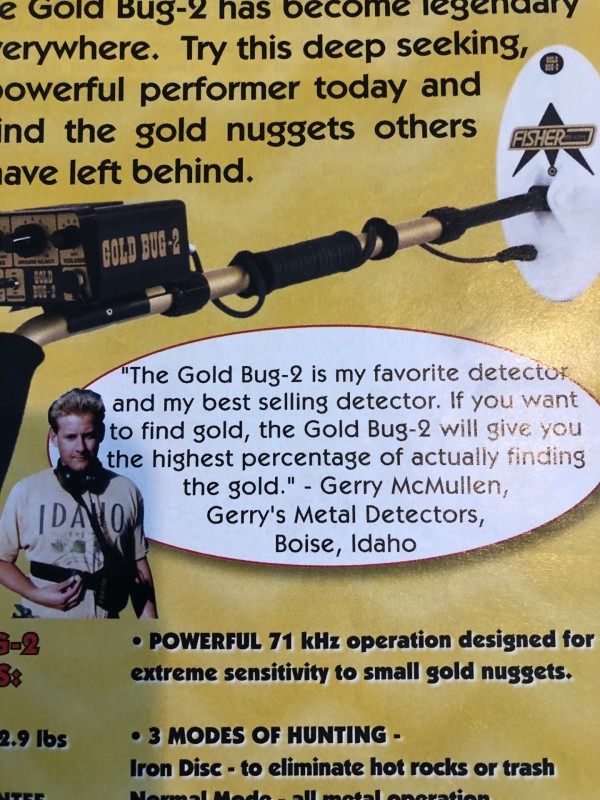

So what sells metal detectors these days? A lot of the market now is driven by “influencers” on YouTube and other social media. There is no requirement that the person involved have any genuine knowledge about what they are talking about. All that matters, and I mean all that matters, is how big their viewership is. That’s the way the media works these days. Truth, accuracy, etc. are completely secondary to how many eyeballs you can draw. In fact you can have a show or channel about complete BS and as long as you can draw viewers in large numbers, you are golden. Metal detector video by nature tends to rely on contrived tests. The most widely seen is perhaps the Monte Nail Board test. But there are endless variations of tests using wood blocks and styrofoam blocks, you name it. These all remove the most important thing about a detector - how well does it separate the target from the ground? Ground conditions (wet, dry, salty, 3D trash density) and magnetic mineralization rule everything from depth to target id accuracy. But that does not matter. What is important is it is popular and people believe it. So the manufacturers do now pay attention to producing detectors that perform well in these videos, and if performing well in the videos means maybe not so well in the ground at the end of the day you do what you need to do to sell metal detectors. Thats job one - sell metal detectors. This reliance on these types of tests and the people who do them go a long way to explaining why recent detectors do well with the YouTubers but not so well with the people that really use them. This forum tends to downplay contrived tests in favor of actual in field use on actual found targets, by expert users. The answers often are nuanced and lack the clear quick black and white the marketers need to sell the product. Finding the truth on the Manticore means reading 100 posts or more on the subject by a wide number of different real world users in different locations. The truth emerges over time, not in a five minute video shot by a guy who has had the detector for three days, if that. To sum up though it all comes back to how important it has become to do well in air tests and the Monte test, with actual stable performance in the ground being a secondary factor. And unfortunately a detector jacked up to do well in the air does not often do all that well in the ground. I relayed this story before. I was at my Moore Creek Mine in Alaska, and a visitor arrived with a Fisher 71 kHz Gold Bug 2. I was swinging a Fisher 13 kHz F75 at the time. He thought I was an idiot as he knew for a fact his Gold Bug 2 did better on gold than the F75. Now mind you, the goal at Moore Creek was 1/4 ounce and larger nuggets. Those were daily finds with 1-3 ounce nuggets common. He was pretty adamant so I said “here, let me show you something.” We took a 1/4 ounce nugget and air tested both machines. The Gold Bug 2 easily trounced the F75 and I could see the smirk on his face from the result. Then we buried the nugget in the ground. The F75 easily hit the nugget beyond the point where the Gold Bug 2 would even signal at all, and not by a thin margin. The guy was astounded. But he simply did not know that high frequencies air test well but fall on their face for penetration in bad ground on larger targets compared to lower frequency detectors. The same error is made repeatedly with PI detectors, either testing them against VLF detectors in the air or in low mineral ground. PI basically exists as a solution for extreme conditions, and testing them outside those extreme conditions is not only inaccurate but highly misleading. The same can be said of any this versus that VLF tests that remove the ground from the equation. It’s just not as dramatic as with PI versus VLF, but it is real all the same. When you are spitting hairs like so many people do these days taking ground out of the equation is ridiculous.

-

I do understand that (at least in the Deus world) discriminated targets still gives an iron sound, and notch is silent. Also that you can have multiple ranges of notching and that they don't have to start at (or below) 0. I've got that. But internally, programatically/technically why do we have both? Does one affect depth or speed of processing more than the other? Any other differences?

.thumb.jpg.8761b3d9b3da119b9e6d1912f67275ad.jpg)