Search the Community

Showing results for tags 'detector tech'.

-

A detector should have individual character and a distinguishing trait or quality. Isn't this why we buy that detector ? When you have a detector company that makes their product under one name you find what I said more true. Then other companies may have one name but they sell their products under different brand names of times past. I'm not saying it is not a good product they have. The trouble that comes into play is when they have the same father they start to look alike.Just by association and being conceive by the same person they all are going to be effected. If you go look at detectors that come out under different names but made by the same company you will see what I'm taking about. Oh it don't jump out and bite you but makes you think your seeing double. I don't care if it's the inner working are the skin on the outside it drift from one to the other. Okay I open this can of worms and now I'd like to hear from you on the above subject. Chuck

-

Just found this on the web: http://md-hunter.com/garrett-at-concept-new-2016-or-a-fake/ Looks interesting.

-

This is purely my perception but when I look at the market as a whole today there are only two companies that seem to produce machines that innovate - Minelab and XP with the Deus. Everyone else just keeps rehashing the 1990s over and over again. Take away single frequency VLF detectors and non-ground balancing PI detectors from current lineups and look at what is left to get the real picture. First Texas - Fisher CZ3D and CZ21, multi-frequency 5 kHz and 15 kHz Garrett - ATX, multi-period ground balancing PI Tesoro - Nothing White's - V3i & VX3, multi or selectable frequency 2.5, 7.5, and 22.5 kHz; Beachhunter ID, multi frequency 3 kHz and 15 kHz; TDI, single channel ground balancing PI XP - Deus, selectable frequency 4, 8, 12, and 18 kHz Minelab - GPZ 7000, Zero Voltage Technology GPX 5000, multi-period ground balancing PI with dual voltage technology GPX 4500, multi-period ground balancing PI with dual voltage technology SDC 2300, multi-period fast ground balancing PI Eureka Gold, selectable frequency 6.4, 20, and 60 kHz X-Terra 705, 505, 305 - selectable frequency 3, 7.5, and 18.75 kHz CTX 3030, multi-frequency E-TRAC, multi-frequency Safari, multi-frequency Excalibur, multi-frequency It is even worse when you consider that the First Texas and White's offerings are all over ten years old. You can sum new tech up in the last decade as Minelab, Garrett with the ATX, and XP with the Deus.

-

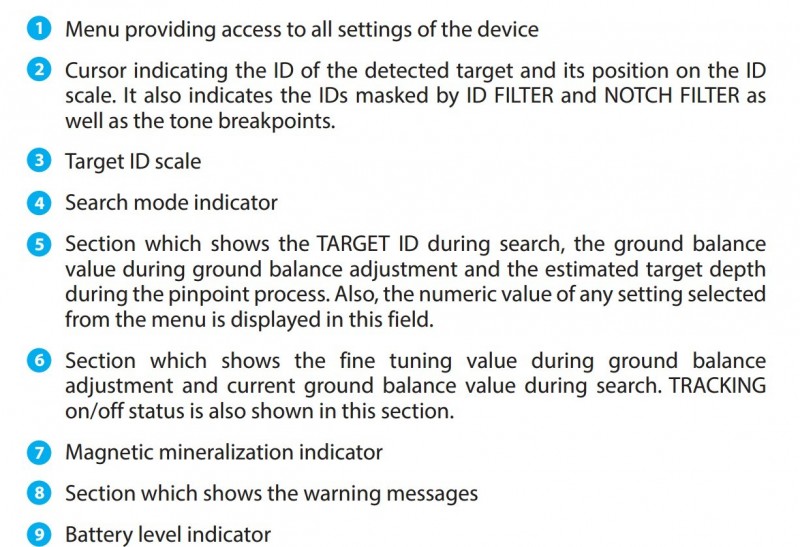

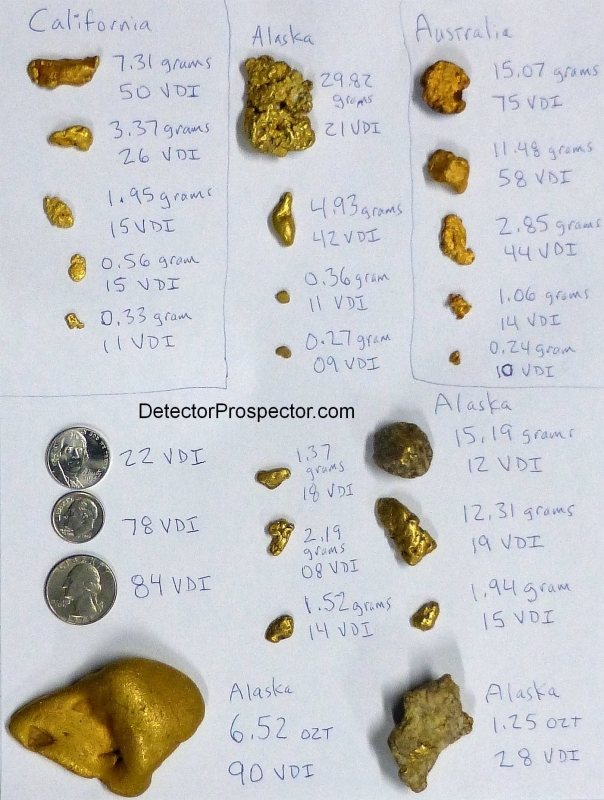

Here is a photo with some gold nuggets from Alaska, Australia, and California that I tested recently to show how VDI (visual display indicator) numbers vary dramatically with size, shape, and purity. Metal detectors do not know what metal is being detected. The target id number is based first on the conductivity of the item and also by the size of the item. Low conductive targets have low numbers, but the larger they are the higher the numbers go. Silver is the best conductor with gold being moderately conductive by comparison. Small gold items read very low, in the foil range, but the larger the nugget, the higher the numbers will go. Oddly enough adding silver to gold causes the conductivity to drop dramatically instead of adding to it. Pure metals are far better conductors than alloys. That being the case the Alaska gold has much lower conductivity than the Aussie or California gold. I have always used a U.S. nickel as a surrogate for about a 1/4 ounce gold nugget, a flattened nugget of that weight being close to a nickel in physical size. Part of this little study is to show how close to reality or not that may be, or any test items like lead or aluminum. I do not have much in the way of “normal” metal detectors these days. The closest I have right now is a White’s DFX which reads a nickel as 22 VDI, dime 78, and quarter 84. The White's VDI range is close to being a standard, with negative numbers relating to ground minerals and ferrous items, positive number non-ferrous. The range is from -95 to +95 with non-ferrous items falling between 1 and 95. The photo shows tests I just did on a variety of gold nuggets from Alaska, Australia, and California. The Australia gold is the purest, probably around 95% or better. The California is around 90% plus. The Alaska gold is much lower purity, closer to 80 – 85% average. You can see the purity differences in the color - pure gold is a very rich gold color, less pure gold much paler in appearance. Click for larger version.... Gold nugget target id numbers A few things become immediately obvious. Larger size means higher VDI numbers. However, purity appears to be even more important. Shape, thickness, and solidity all matter – skin effects? Smooth solid masses read much higher than nuggets with pitted surfaces. All weights are in grams except a couple larger nuggets which are Troy ounces (ozt). There are 15.43 grains to a gram. 31.103 grams per Troy ounce. In general in all three locales you can say that nuggets under 2 grams are going to read in the foil range. As nugget size increases however huge disparities are obvious due to purity, with all but the largest Alaska gold reading at much lower VDI ranges, and Australia gold very high numbers. There are some odd ones that prove the situation. The Alaska 29.82 gram nugget is just under one ounce, but VDI 21, almost an exact nickel reading. This is because this nugget is probably 75% - 80% gold. You can see the color difference compared to the Australian gold next to it. It also is deeply pitted. The 4.93 gram nugget directly under it is solid and smooth and about 85% pure and so has a VDI number double what you see in the much larger nugget. The Alaska 15.19 gram is round and solid but has quartz mixed with it, maybe 80% gold in metallic portion, only 12 VDI. The 1.25 oz Alaska in lower right has a lot of quartz and metallic portion is maybe 75% gold, so only 28 VDI. But get big enough, and at 6.52 ounces, 85% gold, solid and smooth, you get a reading up in half dollar 90 VDI range. For California gold I am guessing that at about 3 grams you get a nickel reading but in Australia it might be closer to 1.5 grams, and in Alaska closer to ½ ounce. Bottom line? The nugget size to get a U.S. nickel reading is all over the map from roughly 3 grams to 15 grams but can go up to nearly an ounce for nuggets of low purity with included quartz and pitted surfaces. Saying a U.S. nickel is roughly equivalent to a 1/4 oz nugget can be true and is probably as close as you will get to some sort of average, but reality is the range of nuggets that have a VDI the same as a nickel is pretty surprising. The final zinger is that these are air tests. Ground minerals will change the numbers, typically pulling them down. The worse the ground mineralization, the lower the numbers will shift. There are a few lessons here. The first being that if you know nothing about the gold you are chasing you need to dig all targets or at a minimum all non-ferrous targets. However, if you do have a target id detector and get to know the gold in your location well, you can cherry pick with some degree of accuracy. The number one factor really is size because large nuggets are very rare. Certain areas despite wishful thinking simply do not produce large gold. If you know for a fact all the gold ever found in an area is in small gram size nuggets and even smaller, you can figure high VDI numbers are probably shell casings or some other undesired target. Further, in places like Alaska with low purity gold (not all of it - Alaska is a big place) then low VDI numbers will be the norm. The numbers speak for themselves however and you can draw whatever conclusions you want. I have to admit that while I know all this intellectually from years of detecting to see it laid out clearly in a simple photo really drives the lesson home. It took rounding up some Australia gold and California gold to really make it a good comparison. To further illustrate that gold as a rough rule boils down to "the larger the gold, the higher the target id number" here is the standard White's scale as printed on several top end metal detector control boxes. It shows where gold coins, gold rings, and gold nuggets generally fall on the White's -95 to +95 scale where negative numbers are normally ferrous. Pay extreme attention to the fact that White's says small gold can fall as low as -20 on their scale - deep into the ferrous range. At the other extreme a $20 gold coin may read as high as a silver dime or quarter. The gold range covers the majority of the metal detector target id scale. White's Electronics standard target id scale -95 to +95

-

What's in the ultimate gold detector? I got to see a little bit of everything on my trip from the heaviest, most complicated to the light and simple. I'm a novice, maybe because of that I like simple. Knobs instead of menus. Light. Powerful. Long battery life. For fancy stuff like GPS I can use my phone. Iron ID would be nice. What's your idea of the best gold detector?

-

Meet The Metal Detectives - Inside Engineering at Minelab Electronics A new video showing Minelabs new engineering facility and meeting some of the people that work there. Check out the blurred portions obscuring secret product developments! Amazing engineering staff at Minelab - I consider myself fortunate to have communicated with and even met a few of the people that work there. A few more details about the making of the video at Minelab's Treasure Talk Blog

-

I have often wondered about the difference in these to metals because we often use lead to test machines or coils and it seems that the Two are quite far apart, It works out that lead is 41% lighter than Gold when compared to A 1 cubic foot Block of Gold to a cubic foot of lead, So if a person uses a 0.05 gram piece of lead to test the depth of a coil it would be 41% larger than an equal size in weight in Gold . Giving you a false example of real world testing This topic has come up before on other forums where people have just compared the two signals saying that lead hits louder but that is not the case because after doing the maths the reason it is louder is because it is that much bigger as in 1.6992 times heavier because one cubic cm of lead weighs 11.37 grams and one cubic cm of Gold weighs 19.32, So when you find an 0.03 gram piece of Gold and you want to simulate finding such a small piece then the piece of lead you need should weigh 0.0176 grams and an 0.05 gm of Gold is equal in size to 0.0294 gram piece of Lead or rounded off at (0.03 grams). Adding to this a cube of Gold that measure 14" square would weigh about One Ton Cubic foot of 24c pure Gold=1204 lbs/cf > (1) Cubic foot of Rolled Lead= 711 lbs/cf A difference of 493 pounds in a 12 inch x 12 inch x 12 inch cube. Anyway this is just something to bare in mind when a person is trying to test out machines and coils when you do not have access to tiny nuggets. John

-

Ok....it is almost June 2016. It seems so far this year we have seen some entry level detectors and an attempt at rehashing previously released detectors. Just trying to be real here, but we have not seen anything really innovative since the Minelab 7000....and that was nearly a year and a half ago. Now I know, VLF technology has probable reached its limits, and even PI's are nothing new. However, I would have at least thought that one of the major manufactures would have thrown us a bone or two. WHERE ARE ALL THE NEW DETECTORS ??

-

My recent experiences with new model metal detectors has convinced me of two things. First, I want every new model I might consider going forward to have built in wireless headphone capability. It eliminates the issues surrounding where to place a headphone connection on the metal detector itself, and also eliminates the possibility of a cord failure. Stress on the cord and eventual breakage is the number one reason headphones fail. Headphones, if included or optional, would be best if they had the ability to go wireless or use an optional cord, in case the headphone battery gives out in the middle of a hunt. Second, high end new models should have an ability to have the firmware updated at home by the owner. It has become nearly normal for there to be firmware updates, even multiple updates, in the first year after a new detector is released. I am not talking about getting new features for free, although that would be nice. I am talking about it becoming apparent that a bug exists or something was overlooked, requiring an update to the firmware. Nobody should have to go through time and expense to have to return a metal detector to the factory to get a firmware bug fix. There are just too many new detectors becoming available these days, and I decided I need to draw a line on certain features to help eliminate the majority that are just variations on what we already have. Right now the market is flooded with 13 - 19 kHz single frequency detectors and more arriving every month it seems. Yet models with built in wireless headphone capability are almost non-existent. Given that basic single frequency VLF tech is maxed out, it only stands to reason that manufacturers need to be looking hard at ergonomics and extra features like wireless capability to differentiate themselves from everyone else. It is after all the 21st century. Maybe I can't get my flying car yet, but asking for these two features in new detectors is not asking too much. My current core units: Garrett ATX - N/A Makro Gold Racer - Includes wireless headphone capability as an option Minelab CTX 3030 - Includes both wireless headphone and firmware update capability Minelab GPZ 7000 - Includes both wireless headphone and firmware update capability White's DFX - N/A XP Deus - Includes both wireless headphone and firmware update capability

-

I've seen metal detectors in stores and shows for thirty years, but am only now thinking about them like I'll own one within a few weeks. Maybe this is too sci-fi of an idea, but given the popularity of the wireless XP Deus (the name! god and an outdated operating system), and the ubiquity of smart phones, when will we see a mfr put the computing power of a smart phone to work? Put a digitizer in the coil, broadcast the signal to the phone, where the processing happens, perhaps with highly customizable features (user programmable?), then bluetooth to send the audio to headphones... Graphics happen on the phone from its secure position on the handle... Too crazy? Too simplistic?

-

First, I want to say this is one of the best forums I have ever seen. Steve has put together a GREAT website. The knowledge base on the forum is just phenomenal. I have learned so so much more about metal detectors from all of you. So let me explain assumed. I assumed: White's and Garret were the best metal detectors. Carl Moreland was still working for White's Metal detectors were 10 years behind technology of today. (just my thought) After making the assumptions, I realized how wrong I was thanks to this forum. I realized White' and Garrett have been a sleep. Carl Moreland either quit or was fired. White's and Garrett detector are whats 10 behind. When I got back into metal detecting last year. I was looking for a new machine. I looked at White's and Garrett with the assumptions. I thought about building my own detector. So I read Carl Moreland's book. (Great book) I realized that it would take me 2 to 5 years to develop my own detector. So I scrapped this idea. I could not understand why White's or Garrett had not built a detector with what I expected. I thought that with today's technology there should be a sweep frequency oscillator for the coil-s and an easy to read display. That being said, White's closest model was the V3i. Garrett had nothing. I quickly realized that I needed to look at everything. Because of the forum, I found Minelab was being discussed. When I found the Minelad Safari, I quickly realized it had what I was thinking of building. I don't like their LCD display. It does not look clear a crisp to me. However the machine looks promising. Then I looked at the E-track and CTX-3030. These also look to be very promising machines. Just the price is higher that I want to pay for a -2 times a month hobby. I really wish the best for White's and Garrett. They have their work cut out for them. I want to thank John, Chuck, Tom and Terry and many others I do not know their names for the knowledge your provided and a special thank you to Steve H for his superior knowledge and the wonderful website he has provided.

-

Steve's Law of Target Depletion - All good locations with high value targets will be detected with progressively more aggressive means until no metal can be found. When any location contains items of great perceived value, detector technology will normally be applied in reverse order of aggressiveness. First will be VLF discrimination "cherry picking". This will be followed by varying degrees of "turning down the discrimination" to dig iffy targets and then on to using the barest of ferrous/non-ferrous discrimination. This will finally be followed by "all metal" detecting to remove masking effects with either VLF or PI detectors. If the location is considered good enough all targets will eventually over time be completely removed until no detector is able to acquire a target. At this point a site may be considered "hunted out" until a new technology arrives allowing for more depth or ground separation capability, when a few more remaining metal items will be removed. The key concept is that since discrimination is unreliable, all metal items must be removed from high value locations in order to rest assured nothing has been overlooked. Nugget hunters and beach hunters get right with the program. If a nugget "patch" is located it will be relentlessly pounded until no metal remains. Beaches survive to some degree by being a renewable resource but even on beaches the richer, older deposits of jewelry are worked out over time. Good relic locations can and will be subjected to the same attention given to nugget patches, detected relentlessly until no metal remains. The rule is that as long as you can find a piece of metal hope remains that good items can be found. If not you, somebody else can and will return until no metal remains. I have promoted PI detectors for all uses for this very reason for over 15 years now - see that last few paragraphs at www.losttreasure.com from 2005. Most people consider depth to be problem number one, but for many areas target masking is by far the more serious issue. Until detectors can actually see through trash instead of blocking it out, even the smallest surface trash can and will block deeper adjacent items from being detected. Superb discrimination only gets you so far and ultimately the only solution is to remove the surface trash to see what lurks below. The only real limitation we face in this regard is in areas sensitive to digging holes of any sort, like a well groomed park. Even there, slow careful extraction of surface trash over time can reveal old coins missed by others for decades. Beneath The Mask by Thomas Dankowski

-

I'm sure most of you have seen that the price of some of the greatest detectors are under a thousand. The major ones have keep the price between 7 and 8 hundred with some less. This is all good news for us the buyer. For what I see I'm not getting something less in the detector but more for my money. I think detector companies know it's more of us out there that is willing and can afford 8 hundred are less. With the higher number of sales because of the lower price they'll make more money in the long run. That's my opinion but I want to know yours. Chuck

-

Perhaps of interest, a place to collect info of detectors from our past and their modifications. There were a few homegrown detectors about in the 80`s in OZ, their manufacturers no longer operating, perhaps also were others throughout the world, these were "the building blocks" of the sophisticated machines we use now. Some like the Goldseekers 12000 which lead to ML, and another that enjoyed some popularity was the Bridgewright. This photo is of a Bounty Hunter RB10 that has a added pot on the front near coil plug, I believe this modification may have come from not yet ML technicians back around 83-84, unfortunately I`ve lost the operator instructions which had a extra page explaining the use of this pot in GBing the detector.

-

What we are discussing is usually called "Recovery Speed" by most manufacturers. From the White's XLT User Manual: "Recovery Speed - Speeds target responses, so several targets that are close together can each respond. When a metal is detected, it takes a fraction of a second for the detector to process the signal before it can respond to another metal target nearby. The time it takes to process the first metal target signal so that the second metal target signal can respond is called RECOVERY SPEED. There are advantages and disadvantages to fast (high numbers) and slow (low numbers) RECOVERY SPEEDS. Faster RECOVERY SPEEDs work well in high trash areas. However, they will have some difficulties with very deep targets as well as double responses on shallow targets. Slower RECOVERY SPEEDs do not work very well in high trash areas. However, they will have better responses on very deep targets. Slower speeds also have more definitive discrimination sounds. A custom setting needs to be found that suits the preferences of the individual and the conditions in the area. As a general rule, the closer together the metal targets are in an area, the faster the recovery speed should be. The more spacing between targets, the slower the speed should be. Don't use the fast speed if you don't need to. In very trashy areas it is recommended to switch to a loop smaller in size than the standard 9.5 inch black loop. Smaller loops offer better separation between targets. However, larger loops detect deeper and cover more area with each pass. RECOVERY SPEED combined with a smaller loop can be used to search severely trashy areas." Just to confuse people White's decided to call it "Recovery Delay" on the V3i. A low recovery delay equates to a fast recovery speed. From the White's V3i User Manual: "Recovery Delay - 1 – 200 200 = slowest. Additional and separate (beyond filtration) selection for the signal response time. Short response time benefits performance in high trash by providing better target separation. A longer response time allows a larger window to detect deeper targets. Ideal Recovery Delay is dependent on Ground Filter selection, ground mineralization, trash density, and your average sweep speed (how quickly you move the search coil)." It would seem detector manufacturers abhor standard terminology, even the same manufacturer! XP has decided to call Recovery Speed by an even newer term - Reactivity. From the Deus User Manual:

-

Squeezed in a few hours this afternoon to complete a neat Pi project, the Pistol Probe. Also want to take the time to thank Gary Storm of Detector Pro for creating the Pistol Probe, Thank you Gary the pistol probe is one powerful pi. And Finnfoto for encouraging me to finish the neat gadget, thanks finnfoto! Well, Here it is the Pistol Probe converted into a pi detector. Yet, Retains the probe usage with adding back the Probe portion.... Was trying to retain the cool Pistol Probe appearance yet be able to shorten it up a little, hacked off the original Probe portion and added a connector. Using a Uniprobe probe stem allowed the project to work, just remove the Probe and connect the 10" 15us pi coil for pi detection.Was comparing this project with my HH Pi, both air tested the same and with the GrayGhost headset audio bangs out loud and clear. Only portion I hated was using an 1/8" headphone plug, had too no room for a regular size plug. None the less it may be the perfect solution, small yet effective allowing the GrayGhost headset to plug in. Three ways to use this, mounted on the S-handle, or hip mount inside a pouch or auctally it's small enough to fasten to the outer headset band if one wants to wade deep in water. Tomorrow, Sometime in the afternoon will hit a dry river bed. Should do well since both the Pistol Probe and HH Pi share the same 15us circuitry. Could have chopped it up into a smaller version, but that would destroy the neat Pistol Probe appearance. This was important, Maintain the neat stock appearance. I'll share tomorrows finds, thanks for taking a peek. Paul

-

In most industries electronics folks get access to developers kits to build in their own tools and special features. By the time a product goes to market all of this control is stripped out to simplify the unit for general users, who are not usually experienced enough to use it. I was thinking why dont metal detector companies release two versions of code? One for beginners and another set for expert users. It would be easy i would think to pay a fee, get a key to plug in, else reprogram the units for a fee and get all the control i would ever need to work around any issue, gnd, etc out there. I am curious if other folks would like this and would pay for it?

-

Many of the top brand detecting manufacturers offering vdi number displays to narrow down the identification of various targets. Those vdi numbers or specific target identity numbers allow us decide weather or not we choose to dig that specific target. Has anyone found the best way to identify tin from other non ferrous targets? In my experience with disc modes primarily using the mxt I recall most iron targets will grunt and give you a negative number. Non ferrous....copper, brass , gold , a low to med number and silver up in the high 80's. I find tin to be the most troublesome of all metals, it's pretty easy to eliminate most iron targets such as nails, small wires and other odd ferrous objects in disc modes when hunting gold, but pieces of tin. I am just wondering which detector out their today would give us the best tin target id...

-

Recent thread about metal in Penguin, reminds me of a few years back. Local Stock Squad (Cattle Police) were experiencing a rash of horses and cattle being shot. For Court evidence they required the bullets and spent cartridges, so they would grab me and off I`d go with them. To cut a long series of stories short, that went on for a few years until the young "Rambos" were caught. One particular beast, couldn`t find any cartridges but there was a big signal in the cow, on cutting open we found remains of a lead acid battery in the stomach. Cattle station owner found that the beast must have for, whatever reason, decided to eat through the pile of discarded vehicle batteries behind shed. Perhaps of further interest, I found in detecting over stock bodies the VLFs were much better then the PIs, the Pi with 18" coil was tops for finding the spent cartridges but couldn`t ground handle the "chemistry" of the bodies. Not having heard from the Stock Squad for many years, I assume they have purchased detectors for this purpose.

-

I thought I would see how much pinpoint and depth is actually used with different detectorist. or are these features even needed for every day detecting. maybe without them, manufactors could even cut the cost alittle. personally, I have rarely ever used these features. most anyone, including myself have developed an eye to coil coordination and usually are near spot on when digging out a target. even after awhile a novice detectorist seems to develop this skill. after that pinpointing just seems to slow you down. and for depth, is it really necessary to know how deep your target is. maybe it is needed, maybe not. and for some detectors including the fors line. the button does bother some. it kinda cuts down on your options of how you can hold the joystick. anyway it would be interesting to see what other detectorist think, and their uses for these features. or are they a real deal breaker in considering a detector purchase.

-

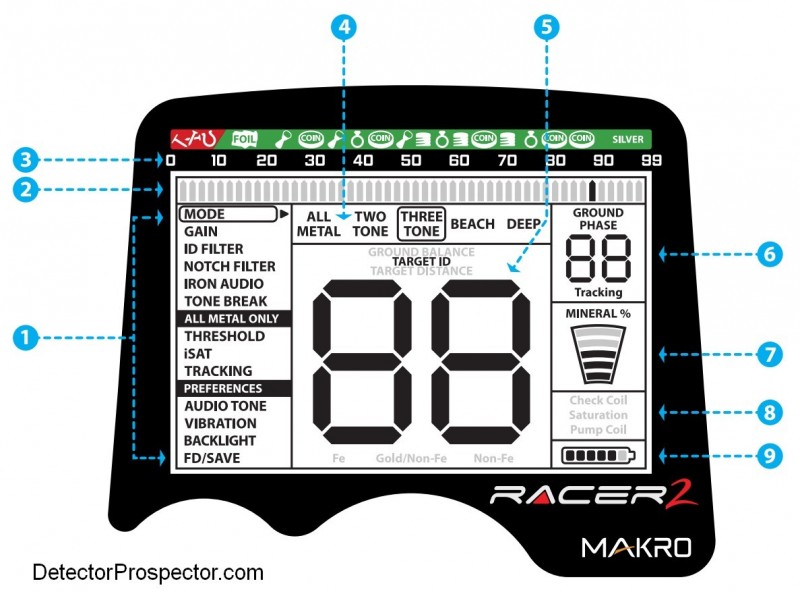

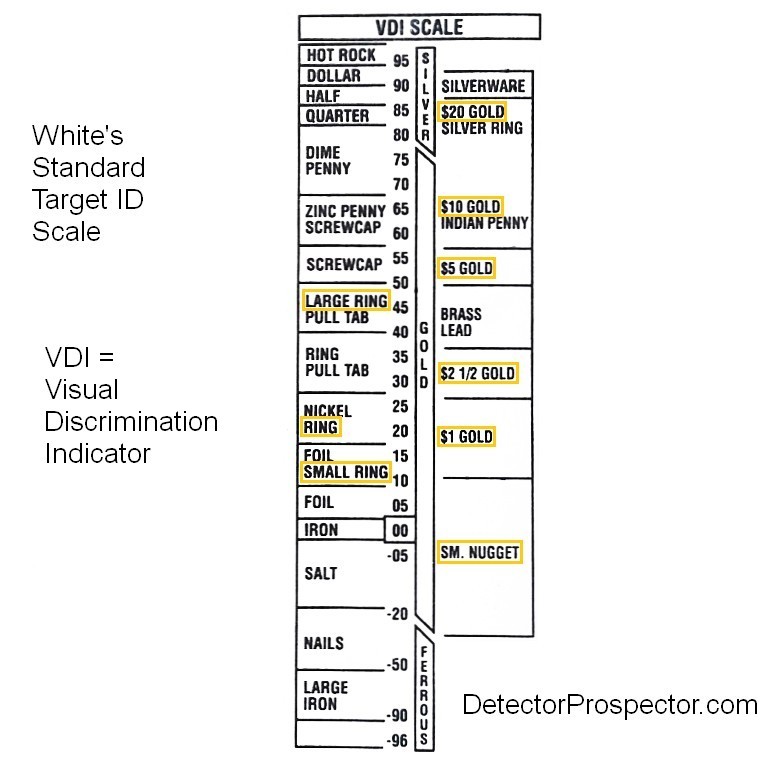

I have used many metal detectors over the years, and right now I have to say that the new Makro Racer 2 has perhaps the easiest to understand, best laid out, most practical display and menu system I have ever seen in a top end detector. Now, you can sure say you hunt by ear and do not need a screen and I get that, but if we are going to put a screen on a detector, then let's do it right. Simple detectors with few functions are easy to make screens for - there is not much you need. But even then just the basics are often wrong. Machines that feature target id numbers, what is the thing you will most look at on screen? The target id numbers! Yet these are often way too small or off to the side as if an afterthought. The Makro Racer 2 id numbers are huge, much larger than on the original Racer and Gold Racer, which are already good sized. The number 88 display in the diagram above is fully 1.5" x 1.5" in size in real life. Other machines have some pretty big numbers but I think this sets a record as I can't think of any machine with larger id numbers on screen though some are close. Makro Racer 2 LCD display and controls Makro Racer 2 screen layout Makro Racer 2 screen and control descriptions The number can be the ground balance number, target id, or depth reading. You get a text display just above the number confirming which it is. Below the numbers are three zone references, Fe, Gold/Non-FE, and Non-Fe, that are used to set tone breaks and audio for the three main zones or bins as they are sometimes called. Another basic feature lacking on a lot of machines - the meter backlight. With the Racer 2 you get off, intermittent, or full time backlighting, and it includes the translucent red control buttons. The control ranges between 0-5 and C1-C5. At 0 level, the keypad and display backlight are off. When set between 1-5, they light up only for a short period of time when a target is detected or while navigating the menu and then it goes off. At C1-C5 levels, the keypad and display will light up constantly. I do not know of anyone doing a better backlight. The right side of the meter is informational - ground phase (ground balance number), mineral % (ground magnetite content), coil warning notices, and a six segment battery meter. Across the top below the 0 - 99 reference sticker, is a series of 50 "bullets" each of which covers 2 target id numbers. Open bullets (which appear gray in the diagram but are invisible in real life - see top photo) indicate accepted target id numbers. Blacked out segments show what discrimination and notch setting you have programmed in a single quick glance. When a target is detected, the big number on the display will be mirrored by one or more of the bullets flashing dark. The four control buttons are simple as can be - up and down takes you through the left hand menu area. Right or left lets you set each function selected by going up and down. The menu is basically the entire feature list just laid out right there for you to see. You want to know what this machine can do, just look at the screen. Most other machines you have no clue without reading the owners manual or at least pushing buttons to see what functions appear. Some settings like the backlight are system wide for all modes. All other settings like Gain are independent in each mode, and can be saved independently in each mode. This means you can play neat tricks like setting up a couple modes with dramatically different settings and then flip back and forth easily between two modes for target checking. You even get to decide what mode is the default start up mode. The Racer 2 starts up in the last mode where the save function was performed. If you always want to start in Beach mode, just modify and save something in Beach mode. Next time you start the detector, you will be in Beach mode. It is simple. It makes sense. No cryptic abbreviations or acronyms. No sub menus. It is, in metal detector terms, a work of art. Whoever designed this should sign it so I can frame it and hang it on my wall.

-

This could be an exciting development for prospectors if the cost is something most of us could afford. "Instead of a pan and a pick ax, prospectors of the future might seek gold with a hand-held biosensor that uses a component of DNA to detect traces of the element in water. The gold sensor is the latest in a series of metal-detecting biosensors under development by Rebecca Lai, an associate professor of chemistry at the University of Nebraska-Lincoln. Other sensors at various stages of development detect mercury, silver or platinum. Similar technology could be used to find cadmium, lead, arsenic, or other metals and metalloids." Read more at: http://phys.org/news/2016-02-hand-held-gold-sensor.html#jCp

-

For years I didn't think about frequency and I still don't spend a lot of time thinking about it now. I know over time the powers that be have found one frequency over another will detect small gold. Oh I'm all for their endeavor. The thing is I've been a coin hunter lots longer than a nugget hunter. That single frequency has found me untold rings and coin back to the early 18 hundreds. Now here soon White's MX Sport Waterproof single frequency detector will hit the market. My thinking is why not it's been good to me all the years I've been swinging a single frequency detector. I know now we have detectors that can run in more than one frequency but do I really need it. I'd like to hear your thinking on this subject. Chuck

-

Abstract Metal detectors are basic tools used in humanitarian demining throughout the world. Because of the importance of these instruments, a document has been produced with broad international support that standardizes the testing of metal detectors. This document was produced by CEN Workshop 7 and is known as a CEN Workshop Agreement (CWA 14747). In particular, tests for determining detection capability are specified. Some soils have magnetic properties that can influence metal detectors, causing them to alarm when no metal is present. This is one of the main factors limiting the effectiveness of metal detectors in some mined areas of the world. Many modern detectors incorporate techniques that allow the detector to reject the effects of the ground while maintaining metal detection capability. An important test in CWA 14747 is to determine the effect of problematic soils on a detector and the effectiveness of any such "ground compensation" function. JRC is engaged in a metal detector testing programme and already has some magnetic soil on which to perform tests. However, a further soil was required that better represents the problematic soils found in many parts of the world. A soil was required with a high frequency-dependent magnetic susceptibility. Using existing knowledge about the relationship between soil magnetism and other soil properties, areas in Italy that were likely to have soils with the required properties were predicted. Zones were identified based on ecopedological and geological maps. Several areas investigated were in Tuscany. Using further local information from the Tuscan Regional soil science service, more precise locations were identified. A brief field survey confirmed the locations where the appropriate "Terra Rossa" soil could be found. A large container of the soil (~1m3) was then transported to the JRC facilities at Ispra where it was installed in a soil test box. The soil in this box proves to have ideal properties for testing the detection capability of detectors in soil. To read the rest see Identifying and Obtaining Soil for Metal-Detector Testing For en extremely detailed report on testing methods and results with several metal detectors see Systematic Test & Evaluation of Metal Detectors

.thumb.jpg.77e4cb5bf39d44bdd2050d2edb7dfdb1.jpg)