Search the Community

Showing results for tags 'gold dredging'.

-

I got tired of my almost completely homemade small dredge, constant floatation issues, got rid of my floation setup and sprang for 48 x 9 x9 factory dredge floats from DNK Prospecting in Oregon, but after they got here, I realized I needed a frame to make all the parts go together, as in engine,floats, sluice, etc..DNK had no frame unless custom built so I elected to try to build my own with 1/2 inch square steel tubing and rivets for now. I had to use 1/2 inch as nothing larger would fit where the frame attaches to the slots in the top of the pontoons. I seem to have misplaced the aluminum caps I was sposed to use to hold the frame to the 6 mounting pads but had a sudden brainstorm. I really wanted a quick frame on/off setup so as not to have to mess with 36 sheet metal screws with the factory setup !! I got a 12 inch long drill bit from Menards and carefully drilled 1/4 inch holes thru the pontoon frame support ribs and made up some 1/4 inch diameter aluminum rods and pins. Now, I can remove the frame with just 4 pins and still have good frame support. So, I need to know where to mount the engine/pump support platform? It is currently over top of the sluice header but still allows reasonable access to see whats on /under my punch plate. I will be using a Keene P90, 2.5 horse pump, 2 inch nozzle, and will point all the hoses out the back to avoid side to side weight issues when running my suction nozzle. I was also told to make the sluice adjustable to get more pitch by sliding it forward if needed? So, I used 1 x 2 inch slotted aluminum angle to make this happen,welded to 2 subframe U shaped pieces and have a permanent 2.5 inch angle on the sluice for starters. I shortened the Keene Jet Tube as it was too long for the space available in my Subaru Forester. Now I can easily attach a quick coupler Keene custom made for me and just quick clip the hose to the dredge. I'd like to have some carry handles or rails, any suggestions? I bought some 2 x 2 inch steel gusset triangles off Ebay to add support to the engine platform legs via welding. I am experimenting with no riffles this time, in favor of heavy duty raised expanded steel about 3/8 inch thick x 2 feet long with backed miners mosss underneath. I also raised the header 3/4 inch above the sluice box floor to try to get less turbulence,added some raised 1/4 inch hole punch plate and foot long section of Keene Miracle mat in the 1st 12 inches of the sluice as well, another experiment... -Tom

-

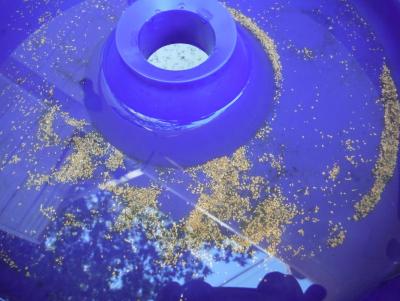

Hey Steve, Just finishing up my gold dredging season and catching up on your Alaskan trip. What a great story...went through all pages. Nice gold too! Good job man! That is a tough way to get gold - but almost more satisfying due to the effort you have to go through to get it. Here are some pics of my dredge season and gold. My mining partner and I got 31 oz's of beautiful Oregon gold! I got just under half of the take... Couple pics of a bonaza Le Trap sluice cleanup, and nice blue bowl cons and me at lunch atop my dredge (shore was too far to get back to until end of day, dragging the dredge back under water 150 feet to shore). My detecting season starts now! - hope to get some nice detecting nuggets like yours! Take care, Alan

-

So I have this idea to build a 4 inch sub surface dredge. I have all the parts and pieces with the exception of the pump and moter (in route). Well spring fever is kicking in and I plan to assemble this dredge. I am currently engineering the frame work. My question here is all the pictures I have seen show the dredge tube dead center in between the floats and looks to be level with the floats. Should the tube be suspended lower in the water or submerged completely? Just for reference the setup consists of. 1. Keene 4 inch tube. 2. 15 foot of 4 inch suction hose. 3. 4 inch nozzle. 5. 20 foot 2 inch pressure line. Hard line not lay flat. 6. Keene 3 inch mini floats. 7. Keene P180 Pump and a Kohler Command Pro 7 hp motor. 8. No air on this one. 9. 1 inch box aluminum frame work. Also I found a great deal on a Hydro Force nozzle. Anyone have any thoughts on these?

-

I was involved in some validity exam testing on some mining claims in Alaska a few years ago. Short story is samples had to be taken at various locations to prove the claims have paying quantities of gold. Any claims not passing the exam would be lost. This photo was taken on Skookum Gulch in the Wrangell Mountains of Alaska. It is a small short drainage but was very rich at one time. It was mined out by hand as the stacked rocks reveal but some gold still remains. In this case we used a Keene 175-30 highbanker / dredge combo for the test work. The creek is very small and so had to be ponded up for the system to work, and it used nearly all the water in the creek while operating. The little gulch almost goes dry later in the season. One interesting note is that we left the highbanker stored upright over the winter. Water entered the tops of the leveling legs, which are hollow steel tubes with feet welded on the bottom. The water froze over the winter, and because the legs were stowed in there shortest configuration it proved impossible to extend a couple of them. And believe me there was a lot of squeezing in a vice and pounding of hammers involved! The metal had warped out to the point it was impossible to squash back down small enough to pass through the bracket hole. We just gave up and jury rigged this little saw horse and fence post system you see here. The legs were later replaced and drain holes drilled at the bottom of all the legs to allow them to drain in the future to prevent this from happening. The amount of gold found was marginal and last I heard the disposition of this particular claim was in question. It was a fun project though and a nice photo of how a highbanker / dredge combo can be put to use.

-

I visited Ganes Creek, Alaska many times over the years. This was always to metal detect for gold in my case. However, there were others who wanted to suction dredge while at Ganes Creek. My friend Brian Berkhahn was one of them. Brian just loves dredging. Detecting he is good at but has less patience for. So in 2002 while we were at Ganes on a nugget hunt Brian talked Doug into letting him use a 5" Keene dredge they had at the mine. There was a drainage ditch upstream where several large nuggets had been found in the pile of material dug out of the ditch. I was a bit skeptical as the nuggets in the tailings are few and far between, but Brian wanted to give it a go. As I recall he did not find much here, but he does have the distinction of being one of the few guys who have done some dredging at Ganes Creek. He is on the forum so maybe he will chime in with his recollections on this photo.