GoodAmount

-

Posts

59 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Posts posted by GoodAmount

-

-

I’d put my bets on VLF-like multi frequency/6000-Geosense approach, but with multiple concurrent ZVT timings plus Algo-like discrimination. You can be guaranteed Minelab will have developed highly complex algorithms to match the capacity of current chipsets to get the most out of the machine in deep, hot, variable ground. I wouldn’t even mind if it was heavier than the Algo or 6000. I’d be surprised (and disappointed) if the 8000 doesn’t reinvigorate old patches and open new ground like the Equinox 800 did for relics, coins and small-gold hunting.

-

On 2/26/2024 at 12:11 PM, grumpy said:

hi good amount

if you are using old leaf spring and you do not destress and anneal it before welding it

is usually not a good idea to weld across the face of the tine as it can create a shear point just blow or above the weld

leave the old point on the pick, shorten it and taper it to fit neat with the new point on top/or below the old point and only weld the sides not the face

you could leave 2 or 3 inches of the old pick point to weld the new one to

Yep, you’re right. I didn’t weld it straight across though (see previous post).

If I was doing repairs as a business for customers, I’d be sure to go through a rigorous process, but given my pick is a big DIY experiment anyway, I’m happy to leave the result in the lap of the gods. Plus, I’ll just make another one if it breaks. I’ll be surprised if it does though - it feels pretty robust. -

On 2/26/2024 at 8:26 AM, GotAU? said:

That looks like some great work. I’m trying to figure out how you welded that on and then ground it down so smoothly, did you weld with a gap between the two parts?

The tip of my pick was already a bit of a stub so I ground it down to a V profile and matched the back end of the new tip to suit. I figure by adding more surface area to the join perpendicular to the sheer line it’ll give it a bit more strength. There was no gap between parts, but I beveled the edges to give the weld some bite. So far so good - I’ve been out with it a few times since and the tip is holding up super well and keeping its edge.

-

I didn’t quench or temper the one shown in the picture. The source of the welding heat was away from the tip, so I didn’t worry about it. I’m happy to just see how it goes and if I’m having difficulty keeping a keen edge I’ll just weld on another tip and spend some time hardening and tempering it.

-

1 hour ago, Jin said:

I've been thinking about whether to weld it on or bolt it on like another pick I saw with replaceable ends. For the hassle though, I'll probably end up buying another Gold Digger pick - Looks like Nenad (phasetechnical) sells them

Gold Digger picks are awesome. Those Supersede picks are awesome too - I love that the parts bolt on and are replaceable (I’ve done the same thing with my DIY-build pick an it’s worked out super well). I’d recommend welding on a new tip if you’re only replacing the sharp end of the tooth, given bolting it on will interfere with its travel into the ground. Bolting an entire new tooth at the handle collar will work great, but you’ll be throwing away good steel in the process.

-

Honing down a triangular pick head can be laborious if you’re wanting to maintain its triangular shape. I’ve just retipped my pick with a new section of carbon steel from a trailer leaf spring. It was getting pretty stubby in the tooth and becoming difficult to get through the ground, particularly when hunting heavily surfaced areas where you need to bust up slaty bedrock. In those situations it needs a well honed point and a decent wedge profile to break up the rock without sending it flying. I welded on a small arbitrary 60x18mm parallel-edged tip section and ground a relatively oblique taper on the end with an angle grinder. I reckon I’ll get a year or so of easy regrinds to maintain its shape before needing to replace it again. I took it out for a test run two days ago and it sure rips through slaty bedrock like a champ. It’s slightly too long in the tooth at the moment, but it’ll only be a couple of sharpens before it’s the right length.

-

I use rubber ties like these (thanks to Howard of QED fame). They’re grippy, easily removed and reusable.

-

17 hours ago, jasong said:

On your slicer do you just do solid with no infill? What nozzle and layer thicknesses out of curiosity?

I’m doing a solid infill, but it’s never quite solid given the extrusion profile is circular and there’s gaps between strings. It’s possible to over-extrude material to reduce the gaps, but I’m using a Stratasys machine/slicer that doesn’t give me that option. Printing parts ‘airy’ is good for keeping their weight down though.

My nozzle diameter is the standard 0.4mm and layer height is 0.25mm.

I’m super interested to hear how you go. And yes, bring on the Star Trek replicator. 👍

-

@jasong Amazing Goo is a good lightweight option. Do you just apply it around the rim? I’ve seen it done like this, but the centre of the coil housing still gets pretty scuffed up.

Annealing in salt is a great idea. I might give that a go before trying hot water - I think it’ll maintain shape integrity better.

I went out for a swing this morning with a fresh skid plate on to a spot where it would get a hammering on bedrock. Below are pics of how it looked after the session (I did reasonably well 🙂). I’ll track the rate of wear and see how long it lasts over the next few weeks - I’ll be heading out most days, so it’ll rack up hours quickly. I think with the extra material thickness around the leading edge it’ll last longer than a styrene vac formed part, but not sure how it will compare to an abs-pc mix equivalent. Regardless, I can just print another one for a fraction of the price if it does wear out fast. 👍

-

…just don’t use cloth tape - it will leave adhesive on your coil when it comes time to replace it.

-

1 hour ago, fourtyniner said:

It would be great if someone came up with a coil top cover to protect it from scratches from the scoop. Does anyone have any ideas on what to use to protect the coil top?

I just use pvc duct tape (pictured in my earlier post in thread). Works a treat.

-

12 hours ago, jasong said:

@GoodAmount Does it help the cover stay on if you angle the vertical edges in towards the coil some small amount like 0.5 or 1mm to keep the edges on the coil in tension?

A solid TPU skid plate might be interesting too - it's flexible so you could angle the lip in quite a lot or put a locking ridge on the top, and pop it over a coil with no tape at all - just like a cell phone case. And it would be way quieter to detect with. TPU is tough enough that it would be interesting to get rid of the skid plate altogether and see if just a layer of it on the sides and bottom of a coil would be sufficient. I think I could actually print a layer onto existing coil bottoms with some kind of glue or bonding agent, too bad the sides aren't really doable.

Watching some vids on it last night, I think oven/water annealing might get a 3d printed coil to closer to the same toughness as a vacuum formed or injection molded. Between that and a good material selection, I'm thinking now it's probably possible to make an equal if not better coil housing/skid (in some cases) on a 3d printer than the commercially available ones if done with annealing and using tough plastics.

You could certainly play with the angle of the lip to give the skid plate a tight fit. Or just globally scale the whole part for a tight fit according to the extrusion tolerances of your 3D printer. The coil housing will have a bit of draft on it anyway, so given there’s a perpendicular inner wall on the skid plate file, it will have the same effect. I’ve uploaded the stl btw if you want to mess around with it.

I love the idea of a flexible skid plate that lips up over the top of the coil like a sock. I’ve never had much luck printing TPU though - it’s very temperature sensitive and I end up with either a globby mess if it’s too hot or a part that delaminates easily if not hot enough. Getting the right balance is tricky. I’ve been wanting to design a two-part clam shell version where the top shell protects the top of the coil cover when scraping the scoop over it, but I was planning to just make it out of ABS. A flexible one would be great though.

I usually anneal parts with a heat gun, but it’s better to do it in a more controlled way. I’ve had a few disasters where I’ve melted parts in the oven beyond recovery, so I’m reluctant to do it that way until I have an industrial oven with better temperature control. I haven’t tried hot water - I’ll give it a go. 🙂

-

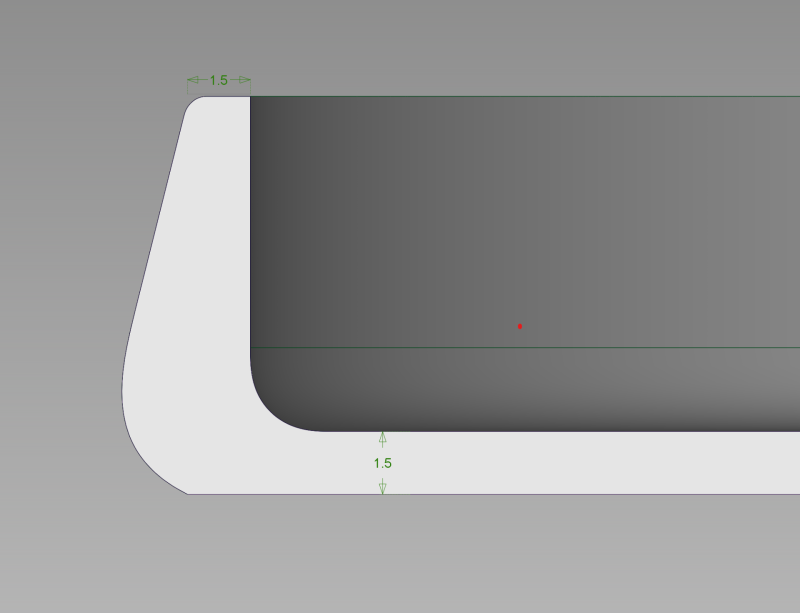

This is the profile section I'm currently using, working on the premise that I can 3D print plastic volume where I need it and taper it down where not required. This means I can reduce overall weight while increasing wearability. 3D prints are inherently lighter anyway as the density of plastic is reduced given there's micro air gaps between the extrusion lines, whereas a typical vac-formed part comes from a 'solid' sheet of material.

I've been finding if the fillet on the leading edge is too small it catches on rocks, so I've left it fairly generous. For printability, I've had to leave an intersection between the base and the leading edge for better printability, but it doesn't seem to catch on rocks much and it smooths off relatively quickly. I'm testing a few different profiles to see if I can get lighter weight and better performance for both for wear longevity and slipperiness through the terrain. I'd be interested in your thoughts - I'll add an stl to the downloads section for anyone to try.

-

5 minutes ago, jasong said:

Does it seem like the coil body itself is some burlier plastic? I have one I can try to burn and sniff but I'm a bit hesitant haha. But I think you are right on the styrene for the skid plate.

Did you have any issues with layer adhesion using the ABS over time?

I’m not game to burn/sniff the coil housing either. 🙂

I haven’t had any troubles with layer adhesion in use. Skidding it around on rocky ground smooths the layers out pretty quickly and so far I haven’t had any layer splitting. But I’ve been adding a bit of meat around the wear surfaces on the rim to increase longevity, so that will also strengthen the part. The only trouble with ABS is that with large surface area parts it wants to warp and peel off the build platform, so you’ll need a heated chamber. Mine chamber heats to 75 deg.

PETG should work well though, and doesn’t warp as much.

-

I just did a burn/sniff test with an old Sadie skid plate and it smells like styrene. I’ve been 3D printing replacements in ABS though and it works really well.

-

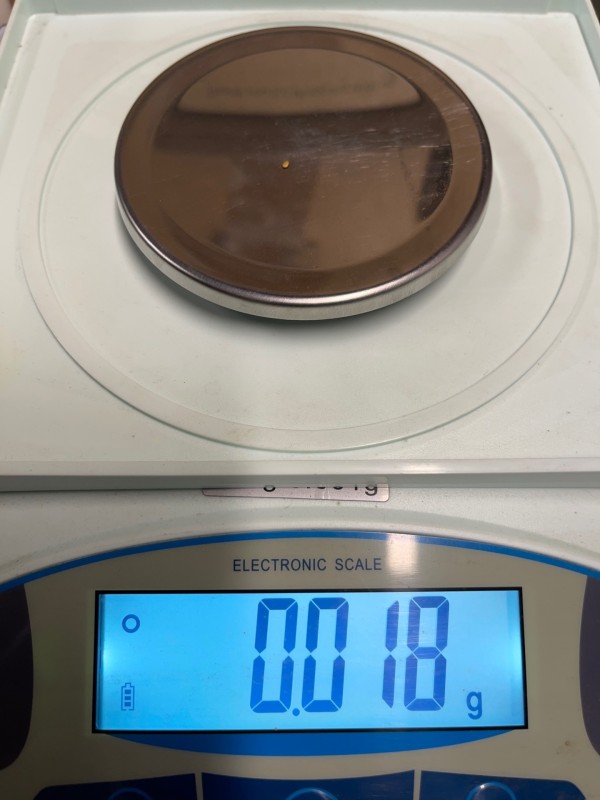

This is what I’m finding with the 7000 + X-Coils too. I’ve been working in Difficult (smoothing off) to remove some of the sensitivity to hot rocks and upping the sensitivity to max so it runs super noisy, then raise the threshold to clean up the variability in the audio. This can mean running as high as the 35 to smooth things out, but mostly around 30. The high threshold itself still rises/falls over tiny targets, usually with a longer/different response than the surrounding ground-noise signal. I’m consistently hitting specs between 0.01 - 0.02g this way, some of them on edge in shale bedrock. My gold finds have markedly increased with this approach over using Normal at reduced sensitivity, as it cuts through the ground noise better. It sounds like the ATX might be similar in this respect.

(…sometimes when the ground is too variable for Difficult I’ve been pushing the machine into Severe with the same high-threshold approach and can still pull the tiny stuff. Severe is a much underutilized timing on the 7000, but I’ve found it can still be super sensitive to tiny specs when coupled with a small X-Coils coil.)

-

I’m regularly picking up specs in the Central Vic goldfields between 0.01-0.02g at 1-2 inches with the 7000 + 8” X-Coils in HY/difficult/sens18-20/ths30 (variable ground in my area masks tiny stuff in normal), but it certainly won’t pay the bills. Hoovering up the tiny stuff is fun for a while, but gets old pretty quick if that’s all you’re finding. It’s a relief to hit on a target that’s bigger and deeper even if it turns out to be a bit of trash. The little ones often lead to the bigger ones though, so it’ll be interesting to hear how the E1500 transitions across the spectrum of tiny specs to bigger-deeper stuff in variable ground. For the price/weight/ergonomics, it sure seems like a bargain.

-

16 hours ago, phrunt said:

It's a concern you had EMI problems as that's where the QED really excelled for me. It worked remarkably well even right under power lines. I believe one of the problems people had been was EMI related which sending the machine in for repair fixed. You'll see I'm on gain of 10 (max) right next to the power line.

Thanks for linking your videos phrunt. It looks like your machine was much quieter than mine. I used headphones most of the time, which seemed to amplify the problem. On some occasions in a couple of locations the EMI spikes were so frequent and strong I had to quit detecting. I ended up buying one of Woody’s in-line filters, which made it usable at those times. My machine also had a ground balancing issue which turned out to be a dry-solder-joint on the main circuit board. Service was excellent to get it repaired quickly.

I didn’t send the machine in for a firmware upgrade after reading about yours and others experiences with sensitivity a depth reduction. I’m glad I didn’t. My Sadie coil pretty much lived on it full time and the smallest flake I found with it was 0.08g pretty close to the surface. I was proud of the achievement at the time, but with my 7000 + X-Coil combo I’m now regularly hitting gold that size at depth and frequently below 0.02g. In many locations in my area this represents the majority of gold left, so it can be the difference between going home with a few bits in my pocket or getting skunked.

I don’t get to the beach often, but when I do I’ve been using my Nox 900. I’m very keen to use the QED next time I go now.

-

I cut my gold prospecting teeth on a QED PL3 after battling the mineralised ground of the Golden Triangle in Vic Aus with a Whites VX3 for 9 months. I found my first gold nugget with the QED, so it holds a special place in my heart and I don’t think I’ll ever sell it.

All the comments above mirror my experiences, and while I went on to find just over an ounce of gold with it (more than paying for itself), it was hard going and I’m relieved to now be using a 7000. I was able to keep up with my prospecting buddy on the small gold when he was swinging a 5000, but when he got a 6000 he left me for dead.

I love the fact that a one-person company could develop a machine that costs a third of the competition’s machines and keep up with them functionally (to a point). I also love the idea that he could 3D print many of the detector’s parts at home, bypassing the investment risks of tooling up for mass production and keeping the production system agile. And cost effective. When one of my parts broke, he was also willing to send me the digital files so that I could 3D print my own replacements at home - which is an amazing difference to the attitudes of the competition.

The PLA+ plastic he uses is the wrong type for its application - it’s not that it’s cheaper than other plastics, it’s that the thermal characteristics are just not meant for high temperature conditions like being left in a car on a hot day. It’s a bio plastic and I celebrate its sustainability credentials, just not at the expense of product robustness and performance.

My machine suffered from EMI issues and didn’t handle variable ground vey well, which made for noisy detecting. It was tiring to listen to and I had to concentrate hard to hear faint signals, but I think it made me a better detectorist in the long run. I value my experience with the QED on the goldfields, but now that it’s been retired from those duties I’m interested to see how it goes on the beach.

-

16 hours ago, Steve Herschbach said:

That's simply not true. I think the X-Coil is one of the best things that ever happened to 7000 owners, and have friends that love them. They proved what the 7000 was capable of if Minelab had ever truly gave us coil support on the model. My issue was simply disclosure. The risk of the modification being done was totally downplayed initially and people with concerns where treated as if they were irrationally concerned over nothing. Yet I know a guy that blew up two 7000s at huge expense. So yeah, the risks were real. Now, it seems to be under control as better adapters have come about.

To repeat, I think X-Coil did a huge service by producing the coils they have. My only issue was with proper disclosure of the risks involved, which I believe were downplayed initially. And even that really is not on X-Coil as they really don't communicate directly. Nope, nothing but respect for them, and even wish they were running the coil show at Minelab.

But do I think X-Coil has kept GPZ 7000 users on board when they might otherwise not be? Not really, because I truly believe that a GPZ 7000 with a stock coil is still the best detector option available for getting all the gold possible in a single pass over an area. That is why people use it. A GPX 5000 can hold it's own on the big solid stuff with the 7000 but the 7000 will kill it on specimen gold, no matter how many mods you do. A 6000 hits specimen and smaller gold only marginally better than a 7000, and as you note simply putting an X-Coil on it is enough to bring the 7000 to 6000 levels of performance there. In the end however it is the 7000 ability to punch deeper on big gold than a 6000 that keeps people using the 7000. Do X-Coils help extend the usefulness of the 7000? No doubt about it. But it does not change how I view the machine anyway, which is as the machine to own if you are really serious about wanting to put weight in your pocket. Not numbers - weight. If I have to cover one acre of ground just once, with one machine and one coil, and will never get a shot at that ground again, then I'd pick a GPZ 7000 with a stock coil as being as my best shot at getting the most weight out of the ground in one pass as is possible, both large and small, solid or specimen, but with the emphasis one weight. If a few small bits get missed that not going to matter as much as missing the bigger ones at depth, the real bread and butter that pays the bills.

Gotta admit I don't see anything to do with detecting as right or wrong or ideological. I'm a big fan of just using what works, and anyone thinking they have a corner on knowing exactly what that might be, most especially me, has not been around enough. These things are all just tools and it's about getting to know your tools, and knowing when to use this one or that one. And sometimes that is nothing more than just an educated guess at best. What works in Australia most decidedly will not work in some of my old haunts in Alaska, and that's a fact.

Now after barfing that all out, good idea, I'll mention X-Coil.

Just reflecting on your response to my earlier post. I’ve always thought that in your past posts the subtext to not endorsing cutting off a connector of a Minelab OEM coil to bypass their closed-source software/hardware for aftermarket coils was as a matter of principle. Sorry, my mistake. I totally get that the lack of acknowledgement from X-Coils that a dodgy patch cable will cause irreversible damage to a machine and that it needed to be addressed …and that is principled enough without getting into higher ideological debates around integrity.

BUT, it’s your integrity that anchors me to this forum, and it’s that integrity that has fostered an amazing group of awesome people that can engage in fearless and frank discussions that astonishingly rise above the sometimes-libelous slander some other prospecting forums fall into.

Your detector reviews are important in that mix. I agonised over the decision to spend my hard-earned cash on a GPZ 7000 and could only go by what I was able to read, without physically experiencing the machine for the 100 hours necessary to get to know it. I made the plunge based on your reviews triangulated with countless other posts by you, JP, phrunt, d4g, Lunk, jasong, Aureous to name a few. The mix of your integrity with a long history of well-proven skills breeds a strong sense of trust that is hard to beat.

This forum has been the lifeblood of my prospecting adventures and your reviews are a worthy centerpiece. Looking forward to reading the new ones. 🙂

-

Great clarification! And agreed 👍

-

Steve, I also wonder if there needs to be greater acknowledgement of the impact X-Coils has made on the extended capability of the 7000? I know unsanctioned hacks like these are contentious from an integrity perspective and I completely support an ideological stance on it to this end, but they are now an embedded part of the product ecology and one of the key contributors in keeping the machine in wide circulation and use.

There are many better examples than mine, but last year I stepped up from a QED to a second hand 7000 with a 17x12 X-Coil and immediately more than doubled my gold take. Then with the 8” X-Coil doubled nugget numbers again with the added ability to hit the tiny ones. I’m now quite happily keeping up with my prospecting buddy with his 6000 on small gold. Rightly or wrongly, X-Coils has extended the capability range of the 7000 and I’m wondering if it deserves calling out as a byline in the new review …even if clearly stating that you don’t support it?

-

It really saddens me to hear that. I get taken to another place when I watch his videos. Sometimes it feels like I’m in an art gallery watching a video installation and other times a film festival watching a documentary. His films are very different from all the other YouTube prospecting content and are always compelling and informative. I found the one depicting the life of “Poppy” in particular very poignant and touching. All strength to Joe through his tough times.

-

I’m sad to hear ML has lost the heart for making videos. I learned a lot from watching his channel and enjoyed his vibrant style.

Another channel that may be worth adding to the list is Prospecting 101 For Aussie Gold Nuggets. While production values aren’t as slick as others, holy moly he’s found some gold over the last 40 years and is willing to share how he did it. Very likable and knowledgeable chap and the channel is much more than a beep-dig-and-gloat fest that many others are guilty of.

What Nugget Coils Are Your Most Used / Favorites?

in Detector Prospector Forum

Posted

My favorite detector/coil setup by far is the GPZ with X-Coils 8” - I’ve found many ounces with that little coil. It hits on the tiniest pieces at good depth, but also goes surprisingly deep on larger nuggets. I mostly hunt rocky terrain where the bigger coils I’ve got aren’t maneuverable enough, so they don’t get much of a look in.