-

Posts

270 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Posts posted by FloridaSon

-

-

Thanks everyone

Hope we all have a good 2021.

-

Thanks Chase, thanks Joe D. It has been spotty for the last two years. Even when the weather is right, the Treasure Coast gets stingy with her secrets. Plus all the sand coming next year.

It was a blast.Regards all

-

Watching for several days of strong wind, this time out of the south, not as good as NNE but still stirs the sand and removes some, it just opens and closes quicker.

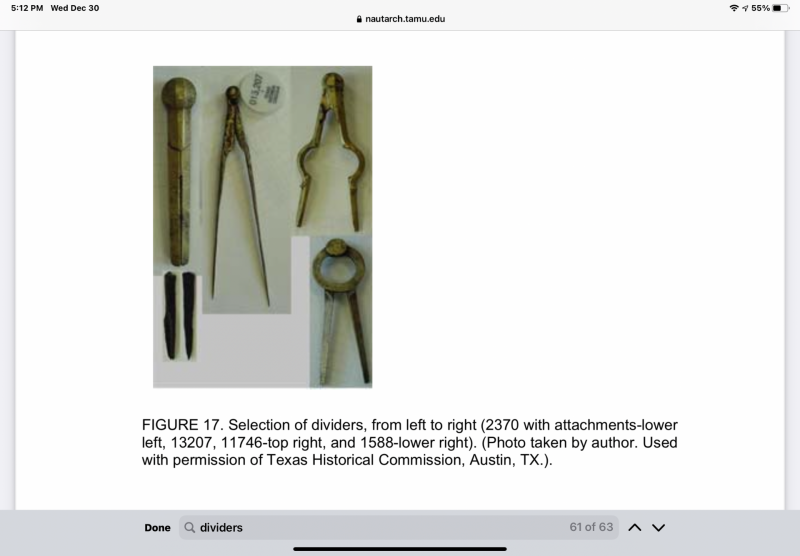

Found two documents one by J. Clausen, archie that worked with state and on several sites including the Winter Beach Survivors camp and a “1715 Treasure Ship”; the other by a private collector, Lou Ullian. https://1715fleetsociety.com/lou-ullian-personal-collection-treasure-photographs/ and finally picture of a restored set.

Happy New Year everyone!

-

On 12/22/2020 at 1:01 PM, phrunt said:

I've been saying this works for some time, glad someone finally tried it and yes it works even better when connected to the ground like Pimento points out.

Manufacturers moved away from the big metal boxes which were good for EMI and into plastic housings and very few did anything to mitigate the EMI that the plastic housing is letting in. A protective cover with a foil type lining would help a little.

First Texas used EMI paint on the T2/F75 connected to ground to help although there are far better technologies now where they can incorporate conductive fibers into the thermoplastics when molding the housing.

Wonder if the foil tape applied in a couple directions might be enough?

-

A more accurate depth indicator or that is not possible just remove it.

-

On 12/20/2020 at 11:28 AM, Joe D. said:

Or else it would have been blasted into the Indian River long ago! 👍👍

I had no idea, thats great ! Thanks so much

-

On 9/23/2020 at 9:36 AM, Joe D. said:

Great way to start Fall here!

Great pictures Joe D.; if you don't mind me asking where are those beach front rocks in the picture? Walton?

This fall has been disappointing and you have not missed much. We need min two days of moderate N NNE winds. The coastline runs NW-SE so even NE winds are straight on shore and we need min. 4-6' high surf as well.

I use the surf reports forecast. Happy Hunting!

-

See other responses below.....Happy hunting!

-

The Triton issue is a good example of bad policy. I agree, and never said a hole dia. change would stop the breakage, just interesting (to me) any change was made but that could just be from a change in outsourcing. I always think of the Ford Pinto exploding gas tanks where it was cheaper to pay a few law suits than recall many times that cost. Not that the total $ or injury are the same. Sick business model. IMO

I would expect Minelab to honor the breakage until warranty expires; after that they would do what any for profit business would. Again, just my view. HH

-

19 hours ago, GB_Amateur said:

So the hole through the coil housing for the mounting bolt has been reduced in size? Previously a nominal 5/16 inch (~8 mm) diameter bolt was included. Are they shipping smaller diameter (~1/4 inch) diameter bolts with these replacement coils?

Not sure it is 1/4" but yes, I believe it is slightly smaller but it may be just a mfg change, not to improve the breakage problem. But if the ears remain the same size and the hole/bolt a little smaller, it would add a bit more plastic to the ears. The new bolt does fit loosely into the ear holes. Who knows, and I am not an engineer.

13 hours ago, TedinVT said:When my coil with both ears broken was replaced this summer it came with a new coil bolt and new coil cover all attached to the coil. Nice. Replacement was very quick. The guys at Ft Bedford are doing a great job.

Yes they are, my new coil was shipped (from Alum Bank) back the same day my old coil arrived with bolt and washers. Plus Dan called me the next day to ask if I had any concerns. Can't ask for more than that.

-

2 hours ago, GB_Amateur said:

There is either a measurement error, a typo, or a conversion (metric <--> SAE) error. 7.15 mm is not equivalent to 0.309 inches.

Thanks. How about 0.281”

-

On 9/11/2020 at 11:38 AM, B0SC0 said:

11" Coil (1 year old)

3.00mm(.1180") ear tab

22.44mm (.8940") between both ear tabsRubber washers (1 year old)

5.00mm (.1970")Thanks Bosco; I took your original measurements since Ii did not think to do that.

Received a new 11" coil today:

Looks like some changes were made.One thing is the clearly seen seam line that falls across the outside of the ear at the bottom of the bolt hole on each ear. I never noticed if the original had this though.

Original bolt dia. at shoulder 8.04mm (0.317")

New coil bolt dia. at shoulder 7.15mm 0.281 inch

The inside hole in each ear measures 8.2mm+_

3.00mm(.1180") ear tab -- NEW coil 3.51mm+-

22.44mm (.8940") between both ear tabs -- NEW coil 22.82mm+-Rubber washers (1 year old)

5.00mm (.1970") -- NEW coil 4.97mm+-The new bolt also had a flash running down both sides that I cleaned out prior to screwing together. I never noticed on the original though.

Since measurements can vary, suggest others check mine as well.

-

-

Nothing will beat those times you spend with Dad! Sounds like a great trip.

-

17 hours ago, midalake said:

. Again, a [solid] plastic coil stiffener is epoxied to the coil. Then a plastic side plate is added to both sides. Each coil ear is now 1/2" thick!

That should solve the weak/flex problem. I have to that.

-

Happy to report Minelab warranty dept is still outstanding. One day after Alum, PA received my coil, they had a new one on the way!

Reading this thread and others, the consensus seems to be:

Happens to inland, beach and water hunters.

Caused by tightening the coil bolt to the point it flexes the ears leading to breakage at a common weak point. That weak point may be caused by the ear being to thin and/or the colder plastic flow when casting the part.

Scoring and scratches on the ear indicate a future problem may be in the works.

Question: Might this be connected to the left/right 'scrubbing' the coil does for hunters that like to keep the coil on the ground? That might cause the break to happen at the mid way weakest point.

Question: Will stiffening the area of breakage lead to a new weak point breaking at a slightly different location?

Question: Is the lower half of the ear thicker than the upper? (Ill check when mine arrives).

💡Just occurred to me that like when using Apple products, we are unwilling testers for this defect. All Minelab need do is read these threads to get enough information for a true fix instead of throwing new coils at the problem. Anyone remember the Ford Pinto fuel tank issue?

Thanks everyone,

-

Yes, they should although some headphones have trouble pairing with the NOX. I do not know for certain.

And have to say, noise canceling is a great thing on the beach to my old ears.

In specs the se7max says: "Wireless: Bluetooth 5.0" does not mention aptx LL - low latency. The ad does mention apt-X, but again not LL (low latency).

I have a noise canceling set of PAAWS Wavesound 3 which I really like. You have to look for the latency information of these headphones. Wavesound 3 says: "aptX LL's lightening fast latency speed of only 34 milliseconds eliminates lagging audio". I cannot find that in the specs link on the se7max phones.

The phones I bought have better sound isolation of outside noise even without noise canceling. You might check that on the se7max.

The 800 included minelab headphones latency is: usually 40ms (per 800 user manual)

You could also plug any headphone into the WM 08 BT module and get 17ms latency.

More: Page 54 NOX user manual:

Wireless Audio Latency

Each EQUINOX compatible wireless technology has a slightly different latency, or delay. When metal detecting, the lowest latency is best.

When the coil is moving across the ground, any delay (latency) of the audio signal means that the coil will have moved past the target that produced that audio. Low latency (less audio delay) causes targets to be detected closer to where they really lie in the ground. This is very evident when swinging a coil left and right across a target. A higher latency will mean that the target is perceived to be in two locations either side of the actual location. A lower latency will minimise this effect.

Wi‑Stream Technology

Wi‑Stream uses efficient low-power digital audio transmission to achieve the non-perceivable audio time lag of 17 ms between EQUINOX and the WM 08 Wireless Module.

For the fastest possible wireless audio, use the WM 08 Wireless Audio Module*.

Qualcomm® aptX™ Low Latency Technology

aptX™ Low Latency technology is faster than standard Bluetooth, with a delay of 40 ms, giving a faster detection response.

Minelab ML 80* headphones use aptX™ Low Latency technology, and will deliver faster audio than standard Bluetooth® headphones.

Bluetooth® Technology

Any standard Bluetooth® headphones or earbuds can be used with an EQUINOX Series detector.

However, Bluetooth® technology has a high audio latency of 100 ms.

This can make it difficult to visualise the exact position of a buried target if you are detecting with a fast swing rate.

Hope this helps.

-

One day after coil rcvd in Alum, PA I was notified a new coil is on the way! Cannot ask for better service

-

Interesting idea, Tom Dankowsky did something like that but sifted the dug soil. It is an interesting read link below. If you are digging it up anyway, dump it into a screen and detect the ground as you planned.

https://www.dankowskidetectors.com/painful_truth.htm

Give it hell.

-

Incredible, thank you

-

I see what you mean, agreed.

-

On 11/2/2020 at 4:11 PM, GB_Amateur said:

So if my measurements are anywhere near correct, both manufacturing tolerance (Equinox washers) and usage wear (X-Terra washers in particular) come into play.

I can see wear between the washers - the whitish areas. Also across the break point. And look in the holes that accept the bolt. So may be a combination of things.

-

18 hours ago, Joe D. said:

FS,

We are not doing anything wrong with our coils! It's a poor design, and/or the poor choice of recipe for their thermoplastic! In a nutshell, the coil ears are too thin and brittle! I'd much rather have the tab's reversed, like the AQ Ltd.! Makes for a much beefier design option!👍👍

True, but 'they' are not going to fix it. My coil is enroute to ML for hopefully replacement. And I want to keep hunting, so I don't mind being proactive a little bit. You make all good points. regards

-

Quote

it does seem more of an issue for water hunters.

...not in my case, beach hunt only but no surf, or in water. Took every precaution including detect-ed washers. I noticed the stock washers were so thin the shaft end rubbed on the ears. They would make the coil creak due to the plastic to plastic rubbing. Thought the thicker detect-ed washers would protect it. After it broke yesterday, when I disassembled the coil from the shaft I noticed grains of white sand between the washers and coil ear bearing surfaces which were scored. Maybe i should have been taking these apart and cleaning them. Don't think silicone and sand would help in my case.

The white areas are wear. So spraying the bolt might help reduce scoring and scraping. The edges of the coil ear are white and may have been cracked before breaking. Man this is all over the place!

I've Been Killing It On Super Deep Silver

in Minelab Equinox Forum

Posted

LOL, perfect description - me too!