-

Posts

779 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Posts posted by Jim in Idaho

-

-

Id just use silicone caulk, or even latex caulk. Doesn't require anything super strong, as long as it sticks.

Jim

-

The stability mod on the big boxes is more electronically complex than the SL mods. Also requires added parts.

Jim

-

22 hours ago, rled2005 said:

Jim, should I fix it myself or send it to the repair guy he n Oregon? He want $50 to look at it, plus parts.

The problem on my first one was a spot on top, to the right of the rod mount. Any ground contact, that pushed the rod to the right, cause a downward pressure on that spot, and caused a signal. I figured I could make a bridge of some sort so the rod would no longer push that spot down. never did it, but Steve at Whites sent the bad one back with the new one, at my request. (they were going out of business anyway). I have not looked into the problem with the replacement. It's not as bad, but still sensitive to knocks unless the gain is cranked way down.

Jim

-

I had it on the first coil I got, and also, but not as bad, on the replacement they sent. Only the 10". Haven't seen it on either the 6", or the 14". Still really like my 24K. I can fix the first one. I know where the problem is, and can build a bridge over the location causing the problem. I haven't diagnosed the problem with the second one. I'm glad that Steve sent me back the bad one when they warranteed it. Good to have a backup, though not as important now that Garrett has picked it up.

Jim

-

2 hours ago, rexhavoc said:

Thank you GMS, you are a wealth of knowledge, as always.

Now, speaking of Vintage - if only we could resurrect the gpex.ca web site. That was a real loss to the prospecting community.

Yup...I really miss that forum. Great to see GMS posting, too!

Jim

-

2 hours ago, jasong said:

Could it be done in theory? Yes. Is it feasible for exploration? No.

I want to cover a lot of ground and process a lot of dirt exploring, if I find a place where there is a good concentration of gems eventually, I'd probably try hauling water.

I want to cover a lot of ground and process a lot of dirt exploring, if I find a place where there is a good concentration of gems eventually, I'd probably try hauling water.

I was using about 300 gallons per cubic yard when I hauled water into a pond in AZ for a gold operation before silting up. I've heard figures of 100 gallons per cubic yard recirculating, but that must be for clean gravel. That was a place I already knew where gold was and didn't have to set up/break down/move around, and I hauled 5000 gallons in at once. I'd never do that for exploration.

Yep, actually it was easier/closer to get water in to places I was working in Arizona than it is to the places I want to explore in Wyoming.

I agree, I think the classify method is the best bet/quickest/easiest now. I might just classify into labelled buckets and bags, and bring everything home with me.

Of course last night and today we are getting rain and cold weather now...haha oh well. Not enough to make washes run, but enough to dampen all the dirt.

Aah man...just a little dampness, and the classifying is about over. I love Wyoming, but you guys, like us, have a short season...LOL. I'm looking forward to heading over next spring. Keeps me alive having things to look forward to...Ha!

Jim

-

9 hours ago, jasong said:

Working lamproites or kimberlites? For diamonds, my intention was to explore all those lamproites since they appear underexplored (also hence the total lack of water out there). Working wet is not an option to me.

I hadn't, though Dan Hurd is one of the few prospecting channels I do occasionally watch. But he is on a river here. Working with water and gems is much easier. He's using a saruca basically, or in other words doing a sort of hand jigging similar to the process Off Grid posted, except with no machine. Also, in his case the sand is already filled with garnets in every handful. Some places I want to explore will be like 1/4 to 1/2 yard of dirt to maybe 1 gem, it's quite a bit harder to recover the latter vs the former, the lack of water makes it more so.

Processing the amount of dirt I need to process would just require a crazy amount of water hauling if I did that in a tub, and the remoteness makes hauling water infeasible in any quantity. Wyoming is similar to Nevada in terms of remoteness of some areas, except often the roads are rougher/rockier since there is less "basin", and a lot of "range" (or rocky hills), comparitively.

Few people realize how dry Wyoming is. It's mostly an enormous desert, with few non-seasonal watercourses. I can't imagine trying to haul 100 gallons on a 4-wheeler, for instance. That's nearly a half-ton of water. And even that much water doesn't go far with all the clay, etc. Best method I used last summer was to classify down to two sizes, and to get rid of everything smaller than #16, and then haul the remainder to a stream and run it through my portable Pleitz jig. But, I had to drive 15 miles to water, on gravel roads for every batch. Did recover garnets and chrome diopside, though.

Jim

-

Testing my initial dry jig, I recovered some garnets, and thought it worked for gems, but later determined it was because the garnets were smaller than the rest of the material. When i realized that, I corrected things, so people didn't think it would work for gems. That was a few years ago, and I've learned a lot since, too. The real basic problem is the fact gems are only about 50% heavier than the background material. We are asking a lot of a machine to separate them by gravity with that tiny difference. It's possible a machine could be built to do that, but it would require adapting the unit for each gem type, and each background material...a real PINTA, and losses would probably still be high.

For diamonds, a dry screen is dandy. It's best to pick them out dry anyway, as they sparkle even when dry, and everything shines when wet, so tends to mask the diamonds.

-

18 hours ago, jasong said:

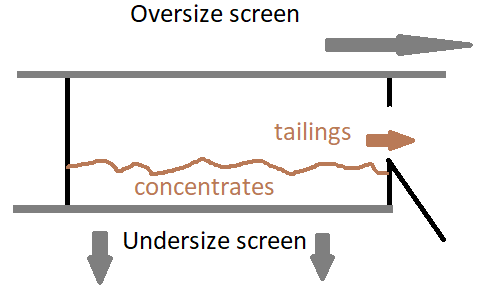

Here is a very crude drawing to illustrate the idea of using granular convection (aka 'brazil nut effect') as a benefit, instead of a hinderence. This is what I'm wondering if Jim experimented with.

The idea being this: let's say your gems are on average no smaller than 20 mesh. And on average no larger than 1/4". You'd set your bottom screen to be 25 mesh and your top screen to be 3/8"-1/2". The vibrator on the jig should automate the screening process too.

So, now the granular convection "problem" may actual help. Because the gems will among the smallest gravel sizes and thus will not convect up to the top with the larger pieces. The larger pieces should act to keep the smaller gems buried and in the jig. As long as the gems are always smaller in size than the average gravel pebble, granular convection should actually increase the efficiency rather than decrease the jig efficiency. At least in my head that seems like worth experimenting with. I think the key would be proper screen selection for any given environment/targets.

Further, there is also the standard jigging concentration effect going on top of that too. Seems like it should work? The undersize could be bucketed and run at home in a sluice if losses are a concern, the oversize should be able to just be eyeballed.

Trouble with this, Jasong, is all you'll build is a classifier. You'll just collect all the gravel sized between the oversize screen and the undersize screen. But, I don't want to discourage your thinking. Keep at it, the answer may be out there, though some very bright people in the packaging industry, have been trying to solve this for decades, with few results. Here's another thing to throw your way....the shape of the container has a large bearing on GC, and can actually make GC work in reverse, in some instances.

Jim

-

I've done a large amount of experimentation on dry gem recovery. Mostly because of my prospecting in Wyoming. I've made several mechanical units to accomplish that before deciding you can't defeat "granular convection". It may be possible to use it, however. I have not looked into that. I am currently working on a dry sluice for gold, however, that works really well. I recently went to Wyoming, and tried it on one of the WPA club claims, and found considerable amount of flour gold with it. Unfortunately, I have already said more than I should regarding that sluice. Since I'm going to apply for a patent, the less said at this point, the better.

Back on the gem recovery, dry. There is no way, using gravity, to recover gems dry. Can't be done....with one exception, which is moot anyway because no gems have high enough density to make it work. My experiments suggest that granular convection stops operating with a density ratio around 4:1. Since most soils are about 2.5, the gems would need to be at least 10, and I know of no gems that are that dense. The same applies to trying to separate heavy metals from black sand (another failure of mine....LOL). Operating dry is a whole 'nother world from working in water.

Interesting, though, and the rewards of finding solutions, would be great.

Jasong, I would consider it an honor to meet up with you someday...I think we'd hit it off.

Jim

-

4 hours ago, Geotech said:

Yes, lowering the cap values makes the demods faster with a slight loss of depth. I would leave them alone, I'm not even sure why Reg lowered them on the SL as it also tends to be noisier.

Ya know, Carl, I haven't seen much increase in noise on mine, after doing the mod. I did see a big difference in allowable swing speed, and yet still see very small targets. I think it was a good mod to do, for me. From the sensitivity I've seen on mine, compared to a lot of the videos I've watched, I think my SL is very good. Besides reg's mods, I've also added vernier controls on both GB, and Threshold...makes tuning really easy, and accurate.

Jim

-

I've read (maybe Reg told me) that the flyback resistor (R9) will run hot with increased voltage. That's the first place I'd look if my SL puked. So far, running hot batteries, I haven't had an issue over several years of use.

Jim

-

1 hour ago, Jim in Idaho said:

There hasn't been near as much posted on the threshold-smoothing mods for the Pulse Scan. I own an SL model, so didn't get involved on the mods for the TDI. I'll look around, but I'm not sure I have a copy of the TDI mods....only the SL.

Jim

Here's all I have on the smoothing mods. This was a post, a few years back, from Reg Sniff.

"

I don't do the mods myself. My hands don't work that well any more so I have a friend do them. He does the work and keeps all the money since the mod is somewhat labor intensive and does require a pcb trace mod.

A full TDI mod costs about $125 (return shipping included with $500 insurance) and that includes replacing the preamp with a much better IC, the addition of a small pc board to reduce the noise, a filter change so the regular TDI is upgraded to the filtering of the Pro for a faster response. The mod also includes calibration of certain stages to 1 millivolt to assure the mod works as designed. This TDI pro filter mod makes the regular TDI like the Pro but without the extra GB pot and volume control. The volume control was added to help reduce the noise problem, but with the noise reduction mod, is not needed for that purpose any more.

One additional mod is to short out a capacitor which eliminates a third filter that is not needed and can cause weak signal problems. This mod does increase the gain which in turn increases the noise level. Fortunately, reducing the gain using the gain control about 20% or so makes it back to normal. You do gain a little depth but more noise with this mod. One advantage of this mod is weak signals become more reliable.

-

3 hours ago, Melano87 said:

Hi Jim, thanks,

What are the mod, because despite my research I can't find an explanation?

David

There hasn't been near as much posted on the threshold-smoothing mods for the Pulse Scan. I own an SL model, so didn't get involved on the mods for the TDI. I'll look around, but I'm not sure I have a copy of the TDI mods....only the SL.

Jim

-

7 hours ago, Melano87 said:

Hi Carl, thanks again.

I still had a few questions:

- Do the Pulse Scan TDI/TDI Pro and TDI SL turntables have big differences (performance), if so which ones?

- Are the Reg changes applicable on the Pulse Scan and should they be made to improve? If so, what are the matches of the C20-C21 capacitors to be set to 0.22uF, the C56 capacitor to be removed, D20-D21 diodes, jump over the C42?

Regards.

David

Those mods apply to the TDI SL, not the TDI Pulse Scan. The mod for the original TDI's was to smooth the threshold.

Jim

-

8 hours ago, chiil said:

Interested in? As in your are selling your TDI SL?

8 hours ago, chiil said:Interested in? As in your are selling your TDI SL?

LOL...not a chance Chiil...sorry if I gave that impression.

Jim

-

Answer #1...yes # 2 I have no idea #3 yes

An unasked question...can the SPP's be modded for more sensitivity and sweep speed....yes! And, I'm no guru...far from it, though I'm probably dangerous, in that, a little knowledge is a dangerous thing....LOL

Jim

-

I should also mention that Reg had a 3rd mod that I have not done on mine, so can't comment on. I found out only after modding mine, and haven't gotten around to it, yet. I can't remember the details, but the info is out there somewhere.

Jim

-

Yes...the pulse scan TDI, and then the Pro. The pro had better Ground balancing for the Australian market, but sold also in the US. Then the SL version, which fit ina smaller box because they went to surface-mount components, but it also had a different ground-balancing system, which improved the performance. Not much later Reg Sniff (RIP) started testing mods to the SL that improved the performance. His mods, which included improved sensitivity, and faster allowed sweep speed, without sacrificing sensitivity really turned the SL into a great machine. The factory finally relented and adopted the improved sensitivity mod into the factory models, starting sometime in 2015. Then the tan version, which also had the improved sensitivity mod. No factory unit ever had the faster sweep speed mod, though that's the easier of the two mods to do.

Jim

-

I'd buy one of those in a heartbeat, if it available near me, Jeff. You beat me to Jim's only because I was out of Internet touch for a few days in Wyoming. I knew when I saw the post, I'd be too late....LOL Should have known it would be you...Ha!

-

Forgot to mention...I was using the MJ 8 x 12 coil.

-

If anybody's interested, mine's a 2013 model.

Jim

-

Just a quick report on my heavily modded TDI SL. It stilll works very well, with my 16v battery packs. My wife used it on a recent trip to South Pass, Wyoming, and found lots of old lead bullets, cartridges, etc. A couple of days later, I took it out nugget hunting, and while I found no gold, it did find a piece of what looked like chewing gum foil about 3/8" long and 1/16" in diameter. The foil was 3" down. Doubt it weighed 1/2 grain. My TDI isn't a Minelab or Garrett, but it's still very sensitive, and i can swing it all day. The sensitivity and sweep speed mods, along with my vernier controls really make a difference.

Jim

-

I wondered if anybody from this organization is on the forum? I'm a new member, and planning on attending the Aug. 13th meeting at Atlantic City.

Jim

.jpg.315e3bd3307813c91df4930dc3a75102.jpg)

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

10” 24K Coil Issue

in White's Metal Detectors

Posted

I'd love to see "exactly" where you put the foam. I had a hard time from the pics.

Jim