steveg

-

Posts

1,207 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Posts posted by steveg

-

-

3 hours ago, Carolina said:

It can be removed and re attached.

In which case, a small hole can be drilled in the mount, and the wire could be routed through the hole in the mount (and the connector/clip then reattached). That is the IDEAL solution, but one that I feared some would not want to do (remove the connector/clip).

-

3 hours ago, Doc Bach said:

Hello Steve.I may have overlooked it but are there any future plans for a camouflage version becoming available?Thanks in advance.

Doc,

At some point, I plan to offer the Deus shafts in colors. For now, I'm doing black only, and working to sell enough of them to recoup my initial investment in the project, as it was substantial. Thus, that has prevented me from the ability to invest in building up an inventory of tubes in different colors. Gradually, though, as I recoup the initial investment, I plan to eventually add colored shafts as an option.

If you are set on a camo one, I may be able to get you taken care of with a "custom" build, using tubes already in stock; send me an email if you like, at steve@stevesdetectorrods.com, and we can discuss...

Thanks!

Steve -

2 hours ago, Carolina said:

I see now you use the locking mechanism which will more than likely prevent part of my mod. It has been my finding, that people’s hand slide up the handle while detecting into the bottom of the RC. This causes the RC to come loose. I wish we could have talked before you started and maybe a new handle could have been formed. I wrapped vet wrap around my handle heavily around the top and then tapered down the handle. It has worked for me. If you remember we talked about me testing others shafts and I’m the one who talked to Alexandre about your shaft locks. I doubt you will have any trouble selling boat loads of your shafts. Looks like a nice set up.

Carolina,

The locking mechanism would prevent a hole in the top of the mount, yes, but one could be place a hole in the top/side of the mount, achieving the same effect. But, again, it would have to be the bare wire, and not the wire WITH the connector/clip installed on the end of it, to be able to be routed through the hole.

As for the handle, I wasn't wanting to change it TOO much, from what people are used to, though I did make it a bit "taller." Overall, one goal I had during design was to try have the shaft feel "familiar," in many respects, to Deus users, and just change the things that were "flawed" (from my perspective). That's a part of why I didn't change the handle shape too much. I did change the location of the remote/mount on the handle (it is much more "recessed" into the handle, or in other words, "forward" (in a "coilward" direction); this not only makes the buttons on the face of the remote MUCH more accessible, but it also should minimize the tendency for the remote to "rub" on someone's hand the way it does when mounted to the stock shaft. And then, to account for situations when the remote IS bumped, the locking mechanism was added to the remote to minimize chances of the it being "bumped loose." The handle itself, though, was not mentioned by many as being a "negative." And since how a handle "feels" is a very personal thing, given preferences, various hand sizes, etc., I felt like any change I would make to the shape/style of the handle would please some, and displease others. So, again, I thought leaving it as close in shape to the stock handle as possible, was the best bet.

I had forgotten that you were the one who mentioned my cam locks to Alexandre (thank you, by the way).

The shafts are selling well thus far, thank you. I'm concerned that when the "special introductory pricing" period is over, they may sell more slowly; these are very expensive shafts to produce, and thus require a price point higher than I'd otherwise want. Part of the reason for that is that compared to the Equinox straight shaft, for instance, this shaft requires the inclusion of two additional (expensive) parts that the Equinox shaft does not -- the carbon-fiber arm cuff, and the carbon-fiber S-handle These two parts alone raise the cost of production substantially, which makes it difficult for me to offer them at price that is as affordable as I would otherwise like...

Thanks for the kind words!

Steve -

2 hours ago, Carolina said:

Start by taping the co ax to the end of a 1/4” dowel leaving about 12” of straight co ax. Then wind the co ax tightly around dowel until about 12” from the end and tape in place. The co ax is stiff so it takes a little effort and you need to have the tape already cut and ready to apply. Then carefully heat the cable with a heat gun ( PVC or Wagner paint stripper or hair dryer on hottest setting ). Once good and hot from end to end, place in the fridge for 10 min. Repeat this process 2 more times.

The trick on the mount, is to remove the two screws holding the mount to the shaft and remove mount. Then disassemble the mount face from the body by depressing the tabs on the side. There is just enough space to drill the hole for the grommet and cable. Now you can run the cable out the shaft into the mount and out, make a loop and then you can push the co ax thru the hole in the mount. Next slide the grommet over the co ax and insert in hole. Then holding the grommet in place, pull the loop out of the co ax. Reassemble the mount and install on shaft. Takes some work but make a clean mod.

Carolina,

THANKS for the info on the coiled cable. VERY good info...interesting.

As for the mount, that's a great tutorial, for the XP stock mount. Mine is different, injection-molded as one piece, and so taking the mount apart like that is not an option. That's why the only way to do it, would be if the plastic connector/clip were removed. Then, the "bare wire" cold easily be routed through a small hole drilled in the mount...

Thanks for the info!

Steve -

On 1/8/2023 at 4:38 PM, Carolina said:

Carolina,

1. How did you coil that cable? THAT is really what is needed, to do a GOOD "inside the shaft" wire run...

2. You are right; a hole in the mount is the best option. HOWEVER, after much work/effort, I could not locate a hole on the RC mount that would allow the wire -- WITH that plastic connector -- to exit through the hole. The lack of flexibility of the connector, the size of it, etc., simply thwarted any attempt I made to find a place that I could include a hole on the mount (with respect to the way that the mount is designed, internally). HOWEVER -- it would be EASY to locate a hole on the mount, if all that was needed was to pass the thin wire ITSELF through (i.e. without connector). SO -- if anyone wishes to modify their antenna wire (remove the plastic connector/clip, at least temporarily), then routing the antenna wire through the mount itself becomes trivial/easy to do. And YES -- just as you noted, for the reasons you noted (shaft collapsibility), that is absolutely the preferred solution (but which, again, the connector/clip prevented me from achieving).

Steve -

On 1/8/2023 at 4:25 PM, CarsonChris said:

Are these shaft's available now? I don't see them on the website?

Chris,

Sorry for the delayed reply; all day detecting trip yesterday, so a bit behind and trying to catch up!

I haven't put them on the "Products" portion of the website yet, as I'm trying to get all of the customers who are on my wait list outfitted, first. I have so many orders to fill, that I'm trying not to overwhelm myself with ADDITIONAL customers yet, LOL! When they DO go on the website, they will be at a higher price than the special "introductory" price I'm selling them to wait-list customers for. So, if you think you may want one, I'll add you to the wait list.

As for availability, parts are in production right now, for me to begin building the second batch of shafts, but it appears that there may be a couple weeks' delay for me to receive these parts. So, it looks like it may be the first week in February before the parts are shipped, and then mid February before I am building/shipping shafts...

Meanwhile, if you are wanting some detailed info on the shaft itself, I DO have a couple of my most recent "blog" posts up on the website; you'll find those posts under the "What's New" tab (www.stevesdetectorrods.com/blog/index.php).

Thanks!

Steve -

Nice job, Gordiedan, and I it was interesting to see the trace, and then the target after you dug it.

Steve

-

12 hours ago, longbow62 said:

Hey strick I always thought Park2 was better in iron than Park1 although Park2 was not quite as deep. Which AT modes act the most like Park1 and Park2?

Interesting that you say that.

I ALWAYS use Park 1, but recently, at some sites where the iron falsing was driving me absolutely crazy, I've switched over to Park 2, and it seems to REALLY settle down the falses...I was quite surprised...Is this what you mean by "better in iron?"

Anyone else find Park 2 less "falsy?"

Steve -

Tom --

You can (if I am not mistaken; it's been so long since I've played with the tone settings) adjust your "iron volume." Mine is low, relative to conductive tones, but I THINK you can run that up as high as you want.

As for copper vs. zinc pennies, it's not that difficult at all to tell the two apart, tonally, in turf-type settings. I have no issue at all (I also run 50 tones). But, on a salt-water beach, where you would encounter any and all stages of corrosion, all bets are off, I'd think. In general, there's a roughly 4 VDI numerical difference between a zincoln, and a copper memorial, so in 50 tones, that's quite a separation of tones. Again though, the beach may change all of that for the worse...

And yes, hitting the horseshoe button every time you turn on the machine will change the machine from discriminating iron (and thus iron giving you a threshold null like on your Ex.2) to allowing you to hear all iron (iron tone). Look at your "speedometer" dial, as you press the horseshoe button, and you'll see that the negative VDI numbers go from "no black tick mark" above them (discriminated out), to having the black tick mark above them (NOT discriminated).

Steve -

10 minutes ago, midalake said:

The coin is a combination ferrous outer ring and non-ferrous center.

On the Equinox they bounce all over with the short ferrous ID range from -4 to-7. I dig a few by signal size once in a while. But as we all know the Equinox does not size targets well by sound.

These coins are all over on the D2. Right now, my hunting style on the D2 has my iron tone/vol at 1. They fall solid in the iron bin, so I do not even hear them.

My hope for the Manticores expanded iron range is it holds a better range number and paints them on a certain spot on the screen. If so. I can notch that location on the screen.Got it. Makes sense now.

Steve -

2 minutes ago, midalake said:

I am interested in the manticore's ability to separate out those non-ferrous coins in Mexico. I think this is where the ferrous limits will shine. I look forward [if possible] to identify the Mexican 5-peso coins which is about 50 cents local worth. Right now, I have to pass these up with the Equinox and D-2. I am guessing on a yearly basis I am leaving $150 worth of these in the beach.

midalake -- why do you "have to pass them" on the EQX or D2? Because of the way they ID, obviously, but I'm not sure of the details of how they ID, that forces you to "pass on" them. Do they ID as solidly ferrous or something?

Steve -

57 minutes ago, Chase Goldman said:

Totally agree, Steve. But ML will want to wring some more dollars out of us to get that feature because they're likely saving that for the MantiNox 2500 with it's precision wound coils to exacting nanometer tolerances and 75% more coil power than the Go Find 66 and which will be announced to great fanfare and breathless claims of multi generational leaps in capability by erstwhile NASA engineering consultants and unbiased YouTube influencers.

I'm hoping that marvel of engineering prowess is not announced before I get my replacement Nox 900 back from ML warranty support or I might have post-warranty user's remorse.

On a serious note, ML's Ferrous Limit implemention, though daunting in its setup for some, is not really the issue. It seems more signal processing magic tweaking is required to get a subset of small ferrous from landing on or near the centerline (i.e., outside of orjust inside of the max Upper Ferrous limit setting). In other words, higher accuracy/reliability in generating the numerically hidden FE ID component of the TID. So even if ML provided FeCo 4-digit ID, that would only be as reliable if you could actually bank on the accuracy of the provide Fe ID.

Chase,

I hear you, on your slightly cynical humor in the first half of your post. I get it.

I WILL say that I understand the "multi-generational leaps" thing that is being referred to, and I get why it's been said, but I also get why that statement might be misconstrued by some to think that this means that the machine is going to give you a an on-screen, photograph-quality picture of each target in the ground, AND dig it for you! LOL! But, in defense of the statement, I think there are some very significant engineering achievements built into the unit, in SPECIFIC aspects (EMI handling being one of them) that are indeed major engineering breakthroughs.

Let me illustrate with an analogy. Consider a vehicle. When we moved from carburetors to fuel-injection systems, that was a HUGE engineering leap, in terms of internal-combustion engine development/advancement. HUGE. An engineering marvel, some would say. It revolutionized 100- (or more) year-old technology. BUT -- to your average car owner, did they see it quite that way? Yesterday, I could drive my car with carburetor to the grocery store with no issue. Today, I can drive my NEW car with fuel injectors to the grocery store, with no issues. So what's the big deal? NOW -- would ANY of us, today, opt for a vehicle that utilizes a carburetor, instead of fuel injection? I don't think so; most would agree that fuel injection is a far superior way to achieve proper gas/air mixture, get it to the cylinder, and thus improve internal-combustion engine performance. So -- YES, I feel it was an engineering marvel. BUT -- I also can imagine why some, at the time of its introduction, would have said "What's the big deal? I've been misled by false claims!" What an engineer sees as a "huge leap" in technological achievement may not always translate into something that a CUSTOMER feels is a "huge leap," but instead just a small, incremental improvement. I know you are (were) an engineer, so I know I'm preaching to the choir a bit, but...

ANYWAY, how much these "breakthroughs" engineered into the MC translate into actual, improved performance for us, remain to be seen IMO. BUT, with that said, I am 100% convinced that EMI mitigation is a big part of this discussion, and that the "long-press" trick that NASA-Tom described, when doing a noise cancel, is a key to unlocking this particular "engineering marvel," so as to coax maximum performance from the unit. I could elaborate on this...and will if anyone wants to read a way-too-detailed and way-too-lengthy post, but I'm being cognizant of the tl;dr problem!

NOW -- switching gears; as far as ferrous limits, I totally agree with you. There are two issues at hand, that have to be considered separately. ONE, is knowing how to set your limits up properly to best take advantage of what the machine IS capable of, but the other of course is that there's no way ferrous limits can help in improving anything if the machine itself is NOT capable of providing accurate target identification. You and I totally agree on this.

My focus here has been hoping to help people without prior FBS familiarity, to better understand FE/CO, and the 2-D screen, and how setting proper "limits" is of huge importance. There are nuances and subtleties there that will TOTALLY affect what we hear, and thus what we choose to dig. BUT -- all of that is based on the ASSUMPTION that the machine is ACCURATELY ID-ing the target IN THE FIRST PLACE, which is YOUR point. And you are spot-on, of course, because if the MC is INCAPABLE of properly IDing a nail, for instance, then all of the understanding in the world of 2D display and 2-digit VDI and ferrous limits and everything else, becomes a moot point (for those improperly ID-ing targets).

So, yes, we totally agree. Again, there are two separate considerations here; ONE is knowing what limits are, why they are important, and how to set them up, so as the coax from the machine "the best that it is capable of." That video that was linked by cobill does a very good job on illustrating that, in my opinion. BUT, that still leaves the issue of what IS "the best that the machine is capable of" in terms of proper target ID? For those nails that are going to "false" as good signals, and fall right on the "zero line" (the "non-ferrous" line), nothing in that video is of any utility at all, for those specific targets.THAT problem will have to be handled in a different way (which may include some combination of frequent/proper ground balancing, lowering sensitivity, increasing recovery speed higher than might otherwise be desired, changing detecting mode to one that includes a mix of higher frequencies, etc.) And ULTIMATELY, it may have to be handled with a MUU/update, as some have speculated. But, I think the jury is still out there; I don't think there are enough machines, in enough peoples' hands, for enough time, to conclude anything in that regard just yet...

Steve

-

On 12/27/2022 at 12:12 PM, cobill said:

Scoop,

Yes they are blowing this out of proportion. This YT video was released 11 days ago. Doesn't look that hard to me after reading the manual!😂

cobill,

Excellent, informative video. Thanks for linking it. For you or I, with Minelab FBS background, this makes sense. BUT -- for those who don't have that background, and have been a bit confused about the 2D screen, and how "ferrous limits" work, I'd think this video makes things ALOT more clear/understandable.

NOW -- if I can just talk Minelab into including a TWO-DIGIT display option for target ID (i.e. including the Ferrous number, ALONG WITH the Conductive number), then things (in my opinion) would be even MORE clear, as it would show more directly the relationship between the 2-number ID (FE and CO) that is being calculated in the background, and the 2-D screen (which is simply an x,y coordinate system, with 2-number coordinate pairs -- i.e. target IDs -- plotted on the coordinate system as the machine takes snapshots of the target).

Steve -

11 hours ago, palzynski said:

The center of gravity of a S rod is located a little upper than on a straight rod , then closer to the users's arm axis . Then a S rod reduces the pendulum effect ( less weight under the handle ) during the detector motion.

Long story short a S rod is a little more stable in the hand and more cumfortable to use .

This is why a lot of detectors use S rods I think . On the other hand S rods are more complex to design-manufacture , because of the more complex shape of the S handle . Steveg will probably confirm ... 🙂

On the other hand a Deus with a very light coil like the 9" FMF ( 330g ) is so light that the difference between a S rod and a straight rod is imperceptible to my opinion .

Personally I use a straight shaft coming from a Quest Q30 , and will probably order Steveg's carbon shaft as it is lighter than mine ..

Good commentary, palzynski.

And yes, the S-shafts are much more complex (and expensive) to design, and manufacture. 🙂

BUT, SINCE the Deus is designed to use an S-shaft, and since I thus designed an S-shaft, it's also complex/difficult "go back the other way," so to speak, and alter the "S-handle" design to turn it into a straight shaft (like the one I made for Steelheader).

Steve -

Yep, air test can kind of do it, too...but I've come to prefer test garden testing. Once you learn your test garden, and how each coin responds to a given detector, it's very informative to then see how a different machine responds to those different coins.

As just one example...I have an 8" quarter in my garden that is harder to detect than the adjacent 10" quarter (probably a fleck of iron near the 8" quarter, or something like that...) I know this, and so when I am testing a new machine, it's always informative to hit those two coins in succession...and compare to responses (that I have in my mind) from other, prior machines...

Totally agree on the iron volume; I want it THERE, but quiet, and definitely prefer that over discriminating iron, and getting just a threshold null...

Steve -

8 hours ago, fishersari said:

Enhanced audio theme with rich profile

My concern is the deep faint signal "missing' when using the audio setting above.

Are you saying that when using "rich," that you fear that the modulation of the signal (quieter with depth) might lead you to miss some very deep (quiet) targets? I've been thinking about this myself, as it relates to the MC, as I LOVE modulated audio, and LOVE what I've heard on a couple of videos in terms of the modulation of the "rich" audio.

To elaboarate...I had debates about such audio modulation years back, with other Minelab Explorer users (when I was a relatively inexperienced Explorer user). When I first was getting used to settings on that machine, I arrived at what I preferred rather quickly, which was to set my "modulation" on the Explorer (I forget what it was called..."audio limits" or something) to a setting of "7," and for me, this was perfect (so I thought). BUT I was talking to/learning from a VERY experienced Explorer user -- much moreso than I was at the time, i.e. a "guru" -- who INSISTED that running that setting at 7 (on an Explorer the lower the number you placed that setting at, the greater the modulation) was a HUGE MISTAKE, if one didn't want to miss the deepest whisper targets...and as such, he always ran his "modulation" or "audio limits" or whatever it was called, maxed out at 10, at all times, for that reason (i.e. deep targets sound just as loud, or at least nearly as loud, as shallow targets).

Finally, I HAD to settle this for myself; debating it was just not going to settle it in my mind. SO, I decided to test; I set up a test garden, buried a bunch of coins and such at various depths, and then ran my Explorer over the deeper coins in my garden -- the ones that were barely detectable. I started by running the unit at my preferred "7" setting, and then switched it, and ran it at his "10" setting. I could hear the deep ones fine, either way. YES, his "10" setting made it much louder, but the negative was that of course it gave little IF ANY information as to whether it was a 3" target or a 9" target. At my setting of "7", it was MUCH quieter, but still very "audible," and the benefit for me is that I KNEW that the target was deep, due to the modulation. This is HUGE, to me...there are sites I ONLY want to dig deep targets, and having everything sound "loud" but "shallow" drives me nuts!

My conclusion, after all that debating, and then testing it for myself? We were probably BOTH right -- in that he probably had some hearing loss that affected his ability to hear the deepest targets, if he was set at "7." For me, however, with my younger ears, I had no problem hearing a fringe-depth target with the unit set at "7," so in the end, the "right" setting for him was not the best for me, and vice-versa...

SO -- long story short, I'd like to hear your thoughts here...as this is very important to me...

Steve -

13 hours ago, scoopjohnb said:

The 2 D screen takes a little getting use to, as I’m a CTX guy.

Can you elaborate a tad on this, speaking from one FBS guy to another? I do NOT have an MC yet, have NOT read the manual in detail yet (I find it easier to examine manuals in depth, only with the item in-hand). But, with that said, I've been pondering/imagining in my mind what I know about FBS and smart screens, and what I THINK I may know about the MC 2D screen, and would be curious to hear what "takes getting used to," as this implies there are differences that are a bit "confusing" at first?

Steve -

17 hours ago, strick said:

Table topics is when a bunch of professionals with advanced degrees get in a room and voice their opinions and experiences on certain topics...you can sit for hours discussing something that is totally apparent to some and outer space to others.

Someone threw jet fuel on this thred when I wasn't looking lol. I started using the CTX in 2014 and have countless hours on that machine. If one is familiar with the CTX then they will have a shorter learning curve on the Manticore. The Manticore is also related to the Nox 800 and those that have used the 800 will have a shorter learning curve as well. But I feel the machine is closer to a super sensitive CTX than it is to the Nox.

That being said it is not a perfect fine tuned machine in most environments as of yet. My feeling is that it could still use some work...I have been posting positive on it since I've had it because it's been working very well for me so far...EXCEPT for today. I hunted two spots..Urban areas with lots of EMI and old dirt with lots of iron and trash...Look at the quarter below with the eagle button and how much it's deteriorated in that soil. I really struggled with the machine today. Even did factory reset. The problem for me today was not deep iron targets but rather lots of falsing on shallow targets. I honestly don't know if there ever is place where you could max out the sensitivity on this machine. The highest I've ever been able to run it was on 26-27 and thats pushing it. It gets too chattery if you run it any higher where I live.

This machine is very sensitive to iron and ground conditions. So far I have not had many problems with deep iron it's the shallow falsing that is an annoyance. I have not been running the sensitivity lower than 24 which may be my problem. I manual ground balance frequently. Below is a picture of iron nail/spike with large head. It was close to 12 inches deep. The TT was pegged all the way to the right and read 99 on the VID and gave clear high tone signals 3/4 the way around the target but did give a audible iron grunt with red line...I knew it was iron but dug it anyways just to prove it to myself...

i'm out of time...I'll be back...tumbled some finds and a couple surprises.

strick

14 hours ago, strick said:One more thing I will add quickly. I have not found any difficulty judging the size of targets such as tin cans and low conductor pieces of can slaw in the mid teens etc...I think it’s a little deceiving looking at it on videos as compared to in person actually running it. Also the bottle caps are easy to identify... most wont even give a tone when hunting in disk mode just like the ctx....yeah there are a few stragglers that will read just outside that lower limit zone but if it’s not on the center line it’s most likely a junk target. It’s been great on bottle caps when hunting in parks. Even the steel caps covered with foil are not a problem once you have dug a few. We need more users right now..

strick

Excellent and informative posts, strick...

Steve -

18 hours ago, GB_Amateur said:

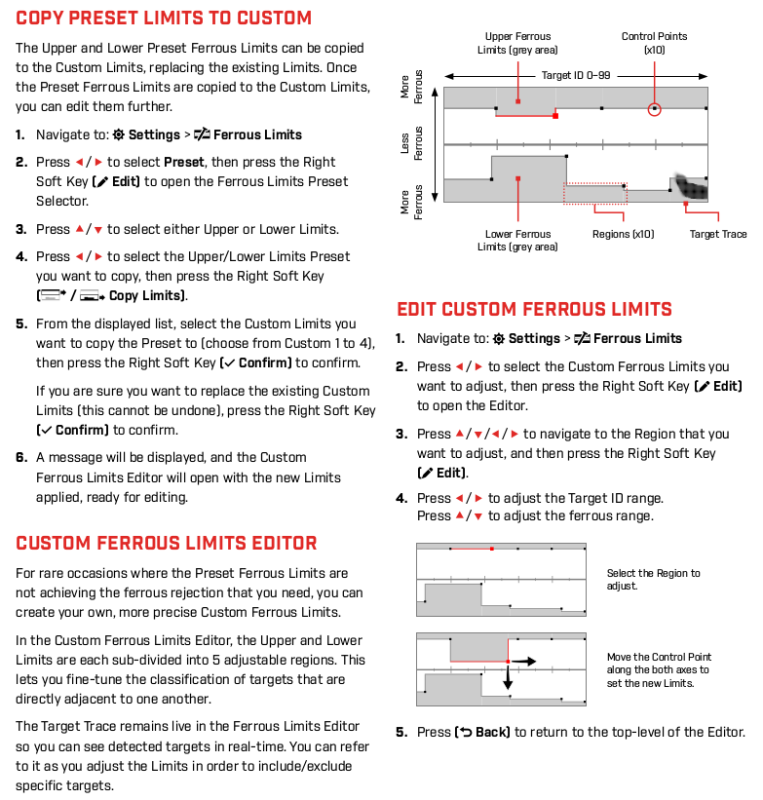

I've yet to see anyone customize the ferrous limits. The case you make may well be the best case solution, but I'm reproducing a page from the manual:

Note the graphics in the right column under point 4., as well as the instructions there. It appears both the starting points and widths (5 bins?) in each of the upper and lower ferrous limit sections as well as their amplitudes/magnitudes can be adjusted. How much will this help ID'ing falsing iron? I don't know. Does anyone yet know? (That question is rhetorical, BTW.)

Maybe I'll swing down to Oklahoma and get some lessons from Steveg after we both get our units. He may think he writes long posts but I can hold my own against the best here on that front. But I promise to zip my lips and listen, at least for the first 15 minutes or so. 😄

Meanwhile I hope Minelab is paying attention. They made some appropriate software updates for the Equinox 600 & 800. Let's see that R&D money they brag about continue to be put to good use here, please.

LOL! You are more than welcome to head down my way; I'd love to chat/learn/hunt together!

Steve -

19 hours ago, Chase Goldman said:

I don't have expertise on that. Perhaps setting up a live, interactive, scheduled zoom or teams session for DP members to participate in would be a good option. Anyone else who has any ideas along these lines, please feel free to chime in.

Chase, a zoom meeting or Google meet is a GREAT idea...

But, I also decided since posting yesterday that perhaps my arrogance may have gotten ahead of me, in thinking that I have anything of enough value to say, that would be helpful to anyone. I know that as a long-time FBS user, there are things in my head that I think would help, in terms of translation over to the MC...and an "interactive" discussion would be good in that regard. But on the other hand, I would hate to have folks say "I wasted my time joining that meeting thinking I'd learn something, and that bozo didn't tell me anything I don't already know!"

So, not sure what to do...

Steve -

On 12/18/2022 at 5:29 PM, Skate said:

Very nicely done. My lower shaft camlock is starting to loosen up on my D2 so I'm likely going to need a replacement soon. Once the holidays are over I'm going to stress to my wife that without a new set up I will become just average and all her new rings will be junk unless I get this.

Skate, I never replied directly to this message, but it made me chuckle! 🙂 Yes, you can tell her that you certainly won't be able to find rings anymore unless you have a new shaft (and the prior ones you've found her will turn into junkers unless you upgrade, LOL!)

Steve -

1 hour ago, Chase Goldman said:

It's not clear that Brass Medic is just using the canned settings. I think he was experimenting with some of the other All Terrain modes and indeed using defaults, but Brass Medic is an experienced CTX user (he states that he bought one when they were first released) so he knows how to set up the 2D disc patterns, yet he IS saying that M-core needs an update to address nail falsing. I am taking this to mean that even with enhanced upper ferrous limit adjustments from the defaults for his preferred All Terrain mode, he is still having issues. Can't be 100% sure of this, but it seems to be the case.

This is not just about the 2-d screen info nor denigrating the visual capability of the feature. If upper ferrous limits are working as intended by the design and are appropriately adjusted, then, as described in the manual, nails should also sound off (not just display) as ferrous even if their TIDs reside in the non-ferrous region. It appears that nails are really showing up near the centerline, this means you have to set really aggressive upper ferrous limit settings giving you a very narrow margin of error such that you can start to get false ferrous indications for non-ferrous targets that are showing up slightly off above the center line. This situation would be a highly undesirable versus simple ferrous falsing which is more of an annoyance/time waster, at least in those cases you actually recovered the target versus unknowingly rejecting non-ferrous and moving on without recovery.

I agree we can't conclude that features don't add value yet today because we need to give ML a chance to fix the issues with an update. Otherwise, it is not looking good in its present state based on a number of things that occurred in this and other videos namely: the iron nail falsing, bottle cap "false", and the beer can that looked like (on the 2-D display) and ALSO sounded like, a coin. Hopefully, ML can address these issues with additional time and effort.

There is SO MUCH I could say here. I really want to do an interactive YouTube livestream...

Your middle paragraph above is PARTIALLY true, but not entirely...

I need to ponder how to collect my thoughts and communicate them.

Is doing a YouTube livestream (if you have a channel already) a hard thing to set up/accomplish?

Steve -

2 minutes ago, Chase Goldman said:

That doesn't stop me, Steve.

It often doesn't stop me, either, Chase...but I know I annoy people and don't like to do that. I just had someone on one of the forums yesterday, after I posted a reply to what he posted, say "we said the same thing, I just didn't take 300 words to do it like you did..." Ouch! 🙂

Steve -

Maybe someone could tell me how to do a YouTube livestream...and then anyone who wanted could tune in...LOL...

Steve

.thumb.jpeg.84115f5937c08fe21a1976aafedc76fc.jpeg)

.thumb.jpeg.2cb6236441d19c3de31a3c7e7878c22b.jpeg)

Deus Shafts In Production...

in XP Deus II Forum

Posted

Sure...

PM forthcoming...