-

Posts

795 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Posts posted by afreakofnature

-

-

I’m a Saturday Sojourner. 6-8 hours each week until Snow hits.

-

2

2

-

-

7 hours ago, Daniel Tn said:

Didn't Tom also say that they had worked on the Beast's ability to handle EMI more since he had it on an inland site where he was running it at 28? I may be remembering wrong but I thought he said his most recent testing and input had been salt beach hunting and tackling that. Which hints at further development of EMI handling to me. I know they have said the machine in the videos is not the final product, that they are buttoning up some loose ends. I hope so because what I see and hear in the videos, is a very sparky/chatty machine. I'm not a fan of running them that hot when they chatter at everything, just holding it still.

Ala GPX6000 in VLF tech.

-

5 hours ago, vive equinox said:

That is the question 🤔

So why ate you not emailing Minelab like GBAmature suggested instead of asking forum members who have no clue?

-

2

2

-

-

Need a first GPX 6000 update…..first 🤣

-

4

4

-

-

Definitely need a 6” or 5” for that Goldfields mode.

-

2

2

-

-

The lead engineer in one of the vids said 50% more power than the Nox. It doesn’t mean the Core will have 50% more depth (although would be nice for detecting junky nugget ground). With more power though comes more EMI a la GPX6000. Can’t waith to hear people starting complaining about this noisy detector when you go above 21 on sensitivity. 🤣🤣

-

15 hours ago, jasong said:

It must be low manufacturing tolerances because my 6000 shaft doesn't twist. I tried twisting it by hand last trip out just to make sure I wasn't crazy, and it was quite hard to turn. Yet my 7000 shift twists every 5 minutes, and that's the replacement shift they sent to fix my first twisting shift.

Yet another of those problems that seem common for some but not others on the 6000. Seems to indicate a problem with manufacturing consistency.

It makes me hope that new detectors aren't made at the same factory, or this might become situation normal in the future.

Yeah mine does not twist either. You have to tighten it down real good. Need strong hands 😂

But I would still switch over to clamps if Minelab will supply the clamps used on the “Core”

-

1

1

-

-

I hope we can get those cam lock parts for our GPX 6000 😂

-

2

2

-

-

Did my plug fix work?

-

Phrunt thanks for letting us know that the 10x5 and 11 are basically the same in sensitivity (and depth?). Could you also compare your 14x9? This is extremely helpful to me. Thanks!

-

5 hours ago, jasong said:

Not a stupid question, you are right about the connector. My 11" took a few iterations to get tightened up when I first got the machine (and a reverse multi-step process to get it to come back off recently), and I had to do that multi step push/screw process to get the new Coiltek on too.

I went to double check after reading this, and I was able to jam the connector on about 1/2-1mm further and get about 1/6th of a turn out of the screw afterwards. Took some real force. Not sure if that was enough to affect things though, I'll see next time I get out to the field.

Mine has zero wobble and i can no longer turn it. Fingers crossed maybe that was it!

-

3

3

-

-

Jason, i’m going to ask a stupid question but is your coil plug plugged ALL the way in? This detector has another flaw in it as well when you plug the coil in. You have to basically plug it in three times. You will plug it in, screw it on, push it in a little bit more, screw it on push it in a little bit more, screw it on. Keep doing that until you can’t repeat that any more, at that point you will have it fully in. Might be worth a try or to double check anyways. Other people had this problem until I pointed that out.

-

7

7

-

-

-

I agree with jasong, airtests are useful and done in a controlled environment. It allows you to see the raw power of each coil. Too many variables doing a test outside of a controlled environment. Once you can see the raw power of each coil and where its hotspots are you’ll have a better understanding on how to use it with the ground involved. I really don’t understand why people don’t like to see air tests it’s probably the most scientific way. When you only have limited time and for my matters weekends only, I like to know the raw power of each coil so I can help determine what to buy and what might work. I don’t have time or money to buy every coil and test it out.

-

3

3

-

-

I always planned on keeping my 6. No Axiom for me.

-

2

2

-

-

Condor going back to AU! I look forward to hearing your adventures. I still wanna get there and beginning to draw interest from others in maybe 2 years

-

Hell yeah wow indeed!

-

1

1

-

-

7 hours ago, Jonathan Porter said:

Probably the biggest issue I can see is the loss of the Rose joint, Minelab put a lot of work into that lower shaft connection to take some of the shock out of small rock touches ect, carbon fibre migrates every little touch and clip right through to the handle this shock/movement can also get into the coil cable and the coil connector potentially creating unwanted noise.

The Rose joint soak’s up a lot of side ways torsional twisting when the front of the coil comes into contact with something immovable, rather than put a big twist into the shaft (which acts like a torsion bar) it soaks up some of that energy like a shock absorber. The user experience is akin to running a dead dry chain on a push bike when you were a kid then oiling it, the difference was profound, assuming you were ever a BMX bandit as a 10 year old. 😊

Just my 2cents

JP

What is the “rose” joint? This is new terminology to me. Thanks!

-

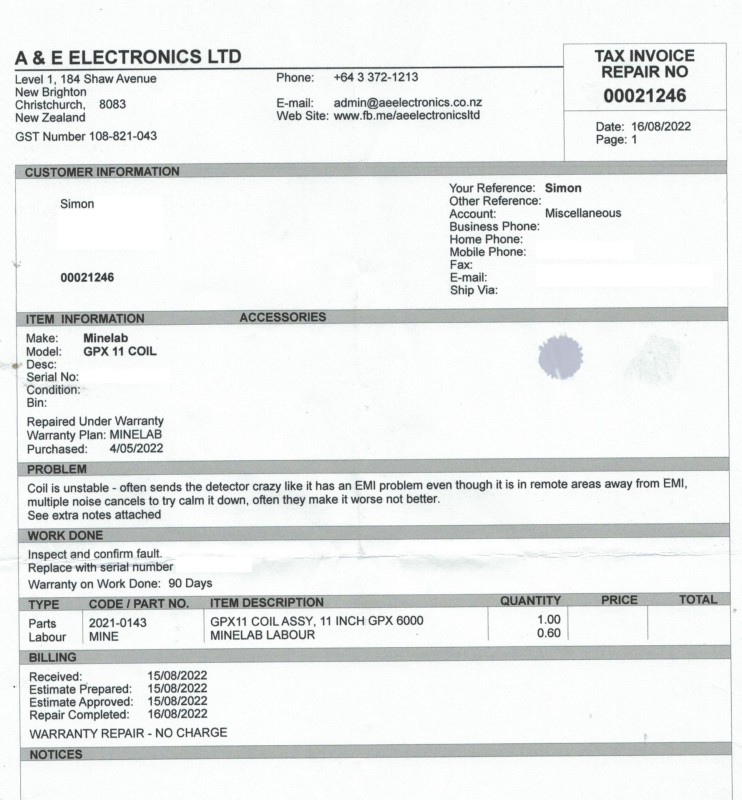

21 minutes ago, phrunt said:

To follow on from the earlier part of this thread as to if my GPX 6000 11" coil was faulty, it was replaced by our Minelab service agent, they were able to fault it which I'm very happy about, it means I hadn't gone crazy.

Now I will be able to compare it to the Coiltek coils properly, knowing it's a more fair comparison without the 11" being faulty.

Looking forward to the comparisons! 😊

-

2

2

-

-

Well we all complain about one thing or another that could be improved, just thought this time we could actually do something instead of just complaining to each other. Mine could use some tweaks but otherwise works great ATM

-

3

3

-

-

Anybody get any responses from Minelab? I have not

-

I see a lot of posting so I assume a lot of emails were sent 😁. Post the responses too if you get one.

-

Now that the Axiom is out and they plan on doing updates after user feedback within the first year, we should all send Minelab an email asking for an update to all our problems with the 6000 (and wants like Fe discrimination). Its been a year and complete silence. We have a big community here, maybe if we do that and include things like Steve offloading his (and he was a big part in the 6000), perhaps it will get their ass moving to do something. If not we might be able to assume its a hardware failure and move on to the Axiom and tell them that reason in doing so!

If you can type a post you can send an email. Shouldn’t take longer than 15mins. What do we have to lose! 😁😁

-

6

6

-

-

If everyone is waiting to buy an Axiom to see how they perform it would behoove the early adopters to stay silent and suck up all the gold before the rest of the band wagon joins. Just sayin 🤣🤣

-

1

1

-

New Minelab Manticore

in Minelab Manticore Forum

Posted

Air tests are great benchmarks for raw power. Everyone puts them down but you have to have a controlled no variable test to set a benchmark. Then compare to different ground types around the world.