White's MXT Engineering Guide

David E. Johnson, engineering consultant

This Engineering Guide is written to provide dealers and customers greater insight into what kind of product the MXT is, from an engineering perspective. It does not attempt to provide complete information on the features and use of the MXT: for that, please consult the MXT user's manual.

A BIT OF HISTORY

In January 1998, White's decided to develop a true multipurpose metal detector, with the kind of sensitivity it takes to be a real gold prospecting machine, and with computerized ground tracking for ease of use. White's in-house engineering staff was tied up on the project which eventually became the DFX. Therefore, in February White's asked me if I might be interested in taking on a new protect. I had a good track record on gold machines so it seemed like a good fit. I agreed.

A month later at a dealer seminar in Sacramento, California, Jimmy Sierra announced the project, and said if the engineer didn't deliver, the engineer would have to go into hiding in Mexico. I was sitting in the back.

We ran into one problem after another along the way. Jimmy, good chap that he is, didn't sic the thugs on me, though there were periods he was frustrated enough that the thought must have run through his mind. Although the project took longer than we expected we got two products out of it - the GMT and the MXT.

The first major hurdle was to get the basic circuit and software system running, with a first class ground tracking system. The system architecture was totally new, not a revision of the existing Goldmasters. In early spring of 1999 an ugly prototype was up and swinging, and Larry Sallee became involved in field-testing. By April the ground tracking system was working so well that since that time very few changes have been needed. At that point we knew we had a solid foundation, so work began on the display, discrimination and target ID features.

During the fall of 1999, we decided to tackle the problem of desert heat head-on. A lot of gold prospecting is done in desert heat in full sun. I set up a crude but effective, thermal engineering laboratory, measuring the temperatures reached inside housings of various configurations and colors in full sun. Then began the task of finding an LCD, which would handle the heat. Because the LCD display is an important feature of the MXT, we revisited the whole issue of display. The manufacturers of LCD display had expanded their product offerings. We found a larger one, and changed the mechanical design of the MXT to accommodate it. A FSTN 0160 F was selected, (there are more to choose from nowadays, so we used a bigger one than the GMT in the MXT.)

In early 2000, White's decided to bring out a new Goldmaster based on the work that had already been done, while development of the multipurpose unit continued. So we modified a prototype to work with the Goldmaster search coil at about 50 kHz, and you know the rest of that story - the GMT "tracking Goldmaster" was introduced in early spring of 2001.

As work continued on what eventually came to be called the "MXT", we spent a lot of time on the discrimination and target ID system. There are many different ways to do discrimination and ID, each with its own advantages and disadvantages, which aren't always known until you've had the thing in the field being tested for a while. A lot of work got thrown out as we found deficiencies in what had already been done, and discovered ways to improve things. As the project got closer to production, more people became involved with it, and offered their own ideas to improve it. The reason the MXT is as good as it is, is because of that long process of field-testing and revisions.

While the MXT was still under development, the DFX was introduced. The MXT design was then revised to run at about 14 kHz in order to take advantage of the DFX loops.

When it was finally time to call it "good" in June 2002, the MXT went into production quickly and smoothly.

CIRCUIT DESIGN

The circuitry of the MXT is almost identical to the GMT, which has already been on the market for a year and a half and has proven to be rock-solid.

The GMT's circuitry broke a lot of new ground. It uses a reactive impedance transformation network to boost transmitter voltage for higher sensitivity. It uses an active transmitter regulator to keep transmitter voltage constant even when the search coil is moved over black sand that would blow an unregulated machine off the air. The differentiator-filter circuits usually found in metal detectors are eliminated. Those functions are now done in software, which is made possible by the use of a high-precision 16-bit A/D converter used in a way that makes it equivalent to 17 1/2 bits. All the controls are digitized, their function actually performed via software rather than in circuitry. The audio system is temperature compensated in software to eliminate threshold drift.

For the MXT, we chose an operating frequency of 13.889 kHz. This is high enough to give good sensitivity to gold, low enough to give good target ID on typical coin, trash, and relic targets, electrically compatible with search coils derived from the DFX and halfway in between power line harmonics to minimize electrical interference.

SOFTWARE

The MXT uses a Microchip PIC 16C76 micro controller, chosen for its low power consumption and its set of features, which was a good match for this application. The software that runs in this chip is based on that in the GMT, but almost all of it is new or has major revisions, except the device drivers and the ground tracking system. Much of the new software is for target ID and discrimination, features that were not present in the GMT. Even the iron probability and VSAT systems in the MXT are new, despite their apparent similarity to the GMT.

The MXT/GMT does as much of the signal processing as possible in software rather than in circuitry, using what we call "low-speed DSP architecture". The demodulated signals are digitized, and processed and analyzed in software. Control positions are also digitized and made part of the data in software. The desired audio signal is computed, and then converted back to voltage using a 12-bit D/A converter. The circuit board communicates with the LCD and trigger switch in the "pod" via a custom-designed serial link.

In the MXT the filters, differentiators, and sample-and-hold functions are performed in software, not in circuitry. This eliminates the problems of channel mismatch and drift, which are often encountered in such circuits.

The discrimination system is a second derivative ("two-filter'') design for quick response over a broad range of sweep speeds. The analysis system for determining what kind of target is present has special features which reduce interference from ground minerals, and which automatically scale target ID confidence according to the mineralization level.

GROUND TRACKING SYSTEM

The ground tracking system comprises two subsystems: a ground analysis engine, and a ground balancing system. The ground analysis engine continuously monitors incoming signals to determine whether the signals probably represent ground, or may be something else such as metal targets or electrical interference.

Signals, which seem to be ground only, are put into a data analysis subsystem, which analyzes the data for a number of variables. Then it can be determined what the balance point of the ground matrix is and how fast that balance point is changing. It'd be nice to describe all this in detail but we'd rather not teach our competitors how to do it.

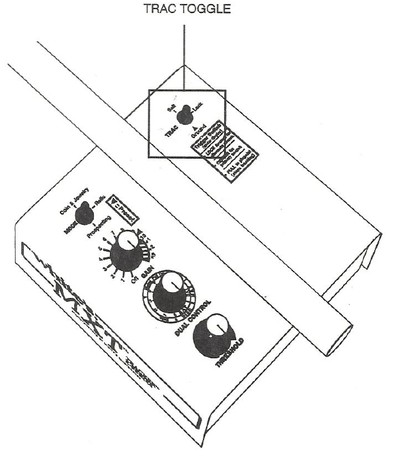

The ground balance system does the actual balancing of the signals, doing in software somewhat the same job as a ground balance knob does on a manually balanced machine. When the TRAC toggle is in the "ground" or "salt" positions, the ground balancing system follows the output of the ground analysis engine. When the toggle is in the center "lock" position, the ground balance subsystem stops following the output of the ground analysis engine, which is still chugging away in the background continuing to gather ground data.

The ground analysis engine can do a good job of telling the difference between ground matrix and anomalies such as hot rocks and metal targets. In order to tell the difference, it has to see matrix by itself during at least part of the sweep. When you're not in "lock", keep your sweeps broad, and don't loiter over the top of a target when checking it out. Otherwise the analysis engine may lose the ground matrix and start tracking into the target. However, if the target is strong enough to register on the VDI readout, the target ID system will tell the analysis engine to halt, allowing you to check the target without tracking into it. In all three programs, pulling the trigger to pinpoint a target also tells the ground analysis engine to halt. Some users will hunt with the tracking toggle in "lock", occasionally updating the ground balance by flipping into "ground" or "salt" momentarily when they start hearing too much ground noise.

The resolution of the ground balancing system is 1 part in 4,000, and most of that resolution is concentrated in the range where high mineralization occurs. Therefore, the individual resolution steps are below audibility under all conditions.

THE VSAT SYSTEM

The VSAT system on the MXT is similar in a general way to the one on the GMT. The VSAT function is done entirely in software. Up to about 2/3 rotation, the SAT is of the conventional (first derivative or auto tune) kind, giving a "zip" sound on a nugget and a "boing" sound on a negative hot rock (cold rock).

As you approach maximum rotation, the MXT goes into "HyperSAT". HyperSAT is a completely different type of SAT system with different sounds and target responses. The background threshold sound is a little rattier, but nuggets are crisper, the ground is quieter, and negative hot rocks vanish when you slow down your sweep. For all but the most experienced users whose ears are calibrated to hear every little nuance of a regular SAT signal, HyperSAT gives more effective depth in bad ground than normal SAT.

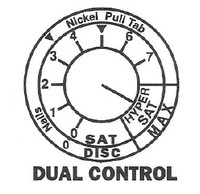

THE DISCRIMINATION CONTROL

The discrimination control does pretty much what you'd expect. Unlike some discriminators, when the control is at zero, there is no discrimination at all - i.e., "true zero discrimination" - and all targets will be detected. Below about 2, the discrimination is based on a combination of both signal phase, and signal strength relative to the strength of ground mineralization. This feature allows the user to get good rejection of shallow iron with minimal loss of deeper targets.

THE GAIN CONTROL

The gain control knob controls two things at once: the preamp circuit gain, and the software gain. The following is a simplified explanation which is not technically correct in all its details, but will serve to give a general picture how the gain control works.

As you advance the gain control from 1 to 10, the preamp circuit gain steps through five levels of gain: xl, x2, x4, x8, and x16. On most machines (depending on minor variations in search coil alignment) you can hear a momentary blip as the machine switches from one gain level to the next. The recommended preset (marked by the triangle) corresponds to a preamp gain of x8.

In mild ground conditions where there is no electrical interference, you may want to advance the gain control into the crosshatched region. In this region, the signal data in software is multiplied by successively larger numbers, increasing the loudness of the signals. It is somewhat similar to the "audio boost" function found on some other models of metal detectors. It's particularly useful if you're using the speaker rather than headphones and there's a lot of noise from traffic or wind, or if you're demoing the machine to someone else.

BASIC SENSITIVITY PERFORMANCE

Since this is a multiple-purpose machine, a U.S. Nickel coin is the most appropriate standard test target. With the gain cranked up, and in the absence of electrical interference, a nickel will typically "air test" beyond a foot using the standard 95O search coil. Your actual "air test" distance will depend on your hearing, the sweep speed, what search coil is used, how much electrical interference is present, and how you have the controls set.

In comparison to other machines in this price range, the MXT is extremely hot on low-conductivity items. On gold, it's right in there with the more popular gold machines, being especially hot on the larger, deeper nuggets. It will compete with all comers on low-conductivity , relics and on nickels. On high conductivity coins such as quarters and silver dollars, it is still an excellent performing machine, but there are several other products in the same league for sensitivity.

GROUND TRACKING PERFORMANCE

The ground tracking system is nearly identical to that in the GMT, which is widely regarded as one of the best tracking systems on the market. Compared to most other trackers, the MXT has superior resolution, tracks faster, "jumps" into new ground more quickly, has greater resistance to tracking into targets, and tracks over a wider range of soil conditions. The MXT allows tracking to be inhibited if desired.

DISCRIMINATION PERFORMANCE

All discriminator designs are compromises. Here's how the discriminator in the MXT stacks up against other machines.

AIR TEST "DEPTH": generally well beyond 10 inches, because of high sensitivity, with effective discrimination to within 0-3 inches of the basic air sensitivity of the target. Most discriminators will discriminate in air to within 0-3 inches of the target air depth on most targets, but most don't have the sensitivity of the MXT.

QUICKNESS & TARGET SEPARATION: among the best, because of medium-speed second derivative ("two-filters") design. Initial field reports indicate that the MXT's mixed-mode tone system gives indication of adjacent ferrous/nonferrous targets, superior to that obtainable through discrimination.

IRON REJECTION: Because of its high sensitivity and a slight preference in the software for not losing questionable targets, it'll be a little chattier than some less sensitive machines. Reducing sensitivity by cutting back on gain, or by reducing the threshold control setting to minimum, will help quiet it down when necessary.

DEPTH IN MINERALIZED GROUND: Although the MXT is a two-filter system, it incorporates special techniques which reduce ground interference and which reduce the "chopping & popping" which plague most other two-filter machines. This, together with its high basic sensitivity, makes it an excellent machine from the standpoint of discrimination depth.

FAST SWEEPING: Many discriminators tend to lose good target signals, even shallow ones, when quickly sweeping the search coil. The MXT is tolerant of moderate search coil sweeps, that is to say good at both faster and slower search coil paces.

SUMMARIZING: The MXT has the responsiveness and sensitivity of a first-rate 2 filter machine, combined with the discrimination accuracy of a first-rate 4-filter machine.

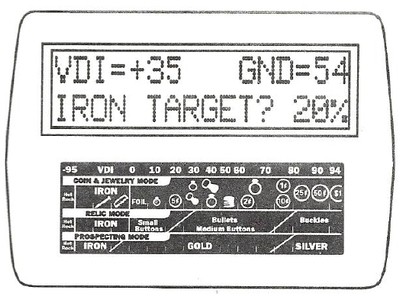

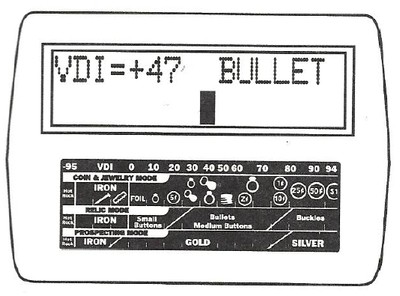

TARGET I.D., ETC.

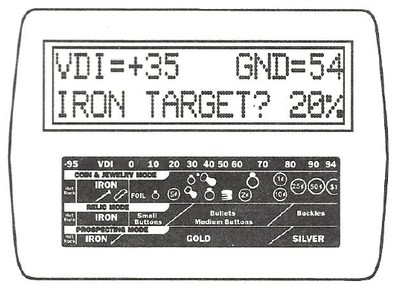

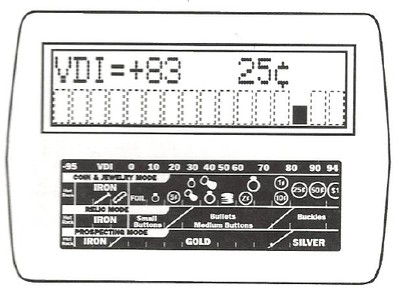

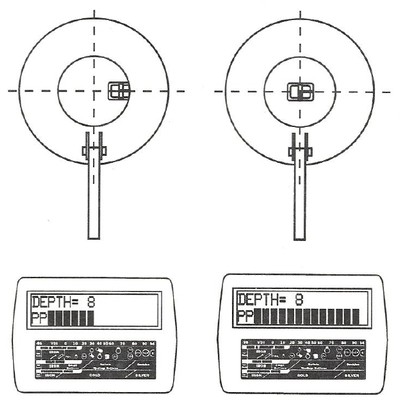

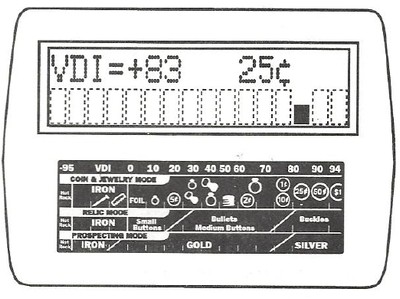

With its small medium and large blocks on the target ID screen, the ID system in the MXT bears a superficial resemblance to the "Signagraph" of the Spectrum XLT.

It should be realized that the traditional White's Signagraph system is typically (optionally) set to accumulate data over multiple passes over a target, and displays the accumulated average. The MXT displays fresh data on each pass and scales the size of the block according to how strong the signal was relative to the ground conditions on that specific pass over the target.

The visual ID system on the MXT is fast, easy to read, generally more accurate than the discriminator, and gives a visual indication (via block size) of how reliable the identification is. It is going to change the minds of many beeper enthusiasts who previously thought visual ID to be of little practical use outside typical coin shooting.

CASCADE

THE CASCADE OF EFFECTS OF GROUND BALANCE SETTING: In order to know what the ground balance setting is; flip momentarily to the gold program if you were in another mode.

Electronic ferrite material and most "negative hot rocks" (cold rocks) will usually read in the 75-88 range. Most soils will read somewhat lower. Readings will almost never go below 25 except in salt or moist alkali soils. When readings indicate smaller numbers than 50 you may notice some reduction in sensitivity. Below 35, some rusty iron may give unpredictable responses. Below 25, iron objects may give unpredictable responses and/or may disappear entirely and the sound on nonferrous objects may become slightly more abrupt.

MANY THANKS

To Kenneth White and Alan Holcombe for having sufficient confidence in me to put food on my table through the good times and the rough times on this project. To Jimmy Sierra for having the patience to argue with me about all the stuff that needed arguing about, for being so passionate about the need for this product, and for being willing to compromise when that's what it took to keep the project moving. To Larry and Sue Sallee, for their personal hospitality and for field testing prototypes. To Keith Zorger, Randy Smith, Mike Brighty who field-tested and helped develop the MXT. To Bob Canaday, for being such a competent technical/engineering liaison, doing a lot of not glorious but necessary work well and managing the project during its sometimes difficult phases. To Rick Maulding, for overseeing the project, for technical contributions to the discriminator and to the salt system, and for committing White's engineering department's finest minds to engineering review during the "slow SAT isn't hot enough" crisis, which led to a major system revision that made the whole machine better. To John Earle and Dan Geyer, for diligently hacking away at problems until they became non-problems. To Steve Howard and Pam Godell of White's. There were other people involved in this project whose contact was primarily or exclusively with White's and not with me. The risk of printing credits is that one may inadvertently omit a name that belongs there; so, if I missed someone whose name belongs on this list, I'm sorry, it was an unintentional oversight. - D.E.J.

P/N 621-0468 published 8/2002 by White's Electronics

-

10

10

-

2

2