Search the Community

Showing results for tags 'recovery devices'.

-

I'm not much of a sluicer. I'd rater be looking for nuggets with my detector. I like gold I can pick up with my fingers lol. My wife bought a small Keene sluice box several years ago and we set up a recirculating system at home where we could run some dirt at our leisure just for fun. I never really liked my home made set up. Although it worked it was slow..It was like a mini high banker made with stuff I got at the local hardware store. I was wanting something more efficient. In my search I found Gold Fox USA. There is also an Australian version that is the same company with a dealer who distributes for them in Oz. I wont go into a lot of boring detail...you can go to their web site and face book page or youtube for that...However I would like to say that so far I am very happy with this little set up. I can run unclassified material through this sluice extremely fast. The trommel is five inches in diameter. I've only used it three times so far and time will tell on how durable it is but it seems to be very well built. The company has many different sizes and options available. They are fast and get the product to you when they say they will. If you have a question Kelly the owner will get on the phone and answer it for you. The Lil Monster Deluxe comes with a 12v 2000 GPH pump. You supply your own power. I am using a RV deep cycle battery that I had laying around. I also bought a 700 GPH 12v pump and am using the two pumps together. The reason being is the material I am running is mostly clay and I wanted more water to help break it down. The only thing you have to watch is that the jets that supply the trommel will get plugged with organic material. They are easy to clean. In fact if you turn off the water supply to the hopper so it feeds the jets only...the water pressure is enough to flush them clean most of the time. Give them a look. https://www.goldfoxusa.com https://www.facebook.com/goldfoxusa/ strick

-

How can I make a dredge for fossils. I don't want the fossils to go through the pump. I haven't bought anything yet...just using bucket classifiers and its painfully slow with all the blue & purple clay and leaves. We are on a small creek that runs through a swamp in South Carolina. Right now we are just going through piles of excavator dirt from the creek bottom but would like to get into the hand size teeth in the creek bottom. We are considering just using an excavator and a gas powered preasure washer to wash the fossils off the clay. Any help would save me time and money. Thanks?

-

I was cleaning out the shop and came across some extra PVC fittings and a 1/2” thick sheet 16”x9” of a black Corian like material I picked up as scrap from tap plastics a while ago. They claimed it was something special they had for some project and the material was very resistant to things sticking to it? Figured I’d see if it was good for use as a miller table, so I collected the odds and ends I could find cleaning my junk and Home Depot was kind enough to fill in the gaps.tomorrow if I get a chance I’ll run a little dirt through it. DIY Miller Table;

-

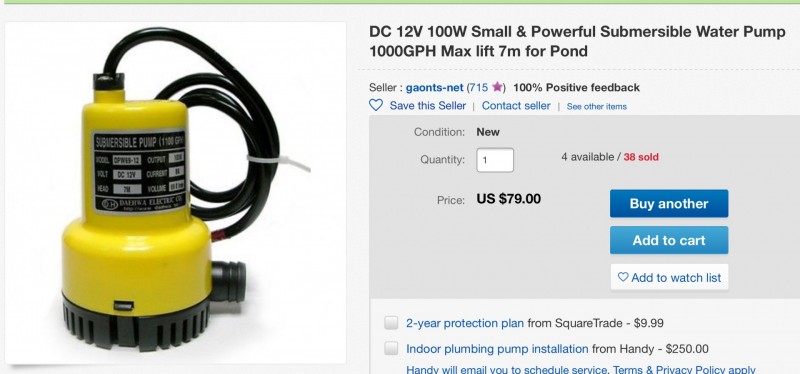

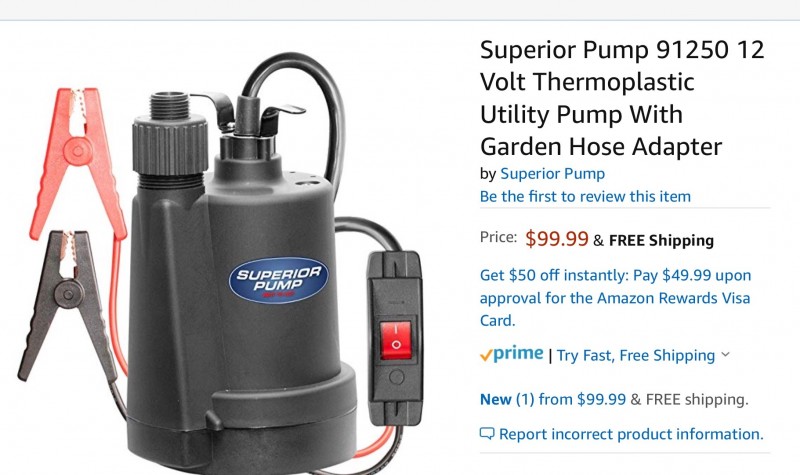

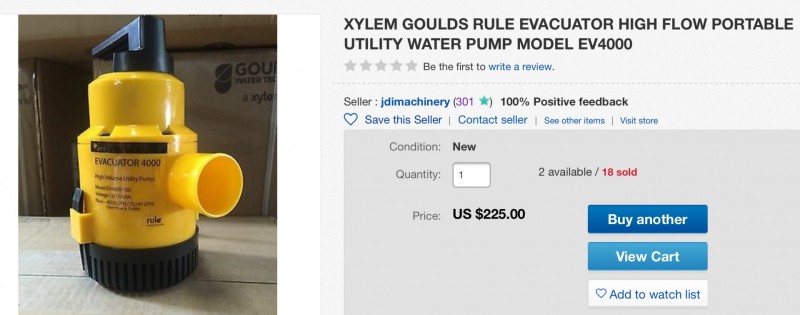

All the bad weather, snow and to many things I need to take care of no chance to get away for a trip to gold country, been watching tons of YouTube gold related videos on prospecting related stuff and the occasional Jeep roll over compilation just to scare me into not doing that stuff with my Jeep on the gold trail?. Lots of ideas on the web for idle hands to foolishly venture, not that I don’t have anything to occupy my time, but a little sucking device somehow seemed like a good idea, so off I go... I’ve been building my little Jeep friendly recirculating sluice and thought I would try making a nozzle for use with the pump I already own, just a few pipe fittings and a little part here and there. I already have a Keene high banker setup and 90gpm Honda pump I can’t use in California, but something small for Jeep travel where it’s ok might come in handy, so I build the first one paying attention to everything I can think of to reduce friction and any head pressure and the little bilge pump was inadequate for the task. searching the web for 12v pumps it’s hard to find anything that produces both volume and pressure at a reasonable price, the rule 4000 utility pump was the most powerful at 66gpm open flow and max lift of approx 30’ with over half its rated volume at 15’, but at a cost of 20amp hrs power consumption, they even made a two stage model rated at 134gpm same rated lift. Only problem the rule evacuator pump line are discontinued and I could only find one seller in the US that still had 3 in stock, every one else was out and the product is no longer listed one the manufacturers web site. I passed on the rule4000 and found a reasonable priced 1000 gph utility pump with a rated max lift of 7m out of Korea and ordered one, it won’t arrive until sometime in April I find out so we’ll see but I suspect it was a waste. I should have stopped reading about water pumps, but didn’t and found another 12v pump that looked better with more volume than my bilge pump or the Korean pump and with a rated max lift of 7m burning only 13amp hr from my battery and ordered it. superior pump came today and I outfitted my nozzle with the new pump along with a water proof power switch and cigarette lighter socket power cord, even with the power of this pump (1/4hp) the suction is inhibited by the discharge restriction and lift enough to make it not quite just enough suction to be practical, however pumping directly into a container without the lift it will suck dirt and gravel more than enough to be worth trying out for bedrock cracks. Everything but the battery weighs 8# total out of the water and in the water it’s slightly negative buoyancy keeps it on the bottom without feeling heavy it also feels fairly well balanced. Before the superior pump arrived eBay kept nagging me about the rule4000 and I still couldn’t find a replacement for this now discontinued pump, so with only the 3 left I figured it was only a couple hundred and I’d might regret it more later if I passed cause I’m on a mission now and pulled the trigger on the rule pump, estimate it arrives on Friday. At over twice the power and capacity of the superior 12v pump it should pump material into my little highbanker if I get a larger battery. Anyway more to come...

-

So i love building innovative equipment for prospecting almost as much as i love prospecting. I usually try and build things that solve problems that i see with current designs or builds that help me get to hard to reach places. One of my biggest issues with any high-banker/ mini trommel set up is that regardless of the size of the hopper and depending on the angle you would either have baby feed material in from a five gallon bucket or you would be clearing off the grizzly bars constantly with your hands or a combination of the two. Ive noticed most of the big equipment fed plants and trommels use a vibrating feed system to provide a nice even feed of material regardless of the amount dumped in the hopper. But i have found that no one makes a system like this for smaller equipment and small scale prospectors, so i decided to build my own small version and see how it works. This video is the first time out testing my build and i will say it needs some modifications, but the overall concept worked amazing. My buddy and me couldnt keep up with feeding it, probably need about 4 people shoveling into it. It will take up to three 3/4 full 5 gallon buckets at a time. Should be an awesome tool for leveling old tailing piles, and when paired with a mini trommel should really help with emulsifying clay. Hope you all enjoy the video, please comment and let me know what you think, and like, share and subscribe as well!

-

So I finally got around to ordering a bilge pump and gathering up spare parts at home along with a couple trips to Home Depot to assemble my little recirculating high banker project. The pump I ordered is a 1200 gph 12v Atwood tsunami submersible bilge pump that seems to deliver adequate water to operate my setup although I have not had a chance to run any dirt yet. The hopper is made from a plastic desk top office bin outfitted with 1/2 copper spray bars that have 26 3/8 outside diameter nozzles to wash dirt through 1/4“ SS mesh. The 3 bins probably hold around 15 gallons of water and with the small container inside the 1st trash bin have 4 separate tanks to separate particles in the water from the pump, hopefully keeping the water reasonably clean. The jump starter battery pack claims to provide 90 amp hours that should give me 15 hours run time with the little pump at 50% discharge on my battery before needing to recharge. . still a tiny bit of tweaking to control any water leaks. the pump and most everything fits inside the trash bins for storage and transportation.

-

The wife and I sometimes like to bring home some dirt from the foot hills and run it on through a recirculating sluice at our leisure...(after work on our front porch with a beer) if you get the picture. The one I built several years ago is getting tired and I was wondering how others set theirs up? is there a better sluice set up already made from the factory? I've been hearing about this gold cube sluice? any and all recommendations are appreciated. The pic below (copied off the internet) is kinda like how we had ours set up.. strick

-

When i bought the house i didnt realize that there was an old gold prospect in the backyard. An old history report from around 1860 says that an 18 inch wide quartz vein prospected by open trenches and that pan washing the crushed ore yielded good results. A pan of the soil pretty much always give 5 to 20 colors and abundant magnetite crystals. I have metal detected the area a good bit and have found plenty of hot rocks and hot ground but no detectable gold yet. I will be doing a loaming program and trenching to located the specific gold bearing vein. Then maybe decide to dig a root cellar. lol In the video i run a highbanker in the little feeder close to the old prospect and about 100 yards from my back door.

-

1st Off, Happy New Year to all, may Good Health & Much Wealth come your way this 2019 !!!!! 2nd part of 3, different creek same Highbanker. Used as a dredge this time no pontoons & very little water. This was on a friends claim year or so before I stake mine approx. 2000 ft above. A dam was built up above and redirected creek water into a pipe line to feed water into a lake for water supply to a hydro electric plant on a lower lake. Yes I have mentioned this in other post. So 1st some prospecting was in order to decide where to dredge. I was lucky & found a corner in creek that was actually a decent hole with the bedrock coming up at end of hole, so making dams was a bit easier, one dam to hold bck what little water the feeder creeks & rain run off would supply, and then a dam for pump supply water. Needed 2 dams because 1 dam would get suck up to quickly when dredge nozzle & water pump ft valve in same hole & I needed to keep my visibility to dredge. ( see photos ) Now my H.B. Sluice M.T. into my intake pump water supply so to not suck up big dirt into ft. valve then into my shaft seal I went shopping for a ordinary desk trash basket with small enough holes to keep shaft seal destroying materials to a minimum & water flowing to pump. At the end of each day I would have to dig out 2nd hole to make sure I was ready to dredge next day, but it also was a great way to check and see if I was loosing any gold out my sluice just by randomly panning as I dug out hole and used material to build up dams. This system worked great, the more I dredge in dredge hole the deeper the water got. It was actually getting to deep to snorkel dredge but this creek the water is crystal clear & the gold would smack you in the face as it fell out of gravels into your nozzle. Wasn't getting rich, but my overhead for the day ran about $40.00 & I would have clean ups of 4 to 5 penny weights averaging $60.00 a penny weight you do the math. Dredge time approx. 6 hrs. a day. Unfortunately I never did get to the bottom of hole, pulled my equip. next spring, my knees wouldn't let me climb up & dwn the 380 ft canyon wall And I was now a claim owner with very little climbing involved. So this is just another use of a Highbanker. Next the 3rd & final part. And a special shout out to my best mining partner ever Rocco may he rest in peace & watch over us all, he would actually check on claim owner once or twice a day & come right bck to watch me. I hope this answers any questions if you are considering a Highbanker I really liked my Proline 3".

-

I have had some folks asking me how I liked using a Highbanker and the different uses. So I'll show a couple examples. I was using a Proline 3" ( That I bought from Bob at A.M.D. ) with and without pontoon package. The 1st photos show me using it as a what I call a true Highbanker, I mounted the motor/pump on a treated pc. of plywood and drilled 1' holes around boarder so I could get it close to creek and tie it off so it wouldn't vibrate into creek. Then I would level off small area to set up hopper/sluice bx., and would use a oversized milk crate to catch tailings and spread them out to make a nice working pad. Next the digging and classifying into 5 gal buckets, I used the large classifier and dumped onto a tarp next to H.B. approx. 55 buckets. I believe that is close to a yard of material. Start up pump run material and repeat. Photos show a good representation of this type of use as well as some tools of a Digger. And at end of day if weather to stay dry I would cover Motor/Pump with small tote and call it a day. I would take cons hm. and see if I had a good day or just a really good day of hard work. The dog was my best friend and bear watch Rocco...…. Next dredging with H.B. not using pontoon package.

-

Just wondering if any Forum Members have tried this Pan? Just found it today. ? Ig

-

Some buddies of mine that were dredging down streem from me last year let me use there letrap to do a cleanup from my 6, and man it worked great! Not a spec in the taillings and ive tested several other sluices and has found a disapointing amount in the tailings of others. I been keeping a eye out and have only seen one online shop have 2 in stock. Of course i didnt have the money to blow at the time and they both sold quick. Are they discobtinued?

-

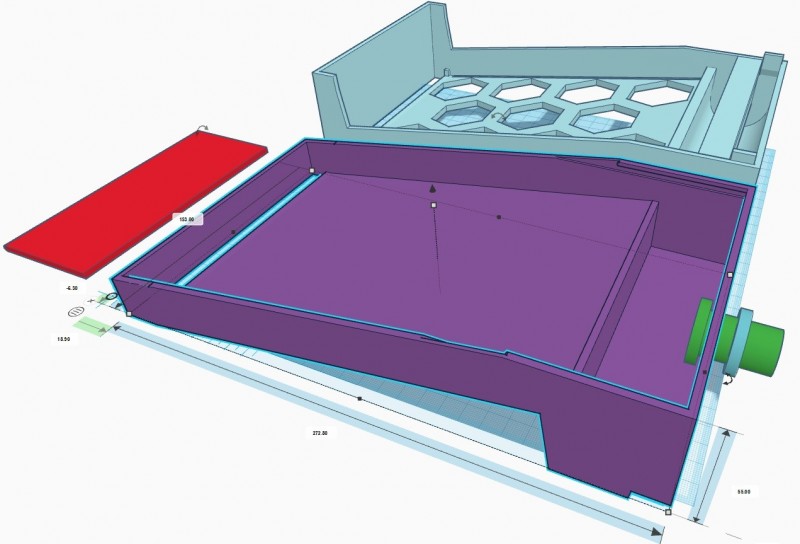

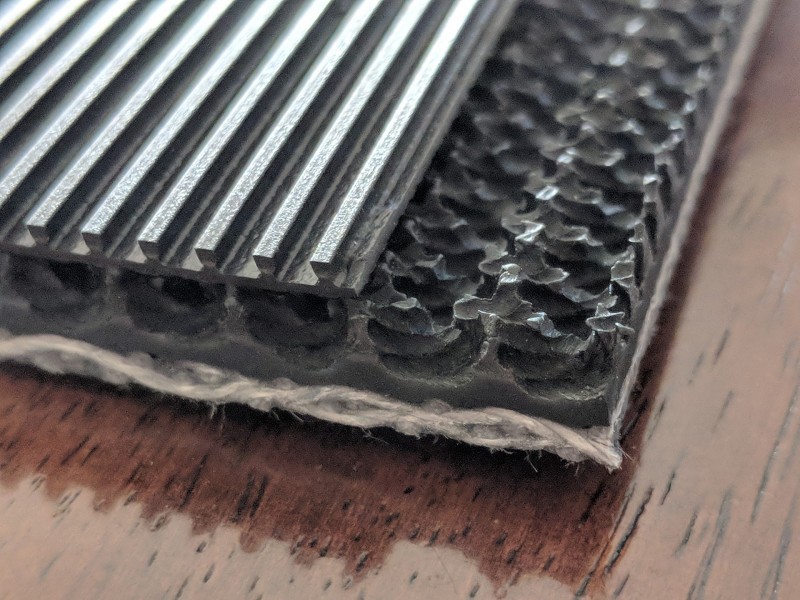

So, after playing around with a few ideas, I figure it's time to go ahead and make a larger scale sluice. No tiny 95GPH flow, this is going to be 500GPH. That's just over 5 times as powerful as my previous "pocket sluice". This is basically a small Gold Cube. Half the width, and scaled down in some areas. This one is designed to take real gold sluice rubber matting. I bought two types, one is generic "High-Low" matting that's 2.3mm tall. The other is "Vortex" matting, and it's 7mm tall. The trays I have are designed to print with minimal supports and material, hence the honeycomb grid. There is a little angular lip at the top of the matting area that keeps the top of the mat in place, and places the water and material flow completely onto the mat. The little pegs at the bottom keep the mat from sliding down, and and small enough to not impede water flow in any meaningful capacity. The underflow section at the top is actually the exact same dimensionally as the Gold Cube, so that the water flow works correctly. Under the foot where the underflow is, is a cutout that fits into the raised pegs at the top of the bottom end, so they can stack neatly. There is only 0.3mm of play between the parts, so that it's a nice, tight fit. The top tray, or "slick plate" is the same general idea, and has a 9 degree angle, just like the matting tray. The red lid slides into the slot around the top, and creates a tight sealed box that directs the water flow. It has only 0.3mm of clearance. The back of it will end up having a threaded tube, 3/4" to allow a bilge pump to be hooked up to it. What's not pictured here is an additional piece that directs water flow down to prevent excess splashing and uneven output.

-

I found some good gold in clay. Sticky, greasy stuff but shows promise. So I ask you old sourdoughs, what is the best way to process this material? I have been smooshing it by hand and then panning but it's not very efficient!

-

This is a 3D printed blue bowl version 1, it worked amazing for doing my last big clean up and sucked the sand away very quickly. I didn’t want to pay an arm and a leg so I built my own, leave an e-mail if you want the file. The whole project cost me less than 30 bucks or so. Parts: -172 GPH Pump -3/8 Tubing -On/Off Valve -12 #10-24x1in Screws -9 #10 Washers -Rectangle Tub -Small Bucket -Printed Parts

-

Well, as far as I can tell, it's the smallest FUNCTIONAL sluice box. This isn't a cute scale model to look like a neat paperweight. This thing actually WORKS! Let me know what you think! This has taken me well over 4 months to develop past where you saw it last time. I still have a few minor tweaks I want to do to it, but all in good time. As long as you can spoon feed it small enough material, this will work for you. I guess this would be more suitable for processing concentrates, but it should still be a hefty worker! Features: * Self-contained power (4x AA rechargeable batteries @ 1350mAh each) * 3x 120 LPH micro pumps @ 6volts each * Self-recycling water system * Can be used as a single or double tier system * Sluice trays are set at 8 degrees * Removable riffled drop-ins (currently printed in green) (upgradeable/swappable) * Debris catch bin for removing excess material from the basin * Scotchbrite scouring pad used as a particulate filter to prevent pump clogging * Fully disassembles and packs into itself for painless transportation * Watertight, isolated battery compartment won't get wet from splashes or overflow * Drain holes to prevent water buildup around solder connections to pumps, and in storage area * Spare storage area can be used for rubber mats, vials, filters, etc * Riffled trays (3D printed) designed for use in this system with its specific flow rate/angle * Quickly comes apart for cleaning of the trays or storage * Currently takes 687.52 grams of PLA filament @ 1.75mm (52 hours to print on my settings) Things I want to improve in my next version: * Isolate the pumps better so they don't suck up material or silt * Raise the edges to allow it to process larger piles of material without spilling over the sides of the trays * Make a better trap to catch the waste material, rather than let it build up in the main basin * Design riffle drop-ins that are more easily removable * Possibly design different types of riffle drop-ins This one was just before this 2-tier version, when it was at a single level. Check out this point in the video, where a pretty good size nugget shows up!

-

Does any place still make and sell the rubber Knudsen bowl liner? Google seems to just lead to a bunch of spam pages. I acquired an old bowl and the previous owner thought there was a store in Reno that made or sold them but I haven't had any luck locating said store. Also semi-related I am rebuilding an old jig, never used one before, and I was wondering what people use for shot? Do you just buy steel shot in bulk like from an ammo place or is there something cheaper and better to use specific to jigs? I see tungsten shot available for jigs but it's the same density as gold more or less so I'm having trouble seeing how that would work, especially if I want to save the black sands too. I'm curious what people use here?

-

I ran 2 Ozt of my -50 mesh, black sand concentrate through the Blue Bowl. It came out to .5 gram. This was 2 oz dry concentrate off the top of the container, I suspect the bottom my be richer after all the jarring around for the past 2 weeks. I'll send the Blue Bowl tailings and about a couple lbs of concentrates to Rege in PA to see what his Miller Table can do. If I could fill the back of my truck with this stuff it might be worth something, but as it stands not really a game changer. Still waiting on Rokon parts, then back to Gold Country. I've got a new plan, of course. 118 degrees here in Sunny Yuma tomorrow, but it's a dry heat. Yeah great!

-

I've been trying to come up with a unit to recover gems dry, but finally realized that the "granular convection" problem can't be defeated. In the process of building and trying various ideas, I came up with this unit. While the dry recovery of gems requires some very tight classifying, and thus isn't practical, I tried it for gold, and was simply amazed at its abilities for heavy metals. I have tried it on all sorts of raw materials, running bank feed at roughly 2" minus, and have yet to find a material it doesn't work on to one extent or another. I ran it dry...no water, on damp material at the LDMA Blue Bucket outing near Baker, Oregon a few weeks ago, and recovered flour and black sand from old tailings from previous outings. Running wet, the day before, on new material I recovered very near 100% on black sand and gold in front of several witnesses. They suggested re-running the tails, and zero black sand, or gold was found. Last weekend I attended a local club outing at Salmon, Idaho. The material was a heavy clay with lots of rocks....not a fun material, at all. At the common dig, one of the guys next to me, running a highbanker, mentioned that my little unit was handling the clay really well. I was the only person running 2" minus directly into the machine, and the rocks were agitating the material so the clay broke down, and the rocks were mostly clean before they went out to tails. The day prior to the common dig I went down to the locale the common material had been hauled from, and ran the material dry. This was a nasty, damp material. I expected nothing and was surprised to see both black sand and gold when I did the cleanup. Certainly I lost quite a bit, but any recovery working dry from damp material is an accomplishment. This unit works wet or dry. Very little dust running dry. Very low water requirement when running wet...roughly 50 gallons/hour. The full utility US Patent has been applied for. You can see the prototype running at Bonanza Bar on the Snake, along with pics of the recovery here: Jim

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)