Search the Community

Showing results for tags 'recovery devices'.

-

A decent summary of placer gold recovery methods with good illustrations. A good place to start for beginners so pinned here. 5mb pdf download, 29 pages with excellent references. The reference list on page 29 should be followed up on for more detailed information - Google is your friend. https://www.conservation.ca.gov/cgs/Documents/Publications/Special-Publications/SP_087.pdf CONTENTS INTRODUCTION 1 CONCENTRATION OF PLACER GOLD ORE 2 SMALL SCALE RECOVERY EQUIPMENT 2 Gold Pan 2 Rocker 3 Construction 3 Assembly 5 Operation 5 Sluices 6 Long Tom 7 Dip-Box 8 Shaking Tables 8 Portable Processing Equipment 10 Amalgamation 10 DRY PLACERS 10 Dry Washers 10 Air Tables (Oliver Gravity Separator) 11 MODERN RECOVERY EQUIPMENT 12 Pinched Sluice Systems 12 Spiral Concentrators 13 Rotating Spirals 15 Helixes 15 Jigs 16 Fine Material Separators 20 Bartles-Mozely Separator 20 Bartles CrossBelt Separator 21 Centrifugal Concentrators 21 Bowls 21 Knelson Concentrator 22 SUMMARY 22 OPERATING MINES 23 Hammonton Dredge 23 Hansen Brothers - Hugh Fisher 25 Bear River 26 Greenhorn Creek 26 TRI-R Engineering - Stinson Mine 27 SELECTED ANNOTATED REFERENCES 29 While this publication does a good job summarizing everything from the gold pan to some pretty sophisticated recovery devices, the one thing missing completely is the gold suction dredge. For that, see my article below on that subject: Suction Gold Dredge Basics For a more in depth look at suction dredges, see Keene’s Suction Dredging - Understanding the Basics

-

Found this publication recently: “How We Get Gold in California” by William V. Wells (published 2010 by VistaBooks.com). Wells was apparently an original 49er that returned to the California goldfields in 1860. He documents the gold placering equipment and techniques in use in 1849 then again in 1860. Of interest is that both the Long Tom Sluice and Dry Washer were in use in the California Goldfields by 1860. Plus much more.

-

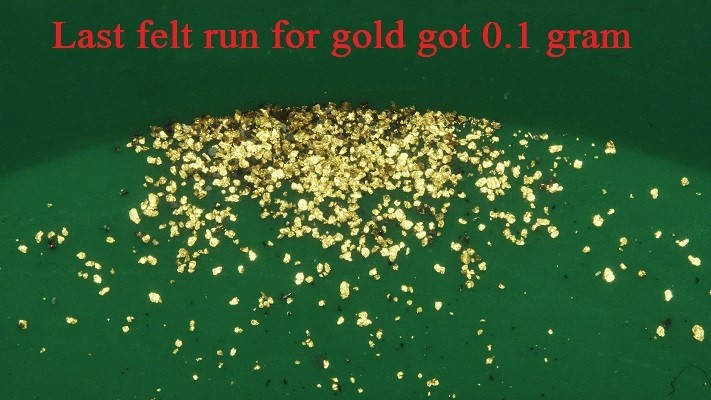

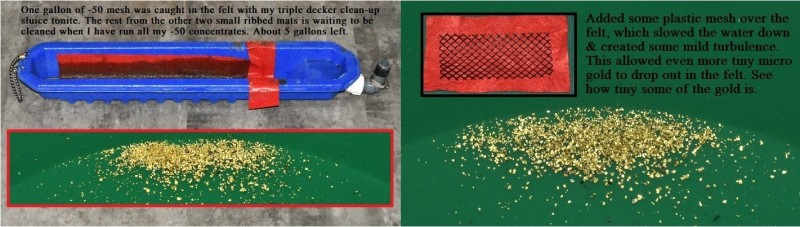

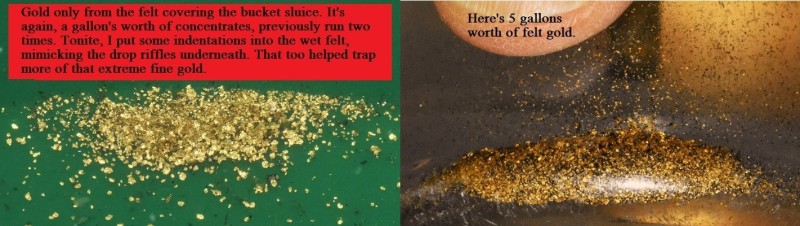

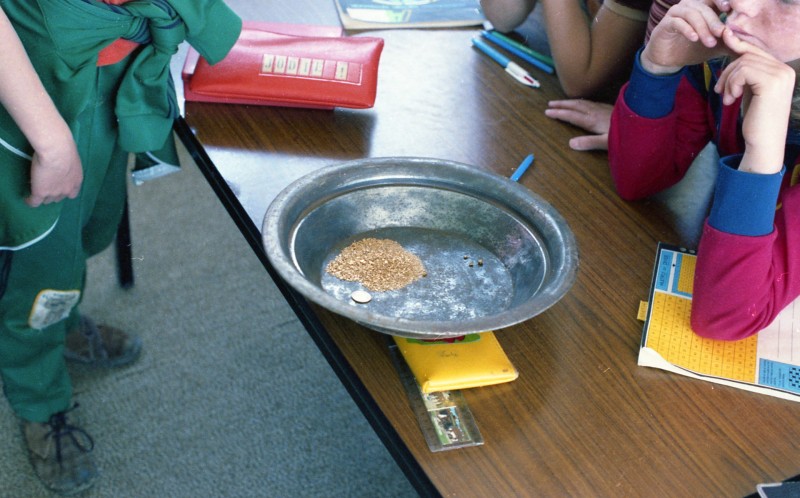

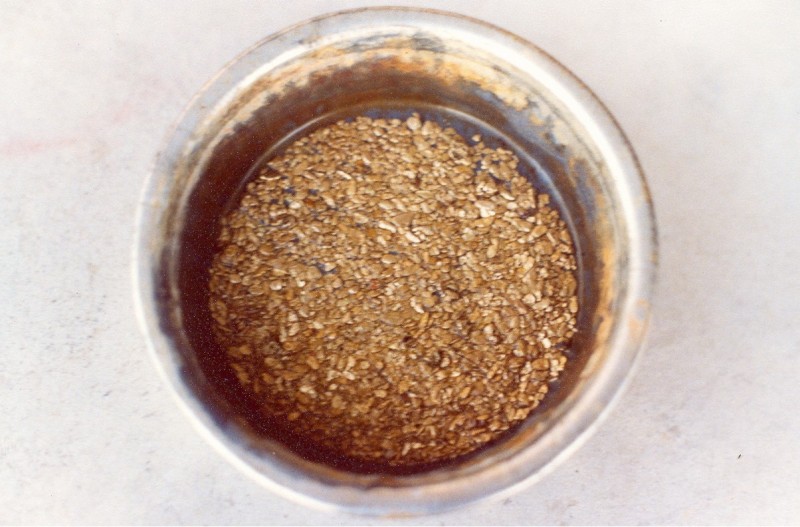

My final felt run was completed. After running this years concentrates 7 times, my 7th and last felt run got 0.1 gram of gold. My purpose of this experiment was to see if felt could be used in the final cleanups of concentrations from gold prospecting. I was pleased with the results. Not only will felt bite and hold a lot of gold, but please look at how tiny some of the micro gold it caught. Could felt be used to clean up cons? Absolutely! To remove a good percentage of tiny micro gold? Absolutely! Could it be added as an extention to your sluice? Absolutely! Could it test your tailing for gold loss? Absolutely! After all my concentrates were reduced to -50 mesh, the felt managed to get one gram of gold out of the pre-run 10 gallons of original concentrates. What are your thoughts? Any other uses come to mind for your set-ups? Let me know. Last nights final run.....it still caught gold. I guess you never really get it all. Notice how tiny some of the micro gold is. Here's what half my felt-concentrates looked like.

-

Picked up some new classifiers from a gentleman up in Cottonwood AZ, Dave Garner is the name of the person, and I will say these things are heavy duty and very well made stainless steel classifiers, they work well with 5 gallon buckets, four different sizes 1/2 inch,3/8 inch, 1/8 inch and 1/16 inch, the 1/16 inch also works great as a bowl to drain water off of spaghetti and salad because it is food grade, a food strainer is what I kept the 1/16 for as I cannot see classifying dirt down that small, I have the Gold Fox Mini Monster with the Mini Trommel that I run material down just for a fun project at home I carry 2 or 3, 5 gallon buckets out with me when I am able to go out and bring it back to my house for days I cannot get out and detect.

-

Dang it anyways! While doing my final back-panning in my clean-up pan, I discovered a little hungry bead of mercury which ate up some of my flour gold from todays dig. Oh well, at least my ball of mercury amalgam is growing in size. Anyhow, my buddy and I went out to do a little prospecting. I used the mini California drop riffle sluice, and he used his mini Le'Trap. Going to sleep well tonite. \

-

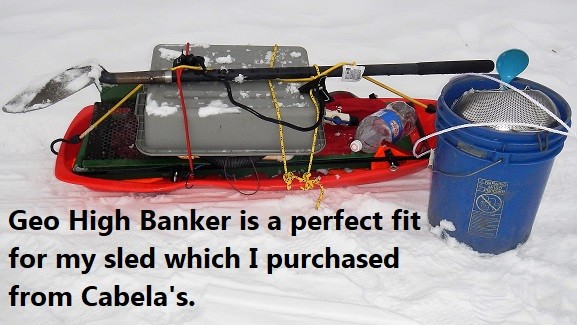

I have noticed a trend where sluices, highbankers, hoses, batteries, pumps are becoming smaller, lighter, more affordable, more popular, and nearly all manufacturers are offering a new line to include these. At one time, bigger was better. 12" wide, 12 foot long highbankers were promoted as getting it all. And, maybe often times it did. However, the downside was it was heavy, not very transportable and the amount of concentrates to process was incredible. Fast-forward to today. New materials make for very light, more portable equipment, along with smaller pumps. People now realize a 6 or 8 inch sluice works well, especially with new types of riffle and matting systems. Gasoline pumps have often times been replaced using bilge pumps, with new, light weight lithium ion batteries. The final, screened remaining concentrates can be taken home in a plastic bag. The equipment can be transported in a back-pack, a wagon or other light trolley. You can hike into areas now, not available without a boat or roads to get a much higher gold return. With science & technology producing new riffle deigns, resulting in better capture rates, smaller, leaner cheaper just might be a better choice. What are your thoughts?

-

Good afternoon, I'm Scott Posey, the Mining Manager at the new AMDS Mining Superstore. I'm a lifelong avid gold dredger and prospector. Our new facility is open now and I hope you will stop by and visit. I am traveling to visit with Mark Keene at Keene Engineering next week. We will be discussing new product development and ideas for the new store. What would you like to see? How about a trommel fed by a mini excavator? Do any of you have a mini excavator, and if so, what is it's capacity? Any questions for Mark in general or other suggestions? I'm really interested in hearing from you. AMDS is becoming the sponsor of this particular forum and I plan to be here regularly. If anyone has questions, well, I am the manager so get a bit busy at time, but please be patient and I will get back to you. Thanks for taking a look at this, and hope to see you soon. Scott Posey, Mining Manager AMDS Mining Superstore 3032 Commercial Drive Anchorage, AK 99501 907-277-1741 scott_posey@akmining.com

-

I haven't posted here for a while. I started a Face book Le'Trap and drop riffle highbankers and river sluice discussion group last year, so that has been taking up a bit of my time. Anyhow, Steve can probably relate to this. Headed back down to the North Saskatchewan River (Edmonton Alberta) today. I took my favorite drop riffle highbanker, the Geo (geometric) highbanker. Ice had formed along the banks, so I had to dig further out in the current in 2 feet of water at times. After a couple of hours, I started getting cold, so I shut it down and did my one cleanup today. It was above freezing outside, so my equipment did not got seized up from freezing. The electric bilge pump did however run a little bit slower then usual. Over all. it was a successful day. I did get some vitamin "G" today and I will sleep well tonite!

-

My buddy trout fishes in a little stream that is a mile as the crow flies but 3 miles on foot from the road. An old government document said traces of gold in 1904. He just wants to confirm gold. A speck would have him crowing for longer then i want to think about?. I would think panning would be good enough. It's 28x10 inches. and a few dozen specks in price

-

Hey everyone, I have posted these photos on another topic, but I thought I'd start a new topic. Sniping is relatively new to us down her in Tasmania, and for me I've only done two summers so I'm just getting started. As a beginner I thought I'd start the topic and let others give us the benefit of their experience.

-

-

Due to a late snow melt in the mountains and above average rain in Edmonton, my favorite spots on a local river are still under 3-4 feet of water. I went to another another nearby river not affected with mountainous spring runoff, did some sampling, only to find 3-4 specs of gold per pan. Somewhat disappointed, I grabbed some grass and pulled it out with the roots. A quick check showed about 30-40 specs per pan. Who knew? So, I spent the rest of the afternoon washing roots. I made a quick video showing my process.

-

From time to time I like to take things back to reality and talk about what I love - mining & exploration with the emphasis on exploration. I know this is a metal detecting and prospecting site but exploration using heavy equipment could qualify as prospecting on a larger scale. Maybe there are some people out there who have an interest in scaling up their efforts. So I thought i'd share what I have learned from 11 yrs of work on mining claims. I have used several trommels. One was a large home made job that processed about 40 cubic yds of gravel per hour. The last two I used were a Gold Claimer Pioneer 30 & a brand new Heckler Fabrication 2410V. The Pioneer 30 was very easy to use and did it's job withot any real issues even though it was an older unit. The sluice box was very easy to set up. After we constructed a pad to set it on we had it ready for water in less than two hours. It is towable as it comes mounted on an off road trailer. Very mobile and I liked it. It is rated for 15 - 30 yards/hr. We never processed more than the lower end of the range. One thing I have learned about the yardage ratings on most trommels is to cut them in half and if you know that going in you won't be disappointed. The Heckler Fabrication trommel was a beast. Everything on it is heavy duty. It is also mounted on a triler. The 2410V gives you a shaker hopper / feeder as well as the trommel. It is built to last but we had a few issues with jam ups as material entered the trommel from the shaker. it required us to keep a man on the back end dedicated to watching for rock & gravel jam ups because if you don't catch them quickly be prepared for an hour or more of shoveling out the hopper & sometimes even crawling into the barrel with a hammer. Not fun as the barrel is tight. Once again the rated yardage was about double what we achieved which was around 14 yards/hr. The yardage of each trommel matches up pretty close but the Heckler is cheaper and gives you a shaker if you buy the V series. The capture was better on the heckler. I think this was due to the shaker which had a pre-wash and a superior sluice box. Speaking of the sluice box on the heckler, it's a royal pain to set up. It has a short rubber sleeve that the box attaches to and a lousy hose clamp to hold it in place. Forget it. It wouldn't hold and it is very hard to get the box level while keeping the stubby rubber sleeve attached. We ended up chaining it in place. The first time we set up the Heckler it took an entire day because of the sluice box which drove us crazy and caused tempers to flare. The other lesson i learned about the mining aspect of trommels as opposed to exploration is that more yardage is almost always better. If your digging with a mid sized excavator and loading with a skid steer you are very capable of processing 30 - 50 cubic yards of pay gravel per hour. Skid steers work really good as pay loaders. They are fast and much cheaper to operate than a loader. If you're going over the 50 yard per hour range you may need to go to a loader. So it becomes very frustrating when you limit yourself to a 15 yard per hour trommel. When we processed gravels on one of our good locations we had to pump water nearly 2000 ft across a mountain. We used two three inch pumps in series to get enough lift to get over a 100 ft rise. One pump couldn't do it. Things never go as expected and it's rare to run all day withou stopping for something giving you an issue. Our last test run was at a location where hydraulic mining had stopped in 1860 & we were the first ones back in. We were able to run 50 - 60 yards per day and were averaging about an ounce a day. That's with a 15 yard per hour trommel. So you can do the math on a larger trommel. We leased that project out to a group in Nevada. Anyway, that's a little bit of what I have learned over the years. Living off grid on a mining claim & making gold is a feeling like no other. I think they call it freedom.

-

I'm planning on doing some gemstone prospecting here soon. I know I can more or less dry pan for diamonds and sapphires, but I'd like to move a bit more dirt, like 1/4 yard test holes in washes, 4-5 test holes a day. I need something light and portable (ATV packable). Lacking any other ideas, I'm just going to use my drywasher. Is there anything better than that?

-

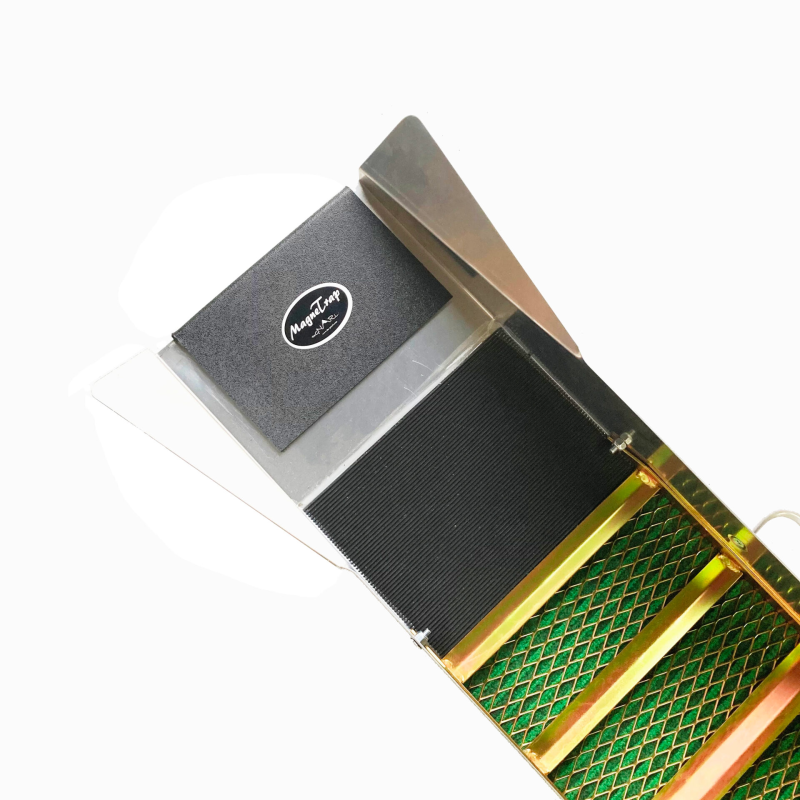

Has anyone used a Magnetrap before? It seems to be some new gadget for catching black sand before it enters your sluice Here is a video of it. Now, I love gadgets, especially ones that work so I'm going to order one for my Keene A52S. Our rivers have so much black sand I think I'll be cleaning it off after half a bucket of gravels, I can get 35 ounces of black sand in an hour of sluicing stuck in my sluice, I have to clean it out every hour in some rivers or it clogs up really bad so something like this seems a viable quick way to control the black sand. What I don't know is how much gold is going to get stuck in the black sand using it, when I clean out my sluice there is always a lot of gold stuck in it, if I use my magnet to remove the black sand from the pan I lose gold every time so I have to try pan out the black sand as well to make sure I don't loose too much. Something like this seems a viable option. If nobodies got one I'll let you know how it goes in a few months, no way am I entering the creeks or rivers for some sluicing in winter, I value my limbs. ?

-

I'm going to mount a super magnet to the bottom side of my pick. My question is: How far from the tip should it be mounted? The magnet is 1.5" diameter and the pick blade is 2" wide. As can be seen in the photo (sorry for the overexposure...), if I mount it touching the neck then the closest any part of the magnet will be from the blade edge is (4.5" - 1.5" = ) 3.0 inches (7.5 cm). Is that best or should I mount it closer to the blade edge? In case it matters (and isn't obvious), the use for this pick is aeolian placers (e.g. Rye Patch, NV).