-

Posts

778 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by Jim in Idaho

-

Looks to me like the batteries have the controller built in. Or are they simply stating what should be done when charging/discharging? Jim

-

NIce V's! First coin I ever found was an 1889 V. Found it while nugget hunting, using the GMT. Yours are in good condition. Jim

-

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

Gold / Quartz Specific Gravity... Question

Jim in Idaho replied to IronDigger's topic in Rocks, Minerals, Gems & Geology

I got 62.39 using this formula: (SG -2.65) x 19.3 / (19.3-2.65) x SG That result is 14.629/56.743, which gives .2578, or 25.78% gold, which equals 62.39 grams SG of the specimen is 3.408 Jim -

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

Gold / Quartz Specific Gravity... Question

Jim in Idaho replied to IronDigger's topic in Rocks, Minerals, Gems & Geology

Yup...it's a good thing to know how to do, especially for a prospector. It was a good refresher for me on calculating the portion that's gold, too. Jim -

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

Gold / Quartz Specific Gravity... Question

Jim in Idaho replied to IronDigger's topic in Rocks, Minerals, Gems & Geology

That's better, though I'm coming up with 88.34 grams of gold....LOL Jim -

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

Gold / Quartz Specific Gravity... Question

Jim in Idaho replied to IronDigger's topic in Rocks, Minerals, Gems & Geology

All the formulas in the world won't help if the specific gravity of the gold/quartz specimen is lower than quartz. If you divide 242 by 171, you get 1.415, which is much lower than quartz. If it was 2.65, it would be 100% quartz, so being 1.415 means either the water weight, as stated, is incorrect, or there is a large portion of lightweight mineral, or air, inside. If it's a gold/quartz specimen it has to have a specific gravity higher than 2.65. Jim -

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

Gold / Quartz Specific Gravity... Question

Jim in Idaho replied to IronDigger's topic in Rocks, Minerals, Gems & Geology

Yeah, as Walker said, must be a void, or large portion of very light rock within it. Maybe you should soak it in plain water overnight, and then do the water weight test again. If there is a void, and it fills with water, the water weight should be correct. If there is a void, and the water can get to it, you should see bubbles rising in the water. Jim -

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

Gold / Quartz Specific Gravity... Question

Jim in Idaho replied to IronDigger's topic in Rocks, Minerals, Gems & Geology

Yup...I get a density of 1.415g/cu.cm. That's lower than pure quartz. Jim -

.thumb.jpg.ac5e8ee36e43bcab745dbc623fcf1874.jpg)

A Once In A Lifetime Gold Find

Jim in Idaho replied to The Seeker's topic in Metal Detecting For Coins & Relics

Unreall..what a great find! Jim -

These jigs do not work well at recovering gold from black beach sand. It has been tested. If the beach sand is mostly quartz, it will recover gold and black sand as it would in a creek. But that iron beach sand is a whole 'nother game. Where the small unit shines is as a portable prospecting unit, you can take about anywhere, and use it wet, or dry. In larger sizes it will do well as a mining recovery tool. Jim

-

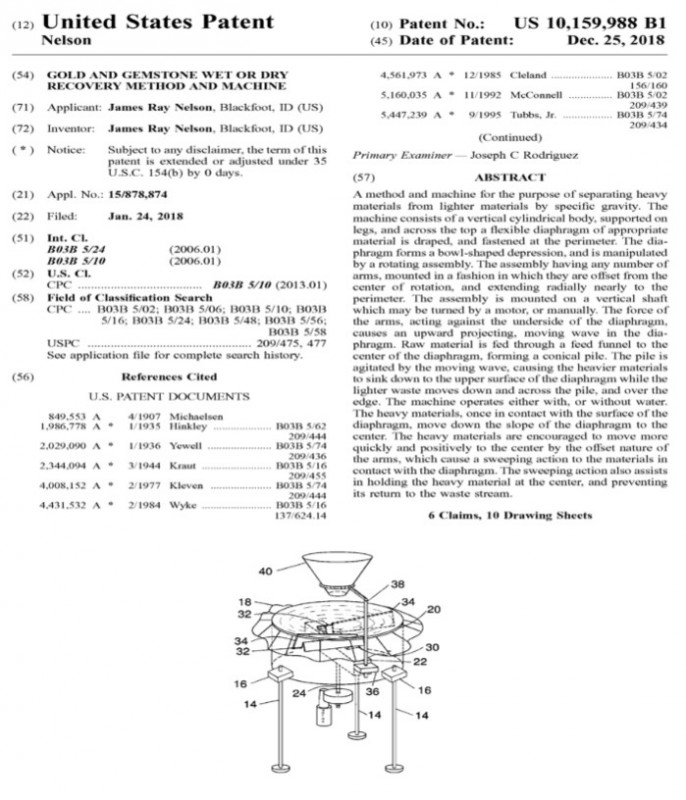

You can watch the prototype running, in the fall of '16 here: Sweep Jig at Bonanza Bar Personally, I like the aluminum model for it's light weight, and easy portability. I changed to the plastic-bodied units to save build time, and cost. But recently I decided to go back to the aluminum version. It will cost more, but I think it's better, and worth the small increase in cost. I'm still trying different versions. As for marketing, I'm hoping somebody will take it on a royalty basis. I turned 70 the 21st, and don't want to spend all my time in the shop building these. I've got 3 or 4 of the HDPE-bodied units ready to ship, and a bunch of aluminum on hand to build the newer version. There's no difference between them as far as operation. I'm planning on showing it at the Las Vegas gold show this spring. I included a pic of my unit setup at an old gold mine last summer. I was looking for pyrite crystals. Jim

-

LOL....that's a good one! Jim

-

I decide to take out the cons when I get tired of shoveling...LOL Seriously, I just do it at about 1-2 hours. The diaphragms, if using 6 mil visqueen last about 4 hours, so need to be replaced anyway. Visqueen is readily available at most hardware store, and is cheap, so replacing the diaphragm isn't a big deal. I think it works best with some gravel in the mix...just as you mentioned. 1/2" or 3/4" works great. When running wet, even 1" minus works fine. Running the bigger prototype (22") I just picked out the stuff over 2" and fed it. Still recovered the Snake flour(-200). Part of the patent is that the heavies move in the opposite direction from the tails, which is unlike any other device out there. I think that may be why it recovers really small gold so well. Also, the round shape slows the movement of the material which gives the heavies more time to settle.....another factor that favors fine gold recovery. Jim

-

Roughly 20 gallon/hour, DD. It depends somewhat on the material. Running wet increases the throughput, as does more granular material. Running dry, with a powdery material, slows the volume. Sandy material increases it. Running that powdery carbonaceous material at the Peg Leg, when I was trying to recover pyrites, I was only running about 12 gallons/hour. This is for the 18" diameter unit. Going to a 24" model almost doubles it. Jim

-

Yup...I've seen those videos. Up here, the native Americans believe it's bad karma to dig into an anthill. They also believe if you remove gravel from an anthill you should always put something back. I never dig up anthills...the surface tells me all I need to know. I'm trying to keep karma on my side...LOL Jim

-

What i want the slightly bigger (2") coil for is checking anthills, JW. Up here in the northern Rockies the harvester ants build large mounds. Inside the mounds are chambers where the ants can warm their larvae, and dry the seeds they live on to prevent germination. The ants go out as far as 150 yards from the mounds, and bring back materials to cover the mounds to prevent erosion, and damage. In the process, they gather the heaviest materials they can find. Bringing back the heaviest materials is a proven genetic trait. It's thought that this maximizes the benefits of the long range roving they do. So, the mounds are a great place to check to determine the minerals in a particular area. The reason I bought the Falcon is I was concerned about the ability of other detectors to "see" these really small pieces of gold or platinum. But the tiny search head on the Falcon means a slow process, so I thought maybe a 2" diameter coil would increase the search area by a factor of 4X without decreasing the sensitivity too much. I'm working on another project right now, so may not get to the coil build until December. I'll post my results. Jim

-

I bought a GM 24K and a Falcon MD-20. Bought the 24K because of it's advantages over the GMT. I prefer White's detectors because they work, feel good in my hands, and their customer service. The Falcon MD-20 I bought because I wanted a detector that could see extremely small metals. Neither of my purchases has disappointed me. I'm in the process of building a slightly larger coil for the Falcon. Jim

-

Yup...the diaphragm sags in the center, and the heavies end up there. You have to stop every couple of hours and empty the diaphragm so you can pan out the cons. The unit requires very little water. The water is just to make the damp, or sticky material let loose of the gold. Other than that, the water has nothing to do with the recovery. That's why the machine works either with, or without water. I've been surprised to see how well it works with even damp material with no water. Still recovers about 60%, and very small gold. The ones I sell are 18" in diameter, but I can build them to any size desired. The prototype was built in a cutoff 55 gallon drum...about 22" in diameter. The only place they don't work is on the heavy black beach sand. But, not many machines will separate gold from black sand, so I don't feel bad that mine won't either, though mine has not been tested on beach sand when running wet...only dry. The 18" machine weighs under 20lbs, so can easily be backpacked to where it's needed. Jim

-

YEEEHAA!!!! i was notified by mail today that my patent application has been approved! I need to send them a check for $250, and my patent will be issued. Only 5% of the patent applications are approved on the first run-through, so I'm really pleased to be in that group. I put 250 hours into the application. I'm really happy all that effort paid off. I may never make any money from the machine, but it's still nice to have a patent.

-

I've been trying to come up with a unit to recover gems dry, but finally realized that the "granular convection" problem can't be defeated. In the process of building and trying various ideas, I came up with this unit. While the dry recovery of gems requires some very tight classifying, and thus isn't practical, I tried it for gold, and was simply amazed at its abilities for heavy metals. I have tried it on all sorts of raw materials, running bank feed at roughly 2" minus, and have yet to find a material it doesn't work on to one extent or another. I ran it dry...no water, on damp material at the LDMA Blue Bucket outing near Baker, Oregon a few weeks ago, and recovered flour and black sand from old tailings from previous outings. Running wet, the day before, on new material I recovered very near 100% on black sand and gold in front of several witnesses. They suggested re-running the tails, and zero black sand, or gold was found. Last weekend I attended a local club outing at Salmon, Idaho. The material was a heavy clay with lots of rocks....not a fun material, at all. At the common dig, one of the guys next to me, running a highbanker, mentioned that my little unit was handling the clay really well. I was the only person running 2" minus directly into the machine, and the rocks were agitating the material so the clay broke down, and the rocks were mostly clean before they went out to tails. The day prior to the common dig I went down to the locale the common material had been hauled from, and ran the material dry. This was a nasty, damp material. I expected nothing and was surprised to see both black sand and gold when I did the cleanup. Certainly I lost quite a bit, but any recovery working dry from damp material is an accomplishment. This unit works wet or dry. Very little dust running dry. Very low water requirement when running wet...roughly 50 gallons/hour. The full utility US Patent has been applied for. You can see the prototype running at Bonanza Bar on the Snake, along with pics of the recovery here: Jim

.jpg.315e3bd3307813c91df4930dc3a75102.jpg)