-

Posts

42 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by AirmetTango

-

The Legend Software Update - Version 1.15

AirmetTango replied to HardPack's topic in Nokta / Makro Legend Forum

Yes, that was my experience using the beta (I haven’t updated mine to v1.15 yet). The beta DT seemed to utilize some sort of hybrid or overlay of the goldfield tones and standard tones, and it sounds like v1.15 didn’t change that. I personally didn’t like the way DT changed the audio tone quality especially at higher settings. The difference in tone quality was less noticeable at lower DT settings, but still definitely audible even at setting 1. Anyway, easy enough to check - just set DT to zero, and see if the audio goes back to the “solid audio” you’re used to hearing. For me, I heard no perceivable difference between the v1.13 audio and v1.14beta audio as long as DT was set to zero and all other settings were equal. -

Looks like you're right. Minelab issued v1.0.4 in September 2018. That's slightly before my time with the Equinox (I purchased in November 2018), and now that my memory is jogged, I'm sure mine already had v1.0.4 installed when I received it. I never updated mine until 2.0 was released in Sept 2019. Interesting that Minelab has wiped all mention of v1.0.4 off of the Equinox 600/800 downloads page. Clearly 2.0 is what they consider the starting point for the machine at this stage, which obviously would have all of the components of v1.0.4 anyway (though not mentioned in the notes for v2.0, for folks who may be updating older machines late in the game). Quite a few additional items were included in that first update - here's a screen grab from a Gigmaster video at the time of v1.0.4's release (don't get me started on Minelab's conceited, self-applauding lead-in for the "What is new?" section): Again, I'm not defending Minelab on this - there is absolutely no question that Nokta puts out more frequent and substantial updates in response to customer/user feedback than Minelab. My only goal was to point out that it isn't surprising that Minelab has not put out an update based on their own past behavior. Turns out we can call the 700/900 overdue for an update/patch even by Minelab standards. Unfortunately, maybe you've hit on the crux of the problem right there.

-

Just playing devil’s advocate here…I’m not intending to defend Minelab’s glacial pace when it comes to software updates, especially compared to Nokta. But keep in mind that the Equinox 600/800 was realeased in about January 2018, and the first software update (Equinox 2.0) didn’t drop until late September 2019, well over a year and a half later. It was almost another year before the final update (Equinox 3.0, July 2019) came out. So, projecting the same timeline onto the Equinox 700/900 which was released in late December 2022, you might be looking at September 2024 before an update for the 900 is “due”. Again, I’m not defending the slow pace, just pointing out Minelab’s track record…patience is a virtue when it comes to awaiting updates on the Equinox line.

-

I’m with you on all this! I really dislike both names. When I bought my Legend, it came with a hat emblazoned with “The Legend” across the front - no way I was wearing that! My wife saw the hat sitting on the table, and immediately deadpanned, “Wow…the man, the myth, the Legend. Snazzy hat!” 😄 As for the Manticore, I’ve taken to just calling it an M-core - I feel absolutely silly calling it a Manticore.

-

Pretty thorough chart provided in pdf format in the first post of this thread: https://www.detectorprospector.com/topic/21458-manticore-vdis/

-

Does The Manticore Need Another Update

AirmetTango replied to Chesroy's topic in Minelab Manticore Forum

Yes! A thousand times, yes!! I admit, I’d be willing to pay a fee to add certain features a la carte…I wouldn’t think twice about ponying up $15-20 to add pinpoint volume. $99 might be a little too steep for me for the mineralization meter…but my opinion is skewed because I’m fortunate to have mild soil in my usual detecting areas. Maybe $30 for the monochrome version? 😉 I know fee structures like that can be a slippery slope though….just look at airlines to see how you can get nickel and dimed for everything! -

Good eye! My first couple years on the Equinox 800, I almost always hunted with the horseshoe engaged. On the occasions that I didn’t, I always had the reference threshold in the background so I still had a gage on how polluted the soil might be getting. The last couple years, I started using what I called my “Poor Man’s 6-Tones” on the Equinox that used the threshold exclusively as my iron tone (iron range notched) while my first tone bin went to the bottom of the nickel range (gave me room for threshold as iron, then sub-nickel, nickel, trashy, IHP thru Copper Penny, and Dime & above ranges - total of 6 “tones” for a 5 tone setting). Anyway, the point is, I got very used to hearing threshold breaks as my iron tone. I’ve carried that trait over into the Manticore, which, to me, is essentially built on the same concept - a dedicated ferrous tone, and up to 5 dedicated non-ferrous ranges. Long story longer, I’ve been keeping the horseshoe disengaged w/reference threshold on during the majority of the hunt, and now engaging the horseshoe only for targets I’m stopping to investigate more thoroughly - the pronounced iron tone and red numbers jump out more noticeably on the iffy target, for sure. I’m pretty sure just having the reference threshold break as my iron tone on the Manticore was encouraging me to over-focus on the 2D display, especially since I was trying to learn what that was trying to tell me. You’re right, having the horseshoe consistently engaged while using ATHC might have helped snap me back into reality on how bad those targets really sounded while using that mode. As you and fishersari both suggested, I really need to put the 2D aside for now and focus on the audio quality and tone responses, and work the 2D screen in over time as the (valuable) supplementary tool that it is. Maybe I need to slap some black tape over it temporarily!! 😁

-

Great information throughout, fishersari - and thanks so much for finding and re-posting that response from Minelab. Very interesting to see that the iron falsing tendency seems to get more pronounced in soil with less mineralization - as I mentioned, the soil in my area generally has very low mineralization. It looks like I have to be much more selective about when I choose to run in ATHC, be more savvy about my supporting settings when I do, and be willing to dig noticeably more iron in exchange for some potentially masked targets if I elect to go after the iffier signals. @UT Dave @Jeff McClendon @TampaBayBrad @Dug D @Skull diver, Thanks to all of you for your very helpful replies - excellent advice and observations throughout, and I’ve already begun to implement many of your suggestions as I continue to learn the machine, and I’ve already seen a dramatic difference. Over the weekend, I spent a couple hours at one of the sites that was giving me so many problems in my original post, only this time I stayed in ATLC. It’ll probably come as no surprise to any of you that I had almost no falsing difficulties whatsoever. I’m not sure what my problem was when I had tried that mode on my first few hunts with the machine and I came away thinking it was falsing as often as ATHC - maybe I had my settings jacked up, maybe it was inexperience with the machine, or maybe I was just plain mixed up. But ATLC over the weekend was a night and day difference for me versus ATHC - I even came home with a ‘36 Merc from a pounded park. I’m a bit embarrassed that I didn’t think of going back and trying ATLC on my own before posting, but hopefully this thread can help other new Manticore owners as much as it turned the light bulb on for me…a lot of excellent wisdom in these follow up posts.

-

And yes, thanks for making that differentiation! I kept saying “truly masked” in my original post, but I do just mean co-located ferrous and non-ferrous…not necessarily two targets that are too close together for the machine to truly separate into individual targets. And maybe that’s the answer…my air test example above doesn’t represent true separation, because the machine was just seeing one target with confusing ferrous and non-ferrous qualities. Essentially a trashy single target. Just like a deep, large nail vs the surrounding soil matrix! Of course, in the field that’s going to be junk 99.9% of the time…might get purely lucky that one time in a thousand and get silver. Just tried those same two test targets in an air test, and pushed them a little further apart, and bumped the RS to 5: Again, just an air test, so I’m skeptical if this will hold true in the field, but the gap between the ferrous and non-ferrous is consistent and noticeable…much more indicative of two distinct targets. Perhaps this is a “tell” for in the field as well? If there’s no prolonged gap after circling, walk away? I’m probably just trying to read too much into the 2D trace again! 😄

-

Thanks for the insight, Dave - lots of good food for thought here! I hadn’t considered the recovery speed being a factor. I chose 4 because that’s been my basic starting point on the Equinox. On that machine, it usually was the best combination of excellent depth while remaining fast enough to not notice any real decline in separation. Target IDs didn’t seem affected at that level, but of course the Equinox had a much more compressed VDI. Anyway, at sites with more significant target saturation and/or contamination, I’d bump it up a bit, but it was fairly rare - I would generally tend to opt for a smaller coil before going any higher than 5 or 6 on the EQ800. But it looks like it might be worth experimenting a with little higher recovery speed on the MC. For audio, I’m using a slightly modified 5-regions All Tones. The most noticeable modification is the tone breaks - I have it divided into sub-nickel, nickel, trashy, IHP to dime, and quarter & up ranges. Less obvious is the flat tone range for nickels - I didn’t want a tone slope there because it was making nickels sound too iffy or less attention grabbing for my ears: My sites so far have been public parks, but they each have a history of prior use that lends themselves to heavier than normal iron nail contamination. I’ll definitely try ATLC again - with my increasing knowledge of the machine, maybe I’ll find the iron falsing tendency will be less noticeable when I give it another try, especially when coupled with a different recovery speed. Yes, my area seems to be better suited for higher sensitivities - mineralization is generally very low, and the MC does a fantastic job of killing EMI. I get pretty tight VDI numbers at sensitivities between 20-23 on non-ferrous targets uncontested by iron. VDI definitely seems to suffer as I get above 25. As I mentioned, I usually have to raise the sensitivity to bring out the iron range on many of these falsing signals. Lowering the sensitivity makes me concerned I would just get genuinely fooled more by tight non-ferrous tones and traces with no hint of iron. On the flip side, perhaps if I lower sensitivity into the teens instead, the falsing high tone iron goes away, but a coin/relic at a similar depth would still show up? I don’t have enough experience with the Manticore and deep coin/relic targets to answer that, yet. I agree, tuning for stability is key, and you get what you get on depth as a result. Up to now, I always just thought of stability in terms of EMI or lighting up too much micro iron at old home sites - excessive chatter meant I needed to back off sensitivity. The Manticore runs very quiet for me at 20-23 in most cases - I just have the constant occurrence of too many large nails masquerading as co-located non-ferrous targets. I suppose now I need to consider big iron/VDI stability, as well, and I need to drop sensitivity more than I think? Lots to consider and experiment with!

-

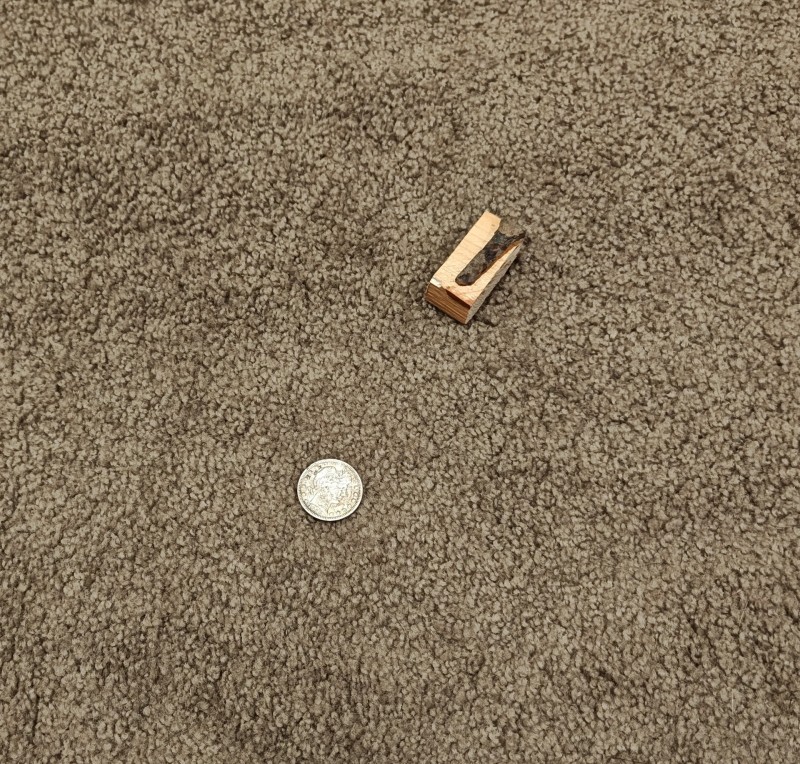

Apologies in advance for a very long post. I’ve only been using the Manticore (MC) for a couple weeks, and I only have about 15 hours on the machine, so I’m a long way from being a master. I’m coming from 5 years loving the Equinox 800 (EQ800) and 7 total years detecting experience. I’ve seen many comments from more experienced detectorists stating that the MC is really a completely different machine than the EQ800 - it’s not just a “souped up Equinox”. Despite hearing that, it’s hard to resist the urge to draw parallels and try to correlate my previous hard earned experience with what I’m seeing and hearing on the MC to try and speed up the learning curve….and maybe that’s why I’m running into trouble! Like many others, I’m finding that I’m digging way more iron nails than I ever have with previous machines. Here’s the iron from my last few hunts, versus a total of $1.47 in clad and 4 Wheat pennies: I don’t mean that I’m getting completely fooled - often the machine is providing hints that the target has ferrous qualities. I believe my problem stems from my hopes of unearthing a deep, partially masked coin. I don’t put a lot of stock into air tests, and usually don’t waste much time on them, but when I first bought the MC, I did a series of air tests to help me learn what the 2D screen might look like in various situations. The shape of the target trace on this particular set up stuck in my mind (Barber quarter next to a square nail): Swinging over the above combination resulted in these pretty distinctive target traces: I was pretty impressed with the 2D trace’s ability in the air test to clearly show strong evidence of a good masked target. Unfortunately, once in the field, I quickly re-learned that air tests don’t accurately reflect the behavior of old iron that has marinated in the ground for a handful or two of decades. It appears that every deep buried nail in existence creates the exact same target trace! Here’s an example of the traces for a deep target that I hoped was a masked coin, but turned out to be a solitary, large iron nail: In the case above, I was originally searching using sensitivity set at 20, using the “less is more” philosophy suggested in other posts to help avoid iron falsing issues. Once I isolated what I initially thought might be a good high tone target, I turned 90 degrees at sensitivity 20, and still had a centerline non-ferrous, but slightly skewed to the upper left. The photos above show me progressively raising the sensitivity…only at 27 did the target truly start to reveal what it really was…just a deep nail. If I left the sensitivity at 20, circled the target, and then dug, I actually would have been genuinely fooled by the nail. Here’s another field example of traces - this is the only one out of dozens that turned out to be a masked target…a clad dime co-located with a large iron nail. Again, my initial target discovery swing was while using sensitivity 20, and I raised the sensitivity to 25 as a checker to see if I could coax out signs of iron falsing (I might keep this permanently as a soft key). Honestly, the traces at both sensitivity settings looked similar, but all the photos were taken at 25: As you can see in all of the photos above, I’m using ATHC, which is the mode most prone to falsing due to the very low frequency weighting. But I had the same experience using ATLC - I kept feeling enticed to dig each of these type of iffy targets on the hopes of uncovering masked targets, and instead coming home with dozens of iron nails and one clad dime for my efforts. Recovery speed was set at 4 throughout all hunts. Don’t get me wrong - I’m not blaming the machine…it’s telling me these are iffy targets. I’m the masochist that’s deciding to dig all of them! Of course, all machines false to a degree, especially on deep nails. On the EQ800, I developed a technique that worked well for me - when turning on a deep target, if I had an iron tone at least 50% of the way around the target, I confidently walked away. If the high tone continued most of the way around, with say only 25% or less of the circle giving some iron, I would dig - sometimes I would still be wrong, but often times I’d get rewarded with a good target. I rarely came home with more than a one or two nails in my pouch, and rarely was one a complete surprise. With the Manticore, it looks like I may have set my expectations too high on what I can discern from the 2D trace regarding masked targets based on the air test traces. But also, the Manticore seems to high tone alert much more enthusiastically and more frequently on deep iron in general. With the EQ800 with F2 set at 1 or 2, I was stopping to investigate these kinds of “falsing/iffy” targets a handful of times across a couple hour hunt. With the MC, this is a constant task - every other swing is giving me a high tone to investigate and spend precious time evaluating…even as I learn to ignore these as falsing, it’s incredibly time consuming and eating into my enjoyment as they all inevitably get discarded as falsing, or worse, dug. All this is to say, I’m looking for any advice from more experienced MC users to help keep the false high tones more under control, and better recognize a truly masked non-ferrous target versus falsing iron. Overall, the soil in my area is extremely mild, as determined by the mineralization meter on a Nokta Legend (consistently zero bars on the mineralization meter). I’ll try ATLC again, but my first few hunts were using that mode with similar results. Lowering the sensitivity doesn’t seem to be the answer, because I’ve actually had to raise sensitivity in many cases to get an iron response (traces in the grey zones) - otherwise many of these falsing nails would have looked and sounded dang good. Increasing my ferrous limits likewise doesn’t seem to be the right answer without completely eliminating the chance to hit on anything even remotely masked. Thanks in advance for any advice!

-

Yep, that’s an unfortunate wording choice…free for only $80! Or are they selling a Simplex BT for $80 and you get the Accupoint free…sign me up!! 😁 Full disclosure, the full emailed ad clarifies the wording a little further down…and the ad was emailed multiple times because they saw the mistake and edited out the “free” in the Simplex section.

-

The Legend - Version 1.14 Beta 2 Test - Released!

AirmetTango replied to HardPack's topic in Nokta / Makro Legend Forum

I’m the opposite - although the Beta 1 seems to work just fine on my Legend, I’ll take Nokta’s advice and revert to v1.13 until the final update comes out...or at least revert to v1.13 just prior to re-updating to the final v1.14. I’m too worried that the update for the final version won’t play nice if I still have Beta 1 installed instead of an official version when I run the update program. I never got the chance to update to Beta 2 - it released on Friday I think, but I didn’t become aware of it until Monday, after I had already left for a work trip without access to my detector. By the time I got back home on Wednesday night, both Betas had been pulled down from their site. It felt like that old Seinfeld episode…”NO SOUP FOR YOU!!” 😜 -

New Manticore Defective Out Of Box

AirmetTango replied to Steve Herschbach's topic in Minelab Manticore Forum

Sorry you had this issue right out of the box, Steve, but as you said, at least the machine itself and the coil you really wanted to use was fine. Ludicrous that you had to pay the shipping for a failure right out of the box on a brand new, obviously in-warranty item. The only time I ever dealt with Minelab Service was with my out-of-warranty EQ800 control pod - I didn’t complain about paying the shipping when I sent the control pod in because the warranty was expired. I didn’t realize that was just what Minelab expects! At least they didn’t charge me the shipping on the new pod when I bought it (although I’m sure it was factored into the cost)…I assume they won’t send you a bill for shipping you a replacement coil?!? 😉 Agreed, Rob - except I’d make the case that it shouldn’t even matter whether they’re a big company or not…they should provide a shipping label and pay the cost on an out-of-box failure simply because it’s the right thing to do. I have a very small side business - it doesn’t happen often, but if ever I make a mistake or there is a problem with my product, I eat the cost of making sure I fix it to my customer’s satisfaction. It’s good karma as well as wise business, in my opinion. Mistakes and problems are going to happen - it’s how they get dealt with that speaks volumes about a person’s or company’s character. -

Minelab Manticore Hardware Version

AirmetTango replied to Steve Herschbach's topic in Minelab Manticore Forum

-

I agree, the tech is definitely approaching it's ceiling, and I've been very happy with my EQ800 for the last 5.5 years. My main complaints involved build quality issues much more so than performance. To make a long story short, I needed to replace my 800 control pod two years ago, so I decided this year was the year to look at moving on to something different, while I could still get good resale on the machine with a year of warranty left. I looked at the EQ900, but it didn't seem to offer enough (if any) improvement for the cost, and I didn't like some of the reviews from other detectorists that I trust - a few of them were previous 800 owners, and several sold off their 900s or went back to the 800. The Manitcore was appealing but I couldn't justify the cost for the potentially minimal gain in performance. I decided to try a Legend starting in January - I wasn't expecting an increase in performance, just an increase in build quality and roughly equivalent performance, and at a much better price. That's essentially what I got for the investment, and the Legend works very well - though I'd make the case that it's performance isn't quite the same in some areas that are important to me, and I'm not convinced (after almost 100 hours) that it's the machine for me. Anyways, the price drop on the Manticore was enough to entice me - if it was at this price point in January, I would have bought it over the Legend without a second thought. Pulled the trigger last night. Once it arrives, I'll suddenly have three detectors when I've always just had one, and I'll suddenly have an irate wife! But if the Manticore provides better build and even marginal gains over the EQ800 as it seems to promise, then it'll be worth it to me - I'll finally part with the 800, and the Legend will likely get sold as well.

-

The Legend Beast Mode Demonstration

AirmetTango replied to Nokta Detectors's topic in Nokta / Makro Legend Forum

Along the same vein, I would have liked to have seen how some of the other settings (Recovery Speed, Iron Filter, etc) were set for the Park/Field modes in the Nokta video. Maybe it’s safe to assume they were left at default settings since they weren’t specifically mentioned? Lower recovery speed in the original modes can definitely improve detection depth in many situations. Beast mode obviously has its own detection limit for a given soil environment, so it would be interesting to see how the full settings compared in the video for reference. (Edit: Nevermind - on rewatching the video, I see the recovery speed was specifically mentioned…don’t know how I missed that!) Regardless, thanks for the video, Nokta - it helps clear up many questions. -

Legend Iron Filter Stability Setting?

AirmetTango replied to Zaj56's topic in Nokta / Makro Legend Forum

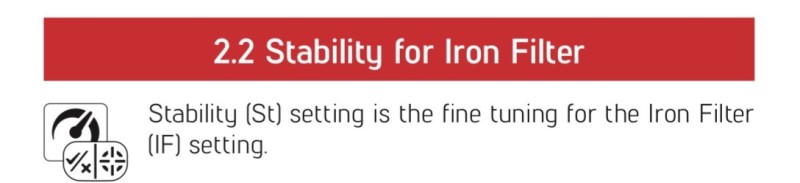

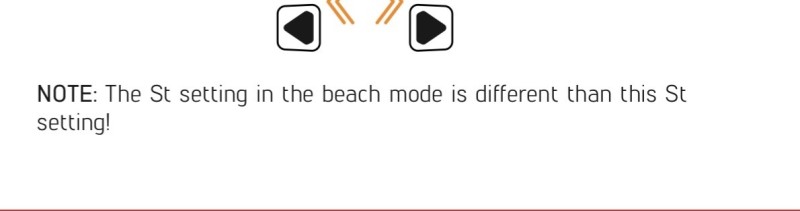

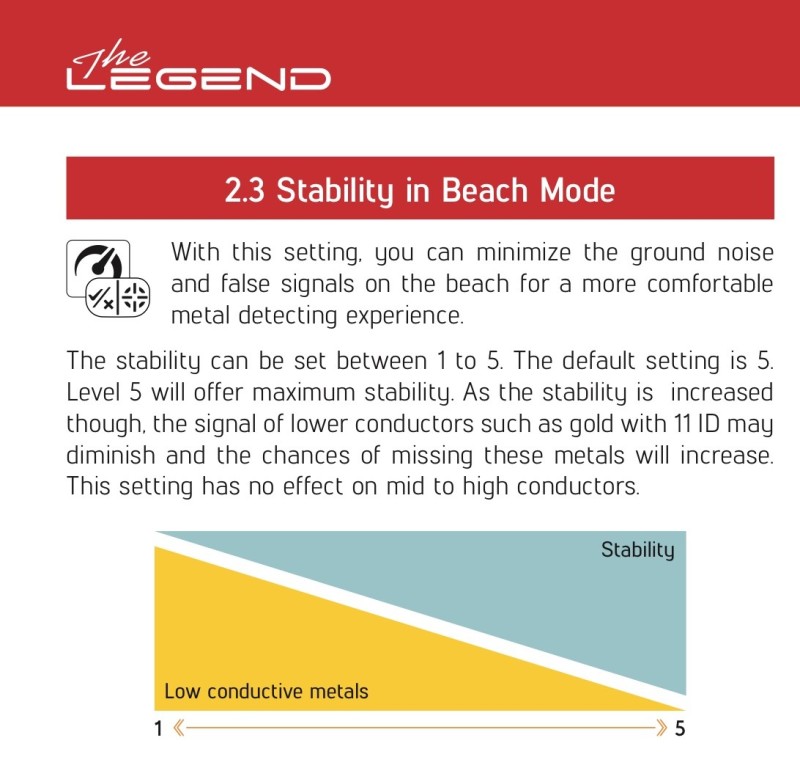

Don’t get me started on the Legend manual! One of my pet peeves about the machine is the manual’s “fuzzy” treatment for many settings. I come to the Legend after 5 years using and fully understanding my Equinox 800 settings, so I had no problem filling in the glaring gaps in the Legend manual with my existing knowledge. I often wonder just how confused I would be if I were a new detectorist just starting out and reading the Legend manual. That said, all we are told about the actual function of Stability for Iron Filter on the Legend is this: Not a lot to go on, but I’ll assume that stability (for Park, Field, and Gold modes only) is just that - a fine adjustment of iron filter for those users who feel they need a little extra tweaking on a given Iron Filter setting. If you’ve ever used a good, old school scientific microscope, the instrument has two focusing knobs - a coarse adjustment and fine adjustment. The coarse focus would get you in the ballpark, but the fine adjustment would really allow you to bring an object into the sharpest focus. That’s how I think about Stability on the Legend. For example, I’m assuming that IF 3, Stab 1 is a slightly higher iron bias setting than IF 2, Stab 5, which in turn is a slightly higher iron bias than IF 2, Stab 3. I’m guessing Nokta decided to provide Stability as a separate setting to IF, because for most folks, the 10 IF settings available in each of the Park, Field, and Gold modes is sufficient for most hunters. Combined with adjustments available at IF 0-7, adding Stability essentially means there are 42 potential Iron Filter settings, which might seem overwhelming to most users if IF ranged from 0-41. Anyway, to answer the actual question…no, I don’t really actively change the Stability setting. I generally set IF at 2. When I first started using the machine in January, I left stability at the default 3. For the last few weeks, I’ve moved stability to 2 just for kicks and giggles, but I haven’t noticed a real difference. But the theory would be, if you’re noticing more iron falsing than you’d like, you can bump the stability up a number or two as opposed to going up a full IF number to address the issue…using a scalpel as opposed to a butcher’s cleaver, so to speak. For me, the question about stability extends into Beach mode. The manual specifically warns that Stability in Beach mode is not the same thing, and then gives a functional description that leaves me scratching my head a little: I’m not sure how that description of Beach mode’s Stability describes something different. If Stability in the other modes is “just” a way to fine tune Iron Filter, and I can use Iron Filter to help minimize false signals and, by extension, some ground noise…I don’t see or understand a difference here. -

I didn’t at the time, but the battery actually came with decent written instructions, if I remember right. This recent thread my El Nino77 shares an excellent step-by-step video: https://www.detectorprospector.com/topic/25212-how-to-change-over-a-minelab-equinox-800-metal-detector-battery/ It’s a very easy process, but it’s extremely important to position your thumb over the battery compartment to avoid damaging the wire harness (see my post in that thread). It’s done that way in the video, but the guy doing the replacement doesn’t specifically point it out.

-

I had the issue that mn90403 described happen just once a couple years ago on my 800. Replaced the battery, and it never happened again. Could be coincidence, but if it happens again, it’s an easy remedy to try. If your battery is 3 or more years old, it probably wouldn’t hurt either way.

-

Replacement Batteries For The 800/600?

AirmetTango replied to Muddydogz's topic in Minelab Equinox Forum

I don’t know if it’s “the best” place compared to any other dealer, but Serious Detecting based in Ypsilanti, MI sells them - they are a reputable dealer selling genuine equipment, unlike the crapshoot you might encounter on eBay. Anyway, they are the folks I bought my battery from when I replaced one in 2022. I received a genuine, OEM battery: https://seriousdetecting.com/products/minelab-equinox-metal-detector-replacement-battery-li-ion-3-7v-100wh-5000mah Colonial metal detectors in New England carries replacements as well - I’ve purchased other items from them in the past and they seem to be a good dealer: https://www.colonialmetaldetectors.com/minelab-equinox-replacement-rechargeable-battery.html -

Carbon Fiber Mid-shaft - Slight Wobble?

AirmetTango replied to glacialgold's topic in Nokta / Makro Legend Forum

Don’t know if will make a difference for you, but rather than wind the tape all the way around, I just put the tape along the bottom of the shaft segment (see pic). Snugs things up, but I can still collapse and extend the shaft without destroying the tape. The tape in the pic has survived multiple hunts, although you can definitely see it’s worn. In my case, I’m not removing the shaft beyond the tape at all so far…the wear will surely increase when I’m switching regularly to the LG24 since I’ll be swapping out at the middle/upper segment. I’m hoping I won’t need to replace it more than monthly. I have it labeled the way I do because if I extend out any further and any tape is showing, the wobble returns even with the tape applied. It isn’t really visible in the picture, but the little white score line that the shaft segment comes with from the factory (I assume it’s the intended extension limit?) is under the tape, intersecting the “E” in extension and the “H” in head. So I have 1” less extension than the “factory” limit when using tape…no biggie, I guess - that’s why I’m using the longer shaft. Silly that we have to resort to using tape on a $500 detector to get it to behave like it should out of the factory. Deja vu with the Equinox original shaft! 🙄 But as you said, first world problems… -

Carbon Fiber Mid-shaft - Slight Wobble?

AirmetTango replied to glacialgold's topic in Nokta / Makro Legend Forum

Adjustable cam locks would be a huge improvement, in my opinion - that’s a great suggestion, Mark. Like I mentioned in my post above, without my painter’s tape addition, I can move the shafts with some pressure even with the locks fully engaged. Adjustable locks would definitely help. I guess it’s not a big deal in terms of day-to-day operation, but it does make me worry how the locks will hold up over the long term with natural wear and tear, especially as dirt or mud gets into the shafts. Looking inside the shafts at how the cam lock functions, you can see there is a small rubber bushing that gets clamped against the side of the cf shaft to provide the friction needed to hold it in place. As that bushing wears, the “loose” friction will only get looser. It would be nice to have an adjustable lock to help compensate for inevitable wear. Maybe not as big of a deal for the cam lock on the middle segment, because you can easily just replace the segment (although annoying to have to put out the extra cash to compensate for a weakness in design). The upper cam lock is a different story though - since it’s fully integrated into the handle and control box, I don’t see how it gets replaced independent of the whole shebang. In the meantime, you better believe I’ll be spending time after most hunts disassembling the shaft and making sure those cam locks and bushings are clean. -

Carbon Fiber Mid-shaft - Slight Wobble?

AirmetTango replied to glacialgold's topic in Nokta / Makro Legend Forum

Yes, I’ve noticed this issue as well - on two Legends. To make a long story short, my dealer accidentally sent me a used Legend when I purchased mine earlier this year, and both that one (which got sent back) and my brand new one exhibit the wobble and flex. I can also move the shaft segments with the locks fully engaged with a little effort (on both machines). I’m 6 foot even also, and prefer a longer shaft for a wider than average swing arc. Extending the stock shaft segments to the length I wanted just doesn’t seem to leave enough overlap in the segments and definitely makes matters far worse while the LG30 is attached. Like you, I experimented with leaving extra length of each shaft inside its mate, and for me, it helped - the lower shaft flex and wobble improved to where it’s almost imperceptible, but at the upper/middle shaft junction with extra overlap, it didn’t eliminate the issue enough…there’s still noticeable shift. It isn’t awful, but it is distracting coming from a machine with a two piece, but solid performing, shaft. And of course, with the extra overlap, I can’t quite get the overall shaft extension that I want. So, like you, I bought the longer shaft segments, both lower and upper for use with the LG30. To eliminate the remaining shift, my “long term” solution is a small piece of blue painter’s tape on the bottom side of each shaft segment. This not only eliminates the remaining slop, but also snugs up the fit enough that I can’t move the shafts when they are in the locked position without considerable effort. The wobble/flex situation doesn’t seem to present itself when I attach the LG24 with the original shafts on my machine. So I use the original shafts with the LG24, and the “tall” shaft segments with the LG30. The downside with the tall shafts is that the machine isn’t quite as compact when collapsed down. Edited: I kept saying the LG28 coil when I meant to be saying the newer LG30 coil. Fixed it! -

I replaced the battery on my Equinox 800 about 1.5 years ago, and the process is quite easy to do, just as the video shows. One caveat - take his warnings (1:07 mark) about taking your time and being gentle very seriously. Notice at the 1:30 mark how suddenly the battery releases - if you aren’t careful, that release can stress and damage the wire connections further up in the housing (not the white connector - that’ll be fine. I mean the control box wires inside the housing). Keep in mind, the older battery you are replacing may have changed shape - in my case, I believe the battery may have swelled ever so slightly over time, making it more difficult to remove. I needed to exert a surprising amount of force, and the battery released very suddenly - with greater speed than you see in the above video. He doesn’t point this out, but notice that he positions the thumb of his hand grasping the control box directly over the battery to serve as a “barrier” for when the battery releases. This is critically important to avoid potential damage! Again, the process is easy, and only takes a few minutes, but done the wrong way, it very much can cause damage

.thumb.png.7964a006255f392e5c7f907ff0d7c2ca.png)