-

Posts

19,845 -

Joined

-

Days Won

4

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by Steve Herschbach

-

Glenn has a LiPo setup I believe, but he must be out prospecting. I will see if I can get his attention. I always just used the Minelab battery myself as does everyone I have met in the field except for Glenn. Best rechargeable battery I have ever owned and minimal risk using it. I am selling my backups in the Classifieds now that my GPX is for sale. Here is a thread on the pinout http://www.nuggetshooter.ipbhost.com/index.php?showtopic=20092

-

This should be interesting. The reality these days is that when it comes to nugget detecting I am very much a pulse induction kind of guy. I also go out of my way to point out the problems with using VLF detectors and discrimination while nugget detecting. Yet at the same time I have very much been a proponent of using VLF detectors and discrimination where it may offer some sort of advantage. Ganes Creek, Alaska was the best example of a location with large nuggets and tons of ferrous junk to contend with. A good discriminating VLF detector made sense there and the vast majority of the gold found at Ganes Creek was found with VLF detectors. I am seeing similar situations here down south, especially in California. Places where 150 years of mining has left ferrous trash galore. What I am looking for is a way to narrow things down a bit in some situations. The idea in some places with unknown potential is to scout first with the VLF, and then, if any gold is found, to switch to a PI and hammer the spot. There are the big cobble piles, that may have a big cobble shot full of gold, but which are more likely to contain a rusted can. A big coil on a VLF could be handy for scouting those. Finally, I want to do some honest blue sky prospecting where I put myself in gold country but not specifically on a proven location and go looking for a patch. A lot of this would be in logging country and steel wire and other ferrous trash can be common. I can deal with the bullets but may want to weed out the ferrous. I ended up by chance with a Nokta FORS Gold that came with a 13.5" x 15.5" DD coil. This machine has a great two tone mode where all targets signal, but ferrous with a low tone, and non-ferrous with a high tone. My preferred mode for scouting trashy terrain. I hear all targets so nothing gets passed without thought. I may investigate some ferrous signals further if I am suspicious. I have a new Fisher F75SE coming, a model without the latest updates. I may end up also with an updated version but got tired of waiting on that so bought this one to use for now. It also gives me a baseline to compare to should I ever lay hands on a newer unit. Or one I can upgrade later if I wish. To compare apples and apples I have a new DeTech 12" x 15" DD coil on the way for the F75 to use versus the Nokta with similar coil. I have a friend who did very well at Ganes Creek in the 22.5 kHz dedicated frequency prospecting mode, and his main claim was that it had killer discrimination. So just to make life interesting I have another DeTech 12" x 15" DD coil on the way to use on the V3i versus the other two detectors. Finally, I will toss my CTX 3030 with 13" x 17" coil in on this little competition though it is a slightly different coil. Close enough though and should be interesting. There is already a huge thread going on the CTX and gold at http://www.detectorprospector.com/forum/topic/361-minelab-ctx-3030-for-gold-nuggets/ I honestly look at this as more a shootout between the F75 and the Nokta more because I see them more as get down and play in the mud prospecting detectors. The CTX and V3i are more my in town units. But maybe that is just a perception thing on my part and since I own both anyway - why not? Looked at another way these do represent some company flagship units, say what else you may about them. Maybe there will be surprises and no matter what, I have a lot to learn here. And that, my friends, I do enjoy! OK, now the bad news. I am not much for contrived testing so I will need favorable weather to get these detectors out of town into real field conditions to give this all a try. And I do not want to rush to judgement in any case. Eventually it will all sort out and I will report along the way if anything of interest develops. Until then, you will have to be patient. Again, lest anyone think I am believing this all to be some kind of magic gold getting idea, it is not at all. I will be using a PI detector for most of my nugget detecting in 2015 and basically digging everything I come across. This is actually part of my weeding down detectors process with the main goal being to let either the F75 or FORS Gold go away. I have other reasons for keeping the CTX and V3i so they are just going along for the ride and the potential for extra knowledge. When I go out this summer I want to be packing both a PI and a VLF. The intent is to use the PI and have the VLF more for backup or for getting into a real trashy location. This shootout will determine just what VLF gets to go with me this summer. The photo below shows all four coils side by side with weights as weighed on my postal scale with scuff covers. The dimensions are width by length at longest point with the third dimension being the length of the actual middle DD overlap working area. The two DeTech coils are 12.75" in this regard versus 14.25" for the Nokta and 15.5" for the CTX 3030. This would be the nominal length to shoot for on each coil sweep if you figure no overlap (which would not be wise). The Nokta is the lightest coil so in theory combining weight with area covered it has the best overall specs as regards area covered for weight handled. The angle of the picture and coil placing tends to make the Nokta coil look smaller than the DeTech coils but it is in fact slightly larger. Last funny note. I would normally complain about putting coils this size on VLF detectors because in the past it made them nose heavy and had me whining about the weight. However, world class lead weight PI detectors have made it so I have gotten used to using machines far heavier than these beasts, even with their larger coils. Go figure.

- 5 replies

-

- dfx vx3 v3i

- minelab ctx 3030

-

(and 1 more)

Tagged with:

-

Specialized Small Diameter Probe

Steve Herschbach replied to wirelessguy's topic in Metal Detector Advice & Comparisons

The Falcon lacks the basic requirement here - the ability to discriminate. Also, it really is just a pinpointer so no sideways looking capability and very poor depth. -

Specialized Small Diameter Probe

Steve Herschbach replied to wirelessguy's topic in Metal Detector Advice & Comparisons

Well, you found the Geotech website, and that is THE place for this question! Will this idea work in general? - I think so. Is one of the figure 8 configs the right topology? - Not necessarily. Could go DD or even concentric. Concentric generally give superior ferrous/non-ferrous indications. DD better handles ground mineralization, and figure 8 adds superb EMI resistance. Any other hints on making this probe before I start? - yeah, get back to Geotech! What distance from centerline of 2” dia drilled hole can I expect to discriminate on a US nickel sized object for ferrous/non-ferrous? - A few inches at best. Problem is two inch hole with shell needed around coil. Take best case, a Hot Foot coil for MXT is 2" (actually a hair over that probably) by 9" long, DD configuration. Make a bit skinnier with cable out rear, bingo, you are done. I own Big Foot by same company, 3" x 18" figure 8, obviously could be made same size as Hot Foot. A Sun Ray probe for MXT could easily run down the hole but minimal ability to look to side unfortunately. The thing is coil depth is tied to the width of a coil, not the length. You will have what, maybe a 1-3/4" wide coil? Not going to get much reach. One thing to look into is effect of extra long cable. You will have to compensate for that past a certain point. Old page with Hot Foot and Big Foot info. Guy that made them passed away and they are highly sought after, sell for twice or more what they did new - because they are hard to make! But obviously it can be done. http://www.whiteselectronics.net/calif/accessories_loops_.htm -

I got tired of trying to find a piece of aluminum I needed to build my custom ATX metal detector http://www.detectorprospector.com/forum/topic/462-garrett-atx-strip-down-rebuild/ and finally just found it online. I do not know if these guys are a good deal price-wise but they have a heck of a selection and great online process. Check it out at https://www.metalsdepot.com/ You have a great metals supplier, please post them here.

-

Hi gambler, The goal of the thread is not to try and talk you into digging everything. It simply is information about how VLF metal detectors work so you can make informed choices. Yes, you could use a bottom of the line detector and dig everything but the depth will be far less than that had by a good ground balancing prospecting detector. Most inexpensive models have a factory preset ground balance which means they have poor performance in most goldfields. If the thread got somebody who is using discrimination habitually to just scrape a little soil off the top of weak signals it will mean somebody will find a nugget they might have missed. Then it will have served its purpose.

-

GPX Coil Question - Mono or DD?

Steve Herschbach replied to hawkeye's topic in Minelab Metal Detectors

My advice - get a mono. One of the main advantages of the GPX is the ability to leverage mono coils for maximum effect. My DD coil for my GPX never got used at all. Hardly anyone uses DD coils on a GPX unless they are wanting to use the discrimination system. The big question is which mono to get, and that is one question everyone has a different opinion on. Chasing smaller stuff, get the Sadie coil or 8" Commander. For a little larger coil the 12" x 15" Commander mono is a good coil. Or the 11" Commander the 5000 comes with, one of the best and least respected coils around. -

How Small Is Your Smallest Piece Of SDC 2300 Gold?

Steve Herschbach replied to rumblefish's topic in Minelab Metal Detectors

Mine is the bottom of a Wearever stainless steel pan. I have been experimenting with backgrounds for gold photos. Steel backgrounds seem to work very well in conjunction with digital cameras to produce natural gold colors, especially in sunlight. The other good result I am getting is with flash and gold held in the air with a dark background. -

In two locations in California I have been on very, very hot ground with the SDC 2300. Extremely red and loaded with magnetite. The SDC struggled with it, kind of groaning as the ground balance tried to keep up. I would get a faint signal I would think was a possible nugget, and scratch into the stuff. It would go all kinds of "sparky" for lack of a better term. After messing with it I decided these were basically patches of almost pure magnetite. Soil sitting in place does actually end up with the particles being magnetically aligned and stirring it up is kind of like stirring up a hornets nest. Luckily these places are more like small patches and so not something I had to deal with overall. From Bruce Candy at https://www.minelab.com/__files/f/11043/METAL%20DETECTOR%20BASICS%20AND%20THEORY.pdf "Thus, USA goldfields are typically different from Australian goldfields: • The USA soils are mostly mildly mineralised but in some areas may contain either nearly pure magnetite black sands or rocks, which are problematic for metal detectors as they have very high X components (strongly attracted to magnets). • Australian gold fields have highly mineralised soils, but very few black sands or rocks that contain nearly pure X magnetite. The magnetic materials are in the forms of magnetite-rich small pebbles and rock coatings, clays and general “sandy” soils. These all contain magnetic materials that produce high levels of X signals as well as R. The ratio of X and R is random, and the R component arises from extremely small magnetic particles called superparamagnetic materials..." Predicting Soil Influence on the Performance of Metal Detectors: Magnetic Properties of Tropical Soils http://www.jmu.edu/cisr/journal/13.1/rd/igel/igel.shtml Influence of Soil Properties on the Performance of Metal Detectors and GPR http://www.jmu.edu/cisr/journal/17.1/RD/takahashi.shtml

-

And the great thing is now you can get out the water hose and spray the mud off your detector. Nice to have a machine for wet muddy conditions. You guys sure have sticky mud down here. In Alaska it is loose and just hoses off. The stuff sticking under my truck here I almost need to chisel off!

-

Lets Talk Warranty

Steve Herschbach replied to gambler's topic in Metal Detector Advice & Comparisons

I agree with Harry that this problem is more prevalent in recent years. It was not long ago that most detectors were pretty much hand made one at a time and each had to be individually tuned prior to departure. The tuning process WAS the quality check as the person tuning it up knew if something was wrong. Now you get parts and components simply put together and shipped. Mass production demands the end of the hand built through hole circuit board process in favor of a machine assembled surface mount circuit board. There is another big elephant in the room also. The Internet. One of those older companies could ship out ten bad detectors to ten places around the country and basically you just never heard about it. Each customer would be told they were the only one having the problem. The Internet not only allows people to catch things collectively much quicker but to magnify the impact since complainers are far more vocal than happy people. -

Like I said, go by tones if you want. The detector decides it is ferrous, gives you a ferrous tone. Same difference. In other words, the detector determines the target id number first, then displays it visually as numbers or audibly as tones. If the underlying decision is wrong, the number or the tone will be wrong. I agree hunting by tones is better as you get fleeting audio indications and nuances that say a hundred times more than any number can. Digital read outs as worthless hype? Everyone is entitled to their opinion on that and what works for them. They are not worthless for me. Not everyone has great hearing and many people are tone deaf. I love the displays on my V3i and CTX 3030. Whether they make me hunt any better is debatable. My personal preference in VLF detectors is to have it available in addition to tones to use as I see fit as opposed to not having it at all. Note the key there - personal preference. I like hunting in multi tone modes as it paints a tonal picture of targets as opposed to dual tones, which gives a binary high low way of hearing things. Visual displays are the same, in that simple systems just put a number on screen. The V3i or CTX paint pictures on screen that display signal intensity and cumulative effect of hundreds of VDI samples. In the case of the V3i you get a picture of the same item in three frequencies. All this can be used by experienced hunters to get very good at deciding what to dig or not dig in urban trashy parks. Frankly, it is also kind of fun to play with. But is it better? Those very rare times I am just trying to dig silver coins, yes, it is. But much of my detecting boils down to just digging all non-ferrous, and so those systems are overkill. I still enjoy them though. The entire point of this article however is that even just digging all non-ferrous can get problematic. Here is a great video that illustrates how even listening to tones is a problem in really bad ground. I read all the time about people digging coins back east at 8" or 9" or 10" plus. Yet everywhere I go it seems 5" - 6" is about it for accurate discrimination with the best machines. Here we have a video comparing four top notch machines - the Teknetics T2 (pretty much same as Fisher F75), Garrett AT Pro, Minelab CTX 3030, and XP DEUS. Now the goal here for me is not to show any machine is better than another. Just focus on what is going on with a large non-ferrous item buried about 5" deep in hot red soil. The machines struggle to identify it as non-ferrous just going by tone. Target id numbers are all over the map. Then toss just a single nail on the surface, and it gets even worse. I am not a big fan of comparison videos in most cases because they are so easily manipulated but this one clearly shows how bad ground and discrimination can really cause good items to be missed, and why ultimately using a VLF in all metal or a PI and digging it all is the only way to get it all.

-

Lets Talk Warranty

Steve Herschbach replied to gambler's topic in Metal Detector Advice & Comparisons

Well, I am not a tech, but it goes like this. Electronic components vary within an acceptable range, plus and minus. How much depends on how much the manufacturer spends to source the components. In theory the pluses and minuses average out, but sometimes you get a cascade effect where everything goes plus or everything goes minus, and you get a detector performing out of specification. Coils are the real biggie. There is a huge variance in coils as manufactured and many just get tossed in the dust bin. This goes along with the fact that there are detectors that are tuned as a set with the coil they come with. If the owner changes the coil it may now be out of spec to a greater or larger degree. These things were more common in analog models and in theory should be less common with modern manufacturing processes. Yet on-going events at Fisher as I type see people reporting widely varying results with recent machine upgrades and purchases. So it is an issue to this day. The key to everything should be quality control. Every detector should be tested to within spec before it goes out the door. The question is, how wide is the acceptable variance? And how good is the final check process? The fact that I could buy detectors that were dead on arrival means some get past somehow. I have no idea how the process actually works and how it differs at the companies. It may be like everything else though - dollars get short, and the first guy laid off is the quality control guy. The ones that you never hear about and nobody thinks about though are the ones that get out the door and basically work. But are an inch or two short in depth. How many online detector wars are the result of two people getting two different versions of the same detector, one that works well and one that does not. If you have nothing to compare to the assumption will be that is just the way they all are. Given that most people who buy detectors have no idea how they should work, and that huge numbers get little or no use - well, you tell me, what is the reality with that whole can of worms? This I and virtually everyone that has been around knows for sure. There are really hot units and some real duds, and the vast majority are somewhere in the middle. -

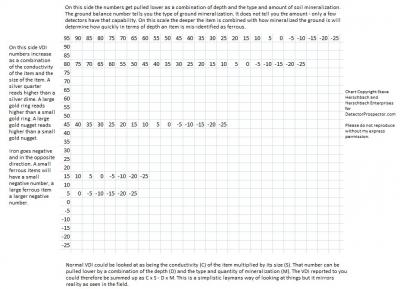

Final summary - the higher the magnetic susceptibility of the soil, the less accurate VDI numbers are and the lower they will tend to be pulled with depth. For coin hunters that means an item reading as a pull tab may be a silver coin. And for nugget hunters, that ferrous reading may very well be a gold nugget.

-

OK, this is an attempt to visually quantify all this. It may of may not succeed in helping everyone but I had to give it a try. This chart I concocted shows increasing VDI numbers on the left, and how they can get pulled lower to the right by a combination of depth and ground mineralization. The effect is not strictly linear. It depends on the detector and type of ground balance and discrimination system employed. The Minelab BBS and FBS units employ a method that tends to keep the VDI number as accurate as possible as deep as possible. They therefore enjoy a reputation for very accurate target identification. Unfortunately, they have lackluster depth in highly mineralized ground. That is not their fault - they are just eking out accurate target id as deep as it can be had, and in mineralized ground that is not very deep. In other detectors the effect is rather linear - the deeper you bury the item, the lower the VDI number. It is a common misperception that the ground balance setting on a metal detector tells you how bad the ground is. It is only vaguely related to that. The ground balance setting is determined by the type of ground mineralization you are dealing with, but it does not directly report the amount of ground mineralization. In other words, you may be setting the ground balance to reject magnetite, the most common iron mineral in a lot of locations. What you do not know is whether you are tuning out a lot of magnetite or a little magnetite. Several Dave Johnson detectors like the White's GMT and the Fisher F75 and Gold Bug Pro plus Teknetics T2 have Fe3O4 amount readings to complement the ground balance reading. It is this combination of the TYPE of ground mineral as indicated by the ground balance number and the AMOUNT of ground mineral as indicated by the Fe3O4 meter. From the Gold Bug Pro manual: Understanding ground conditions assists the user in setting up the machine, knowing when to readjust ground balance, and in understanding the responses of the machine while searching. This detector displays two kinds of ground data: 1. The type of mineralization (which affects where the ground phase should be set). This is GND PHASE 2. The amount of mineralization (the greater the amount of mineralization, the greater the loss of detection depth & ID accuracy; this loss is more pronounced in Discrimination Mode). This is Fe3O4. The goal of ground balancing is to equate the GND BAL number to the PHASE number. PHASE is the measurement of the ground. GND BAL is the detector’s internal setting which calibrates the detector to the ground’s phase. Notice that the GND BAL number is three digits, with a decimal point. PHASE has only two digits. GND BAL is a higher resolution number, so may differ a bit from PHASE in a perfectly balanced scenario. After pumping and releasing GG, the exact measurement of the ground will be transferred to the GND BAL setting. The two-digit PHASE number displayed on the screen indicates the type of ground mineralization. Some typical ground mineralization types are: 0 – 10 Wet salt and alkali 5 – 25 Metallic iron. Very few soils in this range. You are probably over metal. 26–39 Very few soils in this range -- occasionally some saltwater beaches 40–75 Red, yellow and brown iron-bearing clay minerals 75–95 Magnetite and other black iron minerals Fe3O4 BARGRAPH The Fe3O4 7-segment bargraph indicates the amount of ground mineralization, independent of type, expressed as an equivalent volume concentration of magnetite (Fe3O4). It updates every second. It is sensitive to motion and will give the most accurate readings if you pump the searchcoil up and down several times over the ground. The presence of metal or “hot rocks” will cause the readings to be inaccurate. If you stop moving the searchcoil, the bargraph will go blank. INDICATION RELATIVE % Fe3O4 SUSCEPTIBILITY MINERALIZATION 7 Bars -------- High over 1 over 2500 2 to 6 Bars -- Medium .026 - 1.0 61 - 2,500 1 Bar --------- Very Low 0.006 - .025 15 - 60 none -- less than .006 less than 15 Magnetic susceptibility is expressed in micro-cgs units. In a salt water environment in the absence of iron minerals, the bargraph indicates relative electrical conductivity. In soils with greater than 10,000 micro-cgs units magnetic susceptibility, the signal from the soil may saturate, or overload, the circuitry. This will not harm the detector but the machine will not be usable in that condition. The solution is to hold the searchcoil several inches above the soil surface so it is not “seeing as much dirt.” By listening and watching you will know how high you need to hold the searchcoil in order to avoid overload. The highest magnetic susceptibilities are usually found in soils developed over igneous rocks, in alluvial black sand streaks on beaches, and in red clay soils of humid climates. The lowest magnetic susceptibilities are usually found in white beach sands of tropical and subtropical regions, and soils developed over limestone. The Fisher F75 and Teknetics T2 have a better defined Fe3O4 meter as explained in the T2 manual: BAR GRAPHS Fe3O4 (magnetite) This bar graph displays the magnetic mineralization factor, or magnetic susceptibility, of the soil. Magnetic susceptibility is expressed in terms of the percent volume of the iron mineral magnetite, which most black sand is made of. The depth to which objects can be accurately identified is strongly influenced by the magnetic susceptibility of the soil. High Fe3O4 values have a greater effect on detection depth in the Discrimination mode than in the All Metal mode. For the most accurate Fe3O4 reading, pump the searchcoil as though you were ground canceling. Fe3O4 approx. Range micro-cgs Description 3 --- 7,500 --- uncommon but not rare, heavy mineralization 1 --- 2,500 --- heavy mineralization, not uncommon in goldfields 0.3 --- 750 --- heavy mineralization, but not uncommon in some regions 0.1 --- 250 --- medium mineralization, typical 0.03 --- 75 --- light mineralization, but common 0.01 --- 25 --- light mineralization, often low G.C. setting blank <14 --- quartz & coral white beach sands From Bruce Candy at https://www.minelab.com/__files/f/11043/METAL%20DETECTOR%20BASICS%20AND%20THEORY.pdf "Thus, USA goldfields are typically different from Australian goldfields: • The USA soils are mostly mildly mineralised but in some areas may contain either nearly pure magnetite black sands or rocks, which are problematic for metal detectors as they have very high X components (strongly attracted to magnets). • Australian gold fields have highly mineralised soils, but very few black sands or rocks that contain nearly pure X magnetite. The magnetic materials are in the forms of magnetite-rich small pebbles and rock coatings, clays and general “sandy” soils. These all contain magnetic materials that produce high levels of X signals as well as R. The ratio of X and R is random, and the R component arises from extremely small magnetic particles called superparamagnetic materials..." Predicting Soil Influence on the Performance of Metal Detectors: Magnetic Properties of Tropical Soils http://www.jmu.edu/cisr/journal/13.1/rd/igel/igel.shtml Influence of Soil Properties on the Performance of Metal Detectors and GPR http://www.jmu.edu/cisr/journal/17.1/RD/takahashi.shtml

-

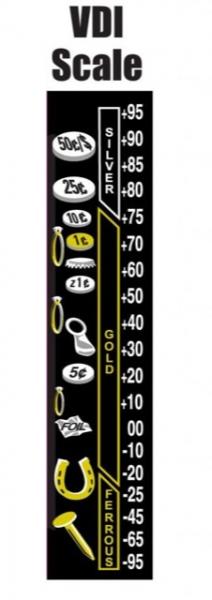

Thanks Bob, One thing bears repeating. Here is the same chart as presented by Garrett. Their VDI scale is similar to White's. I added the vertical yellow lines for emphasis. Ferrous/non-ferrous overlap region All the scales and charts will say the same thing. They tell you small gold and iron readings overlap. This is not actually true except in air testing scenarios in that it is even worse in the ground. Almost all non-ferrous targets can read ferrous in mineralized ground regardless of size. It is not about the item being small, it is all about the signal being small or weak. So bury that two ounce nugget a few inches deep, you get a big signal, like a big gold nugget. But bury it really deep, and now you have a signal just like that small gold nugget. And just like that small gold nugget, it can read ferrous. The ground signal is overwhelming the gold signal. I want to make sure people get this because the manufacturers with their charts and scales all tend to imply this is only an issue with small gold items. It is an issue for ALL items, and not just gold. A silver half dollar will read ferrous if you bury it deep enough in bad ground. The obvious solution is to use VLF all metal and dig everything, or better yet a pulse induction and dig everything. When nugget hunting this is recommended practice. Unfortunately for most coin detecting in areas occupied by humans it is not practical for many reasons, and even for nugget detecting in some locations the amount of trash will try the patience and backs of the most die hard individuals. There is a place for VLF discrimination, but again, only as long as one is aware of the limitations. My best advice is to go more by site selection than anything. Use a VLF to deal with trash overall, but if you find good items in any area, shift to dig-it-all mentality. Any location that has good items worth digging is generally worth digging all items!

-

Lets Talk Warranty

Steve Herschbach replied to gambler's topic in Metal Detector Advice & Comparisons

I owned one of the largest detector shops in the US starting in 1976 that in latter years was selling around 500 detectors a year. I have also owned a large number of detectors over the years. Roughly one or two a year at the dealership were found to be defective when sold. The cause in most of those cases was a bad coil. Coils fail far more often than control boxes. Of new detectors, waterproof detectors are more prone to warranty issues than other models. Some detectors we sold may have had issues at a later date not reported to us but I would think a failure rate of new detectors under warranty of under 1% is reasonable from what I experienced. You may think it is more from what you see on the internet sometimes, but happy people never post. All you hear from are people with problems, and in very many cases those problems turn out not to be real. Number one cause for detectors to come back to dealers of get sent to factory? Batteries dead or in backwards. As well built electronic items, if a detector is good for a year, it often is good forever. I am being perfectly honest with you in saying that when I buy used detectors, and I do, I really do not worry about warranty at all and have no problem buying detectors ten or more years old. If they work - they work. Waterproof is where the concerns are. I have only personally sent back three detectors ever for warranty work, and two of those were waterproof detectors. One was a White's Surf PI on my first real underwater detecting expedition to Hawaii. Leaked like a sieve brand new! Kind of ruined my trip also, and I have never traveled with less than two detectors ever since. White's had problems with those early models and later redesigned the control box. The other was a Tesoro Stingray. I could see water pour into the control box under the clear cover the first time it went underwater. That was after a long hike into a canyon and suiting up in a drysuit so also a ruined trip. Now my new underwater detectors spend a day submerged in the bathtub before I even think of taking them out. The last detector was more recent - last year. It is sctually waterproof also but this problem was unrelated to that. My brand new Minelab CTX 3030 went for over a year before I even bothered to try the GPS system. When I finally tried it, it would never acquire a satellite. Not a big deal but not as it should be. I contacted Minelab, they paid for return to fix, fixed immediately, and returned postage paid. The units mentioned above were also serviced immediately. Not quite personal purchase but almost. I purchased four Garrett Infiniums for use by our customers at Moore Creek Mine. All four of those units had either control box or coil issues with use that required return for repairs. Rather surprising as the unit looks to be built like a tank. So there are some more waterproof detectors with issues. The ones I saw in store as I said were usually coil issues and usually spread around by manufacturer. Nothing you can pin down real hard. My impression is that White's and Tesoro have above average quality control, Minelab average, and First Texas (Bounty Hunter, Fisher, Teknetics) and Garrett maybe below average. First Texas in particular seems to have problems with every new model introduction as of late. The real issue out there is that many detectors work but may be substandard in performance and many owners may not even be aware of it. All the manufacturers have excellent service and support. Minelab went through a period some time ago where it was horrible, basically non-existent. But they are well past that now and top notch from what I and others have experienced recently. I would have to pick White's out as the company that stands out for service. They will repair 40 year old models if they can get the parts. So bottom line just my experience and opinion, I am very confident buying used detectors that are out of warranty with the exception of waterproof models. Those I prefer to buy new with warranty. -

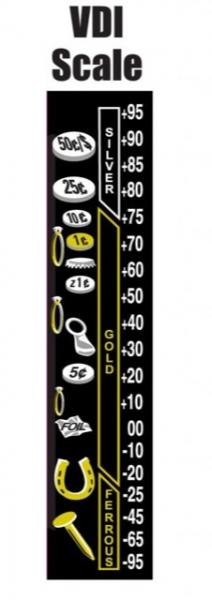

VLF metal detector discrimination works well on isolated targets in an air test. The problem is in the field what is reported by the detector is the sum of everything the coil "sees". This means the ground mineralization, the gold nugget (or any other item you are trying to find), other metal under the coil at the same time, and even electrical interference. Sweep speed matters also as does the angle of the item in the ground and the direction from which the coil approaches it. Add it all up, and it is a miracle discrimination works at all, and the reality is it is wrong very often. Almost any ground with iron mineralization will cause non-ferrous items to read as ferrous. Usually it is something that happens right on the edge of detection depth. However, the more iron mineralization, the less depth it takes for the item to flip over to ferrous. It does not matter how large the item is either. Small non-ferrous items are more prone to reading ferrous but even very large items will flip in very bad ground. Bury a two ounce nugget deep enough in bad ground, and it will read ferrous. The ground mineralization pulls the VDI numbers down, and the deeper the item is buried, the lower the VDI number gets until it passes into the ferrous range. This happens with coins when coin detecting. A person using discrimination is looking for items that read in a certain number range. The problem is that mineralization pulls those numbers lower and then the items reads instead as a trash item, and is left behind. The simplified explanation is the detector is seeing a little bit of non-ferrous signal and a lot of ferrous ground signal. The White's GMT is a rare machine that tries to show you this graphically. It will say a target has a 40% chance of being non-ferrous. Most machines have to call it one way or the other and in this example just go ahead and call it ferrous. Which is it? Ferrous? Or 60% chance of being ferrous? Would you dig something if you knew it had a 40% chance of being a nugget? A picture says it all. See the one below. This is such a well known thing that White's has for a long time shown it on their simplified VDI (Visual Discrimination Indicator) scale. On most White's 1 through 95 indicates non-ferrous, and the negative numbers -1 through -95 indicate ferrous numbers. Notice how ferrous readings as low as -20 could indicate gold. Yet nearly everyone using any discrimination at all will tune out this range to eliminate finding small ferrous trash. This happens on all VLF metal detectors that employ discrimination. Good old Ganes Creek, Alaska is a VLF test bed on a massive scale. Tons of ferrous trash is buried intermingled with gold nuggets in tailing piles. The ground is not all that mineralized and VLF detectors work well there. Because the hunting was pay-to-mine competition style a VLF made more sense than digging hundreds of ferrous targets with a PI while your buddy was cherry picking nuggets around you with a VLF. The reputation of the White's MXT as a nugget finder was largely built at Ganes Creek, but many other VLF detectors did well. I saw a couple things over and over at Ganes Creek. First, we ran detectors in either of two modes. Dual tones with low tone ferrous, high tone non-ferrous was the most popular. Or there were some who ran in all metal mode then analyzed the target VDI once located. I did both. In either case you could get two results very often. In my case running a F75 in all metal I would get a target. I would then sweep it and watch the meter VDI numbers. What I learned is if there were five sweeps that said ferrous and just one that read non-ferrous, then dig it. Most people are looking for reasons not to dig. Getting five readings ferrous and one non-ferrous, most people would take that to mean a ferrous target. What I found more often than not is that if I could just get the target to read non-ferrous even once, it was worth digging. These were usually items reading borderline anyway. The only stuff relatively safe to walk away from is items that give strong ferrous readings repeatedly. With dual tones the same thing applies. If you get five low tones but then get it to bounce high tone even once, better dig it. The real proof was the simple kick test. You go along, get a ferrous indication, and kick a couple inches off the surface and bingo! the ferrous item turns non-ferrous. Pretty amazing stuff. Keep in mind folks, this is relatively mild ground! What not to do. If you take any detector and tune it to completely ignore ferrous targets, you are in big trouble. The Gold Bug 2 for instance. If you flip to Iron Disc mode iron targets are ignored as if they are not there. Yes, some will click or pop but most simply get ignored. Any detector with a simple knob, like a Tesoro Lobo in disc mode, you can turn up until a small nail will be ignored. Hunting directly set up to reject ferrous is very problematic. Now you can find gold doing this. I have and many people have. The problem is as you go along you only get one chance at the target. If you hunt in all metal, you will always get the target, and then you can analyze at your leisure, or just dig it up. In dual tone you will always be alerted to the target, so you can check it again. But if you set to reject, and the detector makes a bad call on the first sweep, you pass over the target and never know it was there at all. Part of the problem is in targets that you only get partly over on the first pass. For the discrimination to have its best shot, you need to be centered on the target as much as possible to get the strongest signal. An on edge pass will usually be wrong, but if you are alerted you can make multiple sweeps to get centered on target for the best reading. Any detector running in disc mode will have a search field that is more limited in extant than that you experience with the detector in true all metal mode. In disc mode you need to be well centered. In all metal, the coil reaches wider and deeper to gather signals. The reason I usually run in all metal is it gives me the best chance of capturing the target, then I can decide what to do with it. Running directly in disc gives you more chance of missing the target entirely. Keep in mind these issues vary wildly with the amount and type of iron mineralization in the ground. I saw some ground in Alaska recently that you would not think was very mineralized. No intense red colors, not much in the way of hot rocks. And yet there was something about the iron in the ground that made fairly large nuggets and even .22 shell casings read as ferrous when sitting directly on the ground in plain sight! Very, very scary stuff. Now having said all that, there are times I will crank up the disc and eliminate the signals. Sometimes they are overwhelming in number and it is the only way to deal with it. Maybe I am just tired and not in the mood to analyze every target. Maybe time is very limited and I need to do a quick cherry pick run of the ground. There are no absolutes in metal detecting. The main thing is to have the knowledge required to make the best choices you can, to get the best odds for the situation. Hopefully this little article will help. For more technical detail see Metal Detector Basics and Theory by Bruce Candy / Minelab. An excerpt: “In goldfields, discrimination is required only against ferrous targets, without any time constant discrimination, as gold nugget time constants include all values from very long to short. Unfortunately, X discrimination in goldfields has several major problems: Most productive goldfields are extremely mineralised, and thus the soil X signal is extremely large. As was stated earlier, it is only possible to assess the target X signal if this is comparable to, or greater than, the soil signal after filtering. In such extremely mineralised soil, this will only occur when the target signal is also very large which means the target must be close to the metal detector coil. Hence, discrimination in highly mineralised goldfields is only effective for targets buried at shallow depths. The discriminator action must be very conservative so that gold nuggets are not falsely discriminated as ferrous targets. Thus, the metal target signal must not only be comparable or merely greater than the soil X signal after filtering, but significantly greater so that there is no doubt whether the metal target is ferrous or not. This further reduces the depths at which targets may be discriminated.” Related Threads/Posts: What Is Metal Detector Discrimination? Target ID More About Size, Than Type Of Metal Metal Detector Discrimination Really Sucks Metal Detectors With Reliable Target ID Numbers The Ferrous / Non-Ferrous Overlap European Detectors Versus U.S. Style Detectors On Target Masking Metal Detectors With Reliable Target ID Numbers

-

You are welcome! This whole issue of non-ferrous items reading as ferrous in highly mineralized ground is so important I wanted to restate it again, but simplified this time. Almost any ground with iron mineralization will cause non-ferrous items to read as ferrous. Usually it is something that happens right on the edge of detection depth. However, the more iron mineralization, the less depth it takes for the item to flip over to ferrous. It does not matter how large the item is either. Small non-ferrous items are more prone to reading ferrous but even very large items will flip in very bad ground. A picture says it all. This is such a well known thing that White's has for a long time shown it on their simplified VDI (Visual Discrimination Indicator) scale. On most White's 1 through 95 indicates non-ferrous, and the negative numbers -1 through -95 indicate ferrous numbers. Notice how ferrous readings as low as -20 could indicate gold. Yet nearly everyone using any discrimination at all will tune out this range to eliminate finding small ferrous trash. This happens on all VLF detectors that employ discrimination.

-

The plot thickens. I think we have a situation where a few people are making lots of noise. Not saying it is not justified, but looking around the internet the disparity of reports is interesting. On Dankowskis and Findmall a few disgruntled parties. Everywhere else, happy people. Icing on the cake though is this video just released. I want one of these!

-

Any Info On the New F19

Steve Herschbach replied to WyoBuck's topic in First Texas - Bounty Hunter, Fisher & Teknetics

Good commentary on F19 vs Gold Bug Pro. Link deleted since Findmall update broke all old links If they came out with a black and gold version for $100 less they would get me. -

Daniel has very bad ground and basically hunts like a nugget hunter would. He uses all metal or a PI very often. He generally has little use for discrimination. Discrimination circuits are only accurate on isolated targets in the air. As soon as you add ground mineralization, the numbers start to change, and if you co-locate other metal items - game over. The most common observable effect in mineralized ground is the target number being pulled down the deeper the item is, until it is identified as ferrous. The layman explanation is that the detector sees ground iron mineral in greater quantity than the non-ferrous item, and there is a point where it sees so much ferrous mineralization it calls the overall signal ferrous. All VLF detectors do it. How much they do it is governed by the ground itself, the target, EMI interference, the angle the target is buried at, and the detector itself - frequency, ground balance method, discrimination methods employed, and especially the coil all are part of the equation. Daniel and I have compared notes. He will have little good to say about any unit using discrimination. He prefers all metal, and he has had best results in that regard with the Fisher F75 and White's V3i. He is not as thrilled with the new F75 all metal mode, and the Nokta he has issues with the machine resetting and interfering with the way he is used to sizing targets. You can go to the Dankowski forum and read his posts over the years here http://www.dankowskidetectors.com/discussions/search.php?2,author=163,match_type=USER_ID,match_dates=0,match_threads=0 All VLF detectors do it and it is part of the basis for my article Metal Detector Discrimination Really Sucks I also cover in many other posts and articles like my discussion of the MXT at Ganes Creek near the end of the page at http://www.detectorprospector.com/gold-prospecting-equipment/whites-electronics-mxt-metal-detector.htm The bottom line is I have not found any detector to stand out as truly the best when it comes to accurate AND deep discrimination. You can get good discrimination, or good depth, but not both. It does vary by location so what works great in one place does not work so well in another location. Leading to many online detector wars! Ground mineralization tends to pull target id number down, also referred to as down averaging. Interestingly, lots of man-made ferrous stuff in the ground, like tiny flakes of old rusted cans, etc. can also cause id number to push up, or up average. This can be used by designers of a machine like the DEUS to good effect. It is very good at finding non-ferrous items in a pile of ferrous stuff, and I believe it is because it uses this up averaging tendency to a degree. Yet the DEUS is also notorious for having inaccurate id numbers. The Minelab BBS and FBS machines probably have the most accurate and consistent target id numbers that can be had for as deep as you can get them, but the reality is they are not very deep machines in highly mineralized ground. But when they call something good, it probably is. I spent a lot of time over the years trying to find a detector that got good id on non-ferrous stuff like gold in mineralized ground, and generally the mid-frequency gold detectors with good tight DD coils are best, and smaller coils are better than larger coils. DD coils will also call lots of ferrous stuff like flat steel non-ferrous so you dig lots of junk also. If you have a unit that has you digging no ferrous stuff you are sure to be missing non-ferrous items also because the unit is biased that way. If pressed I would make a case for the MXT in relic mode being one of the better choices along with the F75 and T2. Tesoro Tejon has a good rep there also but never used one myself. Long story short they all do it and some are better than others, but it depends on the ground you are in. There flat out is no good answer and I immediately become suspicious of anyone making claims to absolutes on this subject. I can say that the jury is out on the Nokta in that regard. I would like to do more direct head to head work with it on my ground but need more time. My last serious outing was with the DEUS, Gold Bug Pro, Nokta, and CTX 3030 in bad ground looking for non-ferrous targets in ground loaded with ferrous junk. My issue with the Nokta was not so much it calling ferrous items non-ferrous but just the opposite - it was calling lots of ferrous stuff non-ferrous, but in a mixed sort of way. The CTX darn near eliminated the ferrous stuff but seemed too aggressive. The DEUS did fine but the Gold Bug Pro was nudging it out by a hair for depth. Do not read too much into what I just stated - it is just one run and far from definitive. At the end of the day the more tests I do the more I just learn that discrimination sucks. All it is good for is cherry picking or at best in helping decide where to focus on usng a PI to dig everything. I can sum up by basically agreeing with Daniel. Use a Nokta in disc mode and you will miss gold. As you will with anything else. Use discrimination wisely and at your own risk. Fairly detailed article on the subject as relates to the DEUS at http://www.metaldetectingworld.com/xp_deus_coin_vdi_readings.shtml A quote from that page "Cases when the target's VDI value turns out to be 10-20 points lower than a "normal" readout are not as bad as the cases when the non-ferrous target's VDI reading can not "bail out" of the iron range on the Conductivity/Discrimination scale. As a result, such low-conductive valuables end up being rejected."

-

Garrett ATX Strip Down & Rebuild

Steve Herschbach replied to Steve Herschbach's topic in Garrett Metal Detectors

Oh oh, did not think of that! OK, making progress. The control box enclosure has been shipped. The coil is basically done. Surprisingly the cable on the stock coil when made straighter is the same length as the Infinium coil cables, which are designed to be hip or chest mounted. It is about 6.5 feet long. Plenty long for chest or hip mount applications. The downfall of the ATX as far as weight is the stock coil. Even stripped down it is an epoxy filled coil and so on the heavy side. Mounted on the White's rod assembly the entire thing with scuff cover installed weighs 3.2 lbs. This is a dream compared to the 6.9 lbs of the ATX in full dress, but it is nose heavy. I planned on mounting the control box under my arm but I think the position of the hand grip is such that it will still be nose heavy. It should work perfectly with the Infinium 5" x 10" DD coil. It would also be good with the ATX 8" mono coil but I am still being too cheap to buy another one to cut down. I just may do it though. I would not need to modify the coil pivot as it is less an issue with the 8" coil. I would lose the discrimination ability but it would match the depth of the stock coil and still be lighter. When I get time I will do some serious depth tests on the stock coil versus Infinium coils to see if they keep me in the ballpark. If not, I may have to get another mono coil. Maybe I can talk Garrett out of one in the interest of science! In any case, with my GPX 5000 heading out the door I now have a fiberglass upper rod sitting idle. I just ordered a Minelab handle for it, the earlier version without the button on top. This will give me a straight rod assembly instead of the S-rod and allow me to mount the handle far enough forward to balance with the control box under arm. Gee, see why Minelab did that? This is shaping up well enough I may not actually do any hip mount work but if I do the White's handle still might come in handy as I like S-rods. At just over 3 lbs if I can keep control box under 2 lbs I just might squeeze in under 5 lbs with the stock coil. Let's just call it five pounds, so I will have shed 1.9 lbs. The real key to getting the weight down is a lighter coil. A non-epoxy filled version of the stock coil would be best - I will cross fingers for the aftermarket to provide me with a miracle. Or an 8" mono. But if I can get this baby down to 4.9 lbs with the stock coil but without the scuff cover I will be very happy. That would be a solid 2 lb weight loss or 30% less than the ATX as shipped.