-

Posts

2,457 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by jasong

-

Thinking on this thread and Jim's experiments a bit more, I think I'm going to leave the drywasher at home though. Seems like the best (simple) way dry is just a 20 mesh hand classifier to get rid of silt, a 3/8" to get rid of the oversize (I don't predict any gems larger than 1/4" here), then dump all the oversize onto a big tarp and just smoosh it out by hand and look for anything shiny, colorful, or out of the ordinary and pick it out with fingers. Or, just bag up all that classified material and run it through my Gold Cube at home later if that cut is small in volume and easy to collect/transport.

-

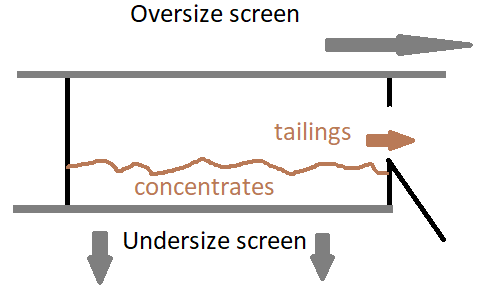

Hi Jim, thanks for the responses. What a coincidence that I see your video and you not only happen to be working in my part of the country but also a member of this forum! This was the part I had a question on, but after a bit of sleep I may have answered it myself. In your videos you said the jigs work great on gems, but then later change your mind and say they don't work. I am guessing what you meant in the videos is that they work great on gems when running wet but that they don't work well running dry? It's definitely a classifier, but it's also vibrating/jigging so the idea is that if the gravel is classified in a way such that the average size of the gems is always smaller than the average size of the gravel, the granular convection effect will actually help since it will keep the smaller particles at the bottom (gems) and the larger particles convecting up to the top (gravel). The oversize classifier lets in gravel bigger than the largest expected gems, the undersize classifier removes the smaller gravel/silt so that the gems are now among the smallest particle size in the mix. That's the theory anyways. Of course, you can never know what sizes of gems you might be recovering so there will be gem losses out of the bottom classifier, and in some cases you might lose a really large gem too if it's close in size to the largest gravel, and so this idea would not work well where the sizes of the gems is mostly tiny or highly variable. But in areas where say most are bigger than 20 mesh, but smaller than 1/4", then they should not convect up to the top if you have gravel up to 1/2" in there as well. So, it's a matter of strategically selecting screen sizes. Also, the undersize screen will also basically "deslime" all the silt and whatnot out, an added benefit for later cons cleanup. That's the idea anyways, of course ideas never work as expected when put into practice and built. It'll have to be a winter project for me as I don't have enough time right now to build such a thing to see if it'd work or not. Interesting, can you elaborate on that a bit more? I watched your vid on the circle jig and GC seemed to still be occurring, it must be another shape? Or potentially it reverses at the edges? Well maybe see you out in the field sometime, if I get some kind of machinery to actually work you could come take a look. We'd probably have a lot to talk about.

-

Here is a very crude drawing to illustrate the idea of using granular convection (aka 'brazil nut effect') as a benefit, instead of a hinderence. This is what I'm wondering if Jim experimented with. The idea being this: let's say your gems are on average no smaller than 20 mesh. And on average no larger than 1/4". You'd set your bottom screen to be 25 mesh and your top screen to be 3/8"-1/2". The vibrator on the jig should automate the screening process too. So, now the granular convection "problem" may actual help. Because the gems will among the smallest gravel sizes and thus will not convect up to the top with the larger pieces. The larger pieces should act to keep the smaller gems buried and in the jig. As long as the gems are always smaller in size than the average gravel pebble, granular convection should actually increase the efficiency rather than decrease the jig efficiency. At least in my head that seems like worth experimenting with. I think the key would be proper screen selection for any given environment/targets. Further, there is also the standard jigging concentration effect going on top of that too. Seems like it should work? The undersize could be bucketed and run at home in a sluice if losses are a concern, the oversize should be able to just be eyeballed.

-

Interesting. He keeps saying it works great with gems, but then has a comment in the description saying it doesn't work. Why? I can't help but feel the author of that video might be a forum member? He's probably exploring some of the same areas I am anyways and that avatar seems familiar like I've seen it posted here, he also runs a TDI SL so I'm guessing he reads this forum at least. Granular convection is a problem with size sorting, so I guess a solution might be to classify strategically such that the average size of the gems is close to the smallest size particle in the gravel mixture. "Overclassify" I guess, which is sort of the opposite of what you'd do with a wet jig. I'm guessing he's already tried that though. I'll have to dig through some more of his videos when I get time tonight. Edit: @Jim in Idaho I thought I recognized the avatar. Care to answer some questions on gemstone recovery and jigs?

-

In my head what I'm thinking to create a mechanized, dry version of that hand jigging concept is something like a big vibrating 2ftx3ftx6" deep tray with air at the bottom (like an air hockey table). No riffles, just a tray set flat and level and maybe some small recesses ("nugget traps"), with a grizzly on top to shovel onto/classify. Let it run for 15 or 20 seconds then run a flat bar across to take the top half of the gravel off, then shovel into again and repeat the process. Similar to a drywasher I guess... But seems to me the closer in SG the gems are to the average SG of the gravel, the flatter you'd need to run, so running completely flat seems best and get rid of the riffles entirely? I guess you could call it a "dry jig" - not quite jig and not quite drywasher. Basically fluidized and always just removing the top cut of gravel out of the tray, leaving the bottom cut to continually concentrate. Light sands might just naturally overflow off the sides too, as new gravels enter the tray, not sure. Maybe try out one of these new battery powered leaf blowers to make it more portable. Hmm, sounds like a winter welding project.

-

Interesting, never considered a hand jig like that. I'm going to have to think on that concept a bit and see if there is some more portable, mechanized way I could build something like that. In my mind it seems like the jigging is just fluidizing the gravel, so I should be able to accomplish that with dry gravel too as long as I can fluidize the gravel - like with air/vibration. Which I guess is basically what a drywasher does. I'll give the drywasher a try for lack of anything better right now, if it's catching the garnets then it should catch diamonds and sapphires too I guess. The issue for me is total lack of water, I'd have to haul it around with me on my ATV, so for exploration working dry methods seems required. If I do find a place worth working, I have 2 duplex jigs that I bought years ago to refurbish and stopped halfway through due to lack of any real place to use them. These suckers are 600lbs each though, not something to move around a lot.

-

I'm planning on doing some gemstone prospecting here soon. I know I can more or less dry pan for diamonds and sapphires, but I'd like to move a bit more dirt, like 1/4 yard test holes in washes, 4-5 test holes a day. I need something light and portable (ATV packable). Lacking any other ideas, I'm just going to use my drywasher. Is there anything better than that?

-

Various chunkier pieces from the first season the GPZ came out 2015. A little over 1/2lb in my hand there for a family photo before I sold most of them off. 18 ounce winter season total. Every season since then has been less and less. ?

-

My concern with the AR plate in the mill was brittleness, wasn't sure if it'd be better to go with AR or hardfacing in applications like that, though I guess hardfacing is probably more brittle than mild steel too. Any reason to tie both chains together with a single plate vs go with 1 plate per chain end? Mine has 4 chains inside like yours. I need to cut up some of this AR500 and just give it a try. I constantly wish someone would build a better Hermit pick here out of AR instead of the shovel material that basically lasts 1 season.

-

Is the impact mill not leaving a fairly consistent 150-200 mesh powder when you use a plate instead of just the chains? Just curious why the roller mill is necessary at the output. Mine basically leaves all the ore (except the gold/native copper/other malleable metals) as a consistent flour. I bought some AR500 plate (roughly same hardness as hardfaced welding) to put on the chain ends, but now I'm wondering if that is going to result in a chunkier output that needs further processing?

-

Do you use grade 8 chain? Tried AR plate for the flail ends by any chance? I have an impact mill I built some time back almost exactly the same design. Keep meaning to try out some different metal in it but then just throw more chain on to get a job done and forget about it again until next time.

-

Crazy, I found golden crown too years back, mine came from a backyard though, I'll see if i can dig it out to add to the photo collection here when I get back home. How are so many people losing crowns, getting in knockout brawls or something?

-

How Many Hours Do You Detect A Week/month?

jasong replied to mn90403's topic in Detector Prospector Forum

50-60 hours a week prospecting, basically wake to nightfall every day when I'm out. Sometimes it's mostly detecting, sometimes it's mostly exploring. That's just when I'm in the field though, I spend about 50% of my time in town running another business that has nothing to do with prospecting. The difference in time spent using equipment between people kinda does drive home the point why some feel so much more passionately than others about having equipment working properly. A little lump in your truck seat isn't a big deal when you drive 15 minutes to work, but start spending all day driving cross country for a living and dealing with that lump constantly and it turns into a problem. -

Do you mean they are doing something like using an inverse Fourier Transform to construct a new time domain waveform out of a number of multiple additive VLF frequencies broadcasted by the coil, and then sample for the target response after the new FFT "pulse" is decaying? But still also sampling in the frequency domain too with the multiple VLF frequencies individually? Or are you talking about something more basic here? I get confused between the way physics/mathematics terminology is used sometimes in the detector world in ways that don't mean what I would interpret them to mean outside the detector realm.

-

I called it my Dragon Boat Nugget. I've found crystalline, dendritic, cubic, octahedral, wire, leaf, and every other type of nugget out there, but never one like this. I sold it back in 2015 for spot along with a lot of other unique gold because I needed gas money to get back home. Many regrets. If someone here bought it from the dealer I sold it to, I'll definitely buy it back for spot. ?

-

Amazing stuff and a great report. Sometimes I read some of these 100+ year old reports from various areas where they talk about the miners taking out 5-10 ounces a day with a rocker or by pan and it seems some are exaggeration. But 1/10th of an ounce in one pan off false bedrock there shows it's possible in the right untouched ground.... Also goes to show just how useful a metal detector can be in the right hands for commercial operations and exploring. Easily the most underutilized tool in the commercial prospecting/mining world right now I think.

-

You use a 26" concentric coil to prospect for new ground? You must have a fair idea you are in ground where gold has been found already then?

-

Welcome back.

-

Same. I'll probably get one of these Manacles though, I've been waiting for whatever the EQ800 successor is so I can buy my last VLF and move into the world of target ID like a normal, modern human, this looks close enough. GPZ 7000 and GPX 6000 were starting to sound way too futureman technonerd for my tastes anyways. That's too many thousands for me. I for one am happy to see the Manicure reverting back to old school fantasy-based nerding again.

-

Found Some Items Not Sure On Age Or What They Are

jasong replied to Dil's topic in Metal Detecting For Coins & Relics

The iron or brass object appears to be either part of an old style door handle - the sort you open by pressing your thumb on a lever - or some kind of similar thing where you press your finger on a lever to move some mechanism at the other end. -

Aftermarket GPX 6000 Locking Stem Kit Fitted And Tested

jasong replied to Aureous's topic in Minelab Metal Detectors

It must be low manufacturing tolerances because my 6000 shaft doesn't twist. I tried twisting it by hand last trip out just to make sure I wasn't crazy, and it was quite hard to turn. Yet my 7000 shaft twists every 5 minutes, and that's the replacement shaft they sent to fix my first twisting shaft. Yet another of those problems that seem common for some but not others on the 6000. Seems to indicate a problem with manufacturing consistency. It makes me hope that new detectors aren't made at the same factory, or this might become situation normal in the future. -

Looks like some sulfides in quartz and maybe some type of cherty limestone host rock. Hard to tell from photos, especially on my small phone. Chalcopyrite has a greenish black streak, pyrite has a brownish black streak, and galena has a gray streak. Best way to tell the 3 apart. A small streak plate is a great inexpensive investment if you are identifying minerals.

-

Haven't had a chance to test, I'm stuck in town working for another week at least. I'm pretty sure it isn't the issue though, it doesn't explain why the 6000 works fine at some locations, but not at others - every time I revisit. Or why it loses stability with both coils - my 11" was definitely tightened on as far as it would go, and the 9" connector only moved a fraction of a mm. Haven't heard back from ML yet either.

-

Things I Don't Like About The Garrett Axiom

jasong replied to Gerry in Idaho's topic in Garrett Axiom Forum

Micro USB is the one that failed a lot and gave USB a bad durability rap. USB C is pretty dependable. I have USB outlets in my truck, ATV, SxS, laptop, battery booster, and you can also get a cable at just about any gas station these days too. Not to mention most generators and inverters have USB ports built in now too. Good addition IMO. Coin detectors used around town are one thing, field detectors used in the boonies should be robust enough to take charge from whatever is available, and the most universal port in the world is USB C right now. I'll go 5-6 days at a time where that's the only power I have. Similarly, headphones might be more necessary for coin and jewelry detectors where you want to be quiet in parks, or cover up the sound of the surf. But every prospecting detector should have a speaker IMO. People spent so long with the SD's, GP's, and GPX's being more or less forced to use headphones that I feel many just assume it's a necessity for accurate detecting - it isn't, as long as the wind isn't ripping. The Axiom IMO is incorporating design elements necessary for a real field machine intended for prospecting in the boonies, as it should be. Having not used it yet, the only thing I can see that I dislike so far is what seems to be a premature announcement of the machine itself. Excitement wanes after a few weeks, and while it's nice to read field reports from testers, at some point its just like...ok, but when do we get a turn? -

You and I and people like us paid full price. But before that time even there were people paying far less, we just didn't know it then. ? I felt so stupid and embarrassed the day I discovered that basically everyone around me had paid way less than I did for every detector I ever bought, or that you could even negotiate the price down in this game. Especially since I was living off Ramen and that extra thousands in savings at the time would have been a massive amount to me and kept me in the field a lot longer instead of having to drive home and go work and waste valuable time to replenish the savings while I taught myself how to prospect profitably. I had never bought anything from a dealer before that point, as all my vehicles were just junker used trucks, I had no idea anyone would actually negotiate down a retail price in the US for a new item, I assumed they were just set in stone since I'd never seen any different...I didn't go negotiate a Big Mac any more than the local computer shop would negotiate the price of a new graphics card back then either. The thought that I could even try to negotiate a metal detector price never occurred to me until someone finally told me that was the normal game. It still to this day makes me cringe and feel stupid when I think back to how much money I wasted, especially in those days I could least afford to waste it. So yeah, today, price is the only thing that matters to me.