Search the Community

Showing results for tags 'rods shafts hardware'.

-

I think I'm going to need to invest in the tall man lower shaft for this E trac, I'm 6' 4" and I have the lower shaft extended as far as it can go and its wobbly now ....

-

I am one of those people who have always found the armrest of the Garrett Ace and AT models to be just a hair short for my liking. This would include what I’m seeing on the new Ace Apex. Years ago a guy was making and selling an item called the Garrett Gizmo, a machined metal extension for the armrest. It not only made the armrest longer but acted as a counterweight making the detectors less nose heavy. Unfortunately he must of machined up a limited number, as there are no recent internet references that I can find. It seems to have disappeared. Does anyone know where to get one of these or something like it? If not, here is an accessory sales opportunity for somebody. Garrett Gizmo

-

I'm not shy about it. Yup. I have big clumsy feet. The good news is it gives me stabilizing ballast should sobriety forsake me. The bad news is it's hell on GPZ 7000 lower shafts. I have broken several. To make matters worse, the lines of communication between my big feet and my small command and control center often get disrupted somewhere between my gullet and my gizzard which allows my big feet to proceed on a different heading than the rest of me. Oops, there goes another GPZ 7000 lower shaft. But I don't take full responsibility for all of these broken lower shafts. I don't recall ever breaking the good ol' GPX lower shaft and they fit at least 10 different detectors and cost less than half of a GPZ lower shaft. So I lay most of the blame at the feet of Minelab and not because of the feet of Klunker. The shaft is just plain flimsy. Being a "tight wad" by nature I have tried numerous times to repair a broken lower shaft using glues, epoxies, tape, splints and every flavor of bubble gum you can imagine. Nothing worked. I finally came up with the idea of totally replacing the lower end of the shaft and it work splendidly. This was made from an inch and a quarter by 1 inch pvc plastic pipe tee, a fine toothed saw, a drill, a round file, a sander, a heat gun and a bit of good epoxy. This repair has held up for a couple of dozen trips and survived the icy conditions of early spring detecting, which is when my big feet are at their worst. If anyone is interested I will post instructions

-

After using equinox for a year and a half on the beach, I thought it was time to use it also in the mountains, if on the beach the original rod can be fine, in the mountains it is very uncomfortable, I thought of finding a way to reduce it, I had a photographic manfrotto with almost triangular rod, the upper part of the equinox electronics could adapt to the rod but the lower part did not, I looked for something at home that could replace the lower part, an easily foldable aluminum sheet and four knob screws obtained from connectors F for TV and brass screws, in order to easily detach it, the coil attachment and the shaft are of an ace250, the result can be seen in the photos, 570 mm long, easily transportable, it could have been done better but I don't have a 3d printer . Now I have two Nox800s, one for the beach and one for the mountain.

-

I know there's a long and old thread discussing this topic and other Equinox ergonomics but I decided not to bury this post there. In the last few months I've had some minor issues with the elbow on my swing arm ("tennis elbow" according to my doctor) but worse, recently I've been having wrist pain on the same arm. I don't know if the latter is related to detecting but it reminded me of the above linked discussion (and others) about S- vs. straight-shafts. I don't know if the mod I now describe is new. (After 2 years in the users' hands I would have thought not, but don't recall it on this site, anyway.) Here's a picture of the almost finished garage mod: In a nutshell, I've replaced the two lower sections of the Equinox shaft with the two lower sections of the Minelab X-Terra shaft. Now I'll start at the bottom and work my way up, describing the differences. Coil to shaft attachment: Surprisingly (because it seems like Minelab changes dimensions, etc. on every new detector) the gap between the ears is almost a perfect fit. It seems to be slightly looser with this mod, but that may be simply due to wear on the gaskets. I measured the shaft's widths and they are very close, possibly about 0.005 inches (~0.1 mm) different. Different gaskets or just a metal or plastic shim could tighten things up, but for now I'm not going to do that. Next is the screw/bolt and nut. The X-Terra had a nominal 1/4 inch diamter bolt while the Eqx is larger, (I think it's 8 mm, slightly larger than the SAE 5/16 inch). Again, until I find out otherwise I'm not going to be concerned about this as the smaller bolt goes through both parts just fine. Lower shaft section composition: The Eqx has a carbon fiber lower shaft section whereas the X-Terra has an aluminum shaft with a plastic extension/insert for the coil attachment section. I did a quick test-garden check and the mod didn't appear to give any deterioration in performance. 5 in. deep penny and 6 in. deep US nickel, in moderately mineralized soil, I could turn gain down to 5 and still (barely) hear both in Park 1, recovery speed = 5, Iron Bias F2 = 5. Again, at this point good enough for me. Middle shaft section: This is the S-section. The smaller diameter of this part is why you can't use the Equinox's lower section -- its diameter is too large to mate with the X-Terra S-section. Middle shaft section (X-Terra) to upper shaft section (Equinox) mating: This is where things get a bit more complicated. The O.D. of the X-Terra shafts is right at 3/4 (0.75) inch whereas the Equinox is ~0.78 in. This 0.03 (~3/4 mm) difference is not acceptable as is. I used 0.0015 in thick copper tape to build up the X-Terra shaft. The tape's adhesive adds some thickness as well. I needed 15 inch length of tape for a complete wrap to make up the difference. (Note: I'm going to add another equivalent wrap above the alignment pin as well, but as of now -- shown in the photo -- I only have the one wrap.) Next, note that the X-Terra has two alignment pins compared to the single one for the Equinox. Turns out they are 90 degrees out-of-phase. In addition, the pin size (and thus hole diameter required) is different, this time slightly larger on the X-Terra. I'm going to drill two opposing holes in the upper Equinox shaft. Again it appears that the X-Terra was made to SAE dimensions and a 1/4 inch hole is the right size. To make sure I don't get more hole than I need, and to avoid the sloppy 'triangular' hole that standard jobber drill bits tend to make in thin sheet metal, I've ordered a 1/4 inch reamer from Amazon for the job. Weight difference: The X-Terra lower sections and the attachement bolts & nuts are 80 g. (~2 2/3 oz. or ~0.2 lb) heavier than the equivalent Equinox pieces. I assume this is due at least in part to the carbon fiber composition but the tubing (and other pieces) may also be contributing. Potential concerns: I start by pointing out that I'm not a beach/water hunter. Apparently the drag, etc. in that form of detecting puts more mechanical stress on the connections and parts in general. In particular, drilling two more holes for the alignment pins in the upper section shaft (which unfortunately are located right at the same location as the already present hole) will result in a weakening of the shaft there. I don't think that will be an issue for me, but water hunters (who apparently prefer straight shafts anyway) could be scared away from this mod. I suppose one might be able to buy a replacement upper section from Minelab.... Those holes are the only thing that keeps this mod from being purely 100% reversible and assuming they don't result in future breakage, I have the best of both worlds. (Of course it helps to have an X-Terra sitting around collecting dust!)

-

Hi all!I wanted to give an update on the GARRETT shafts (middle and lower sections) that I've been working on, at Steve's Detector Rods. The first batch of 10 prototypes are complete (I made them in four different colors -- black, green/black, red/black and blue/black), and I am VERY pleased with the result -- I think they have turned out great! The two shaft sections are connected by one of my heavy-duty clamp-type cam locks (as used on my Equinox shafts), which eliminates the twist-lock and the spring button/button-hole design that is used for attachment of these two shaft sections, on the Garrett shaft.AS A RESULT, my shaft offers four benefits over the stock middle and lower shaft sections... LIGHTER WEIGHT. My carbon-fiber middle and lower shaft sections offer a 20% weight reduction over the stock Garrett middle and lower sections. (My two-piece shaft weighs 5 ounces +/- .1 oz or so, whereas Garrett's two sections weigh 6.1 ounces +/- .1 oz or so). FASTER/EASIER INSTALLATION AND SHAFT LENGTH ADJUSTMENT. With no twist lock and no spring button/button holes to fumble with, attachment of the lower shaft to the middle shaft is quick and easy; simply flip open the clamping lever on the cam lock, insert the lower rod section into the middle shaft section, and lock the clamping lever closed! UNLIMITED ADJUSTMENT LENGTH OF THE LOWER ROD SECTION. Again, with no spring button/button holes on the shaft, you can quickly and easily adjust the lower rod to ANY desired length, as opposed to having your lower rod adjustment length confined to pre-determined button-hole locations. IMPROVED AESTHETICS/VISUAL APPEARANCE. The high-quality, attractive look of carbon fiber offers an upgrade the look of your Garrett machine. And, you can add even more visual appeal -- making your AT- or Ace-series machine really "stand out" from the crowd -- by choosing one of a number of custom colors for your carbon-fiber shaft. A green/black prototype shaft is pictured, below! If you have any interest in upgrading to a carbon-fiber shaft for your AT- or Ace-series machine from Garrett, contact me via PM, by email at steve@stevesdetectorrods.com, or via Facebook message (www.facebook.com/stevesdetectorrods).THANKS!Steve

-

I often hike the woods to get to old home sites, so I carry my detector and gear in a backpack. Rather than disassembling and reassembling every time it’s much better to have something that allows you to collapse or fold the detector so that it will fit in the backpack, and also take less time to get ready to use or pack up. Of the two types-telescoping shafts, and folding shafts, I think the folding is better. First, it costs less, about $50 for the part. Second, it takes one motion while depressing a button to get ready for use whereas both ends of the telescoping have to be unlocked positioned and locked again. Also with folded, the height is always maintained- not so with telescoping. The folding unit adds about 5 oz of weight to the lower mid section, but is not significant. As for strength, I’ve not noticed any slack or wobble at all. I only bring this up for those who want a collapsing detector to show there is an option other than the telescoping ones advertised. And also to say I think the folding style is in my opinion better. What do you think?

-

Can someone post the lengths of the upper and lower rod to the GP5000, thanks.

-

Hi, all! I just wanted to mention that in the spirit of the Holidays, Steve's Detector Rods will be giving away one carbon-fiber complete Equinox shaft (upper shaft and lower rod), AND one carbon-fiber Equinox lower rod, to two lucky U.S. winners. Two separate drawings will be held on Dec. 18, one for the complete shaft, and a second for the lower rod. Entry into the drawings is completely free, with no purchase required -- and the entry period is open from now, through 11:59 PM on Sunday, Dec. 15. Additionally, ALL entrants into either drawing will qualify to receive 10% off of any item purchased through Steve's, for the entire month of December. For additional information, including details and eligibility, please visit Steve's Facebook page, at https://www.facebook.com/stevesdetectorrods Thanks! Steve

-

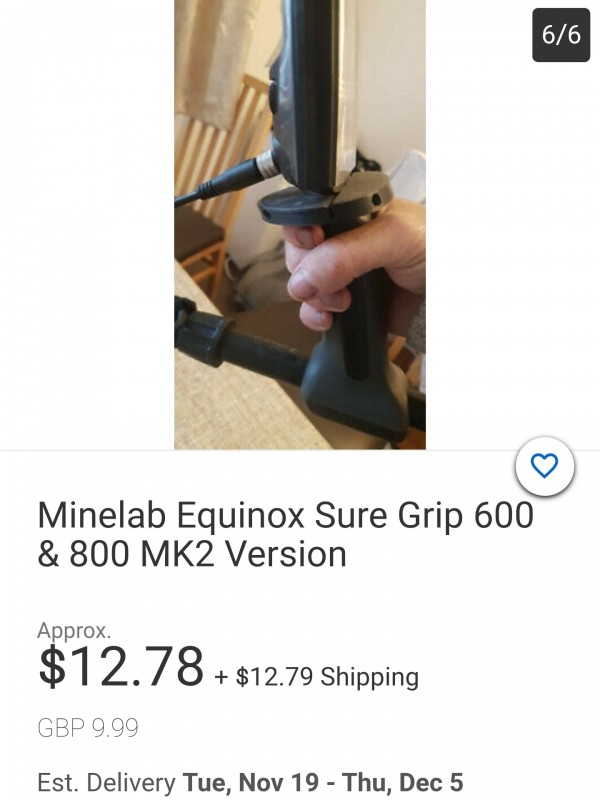

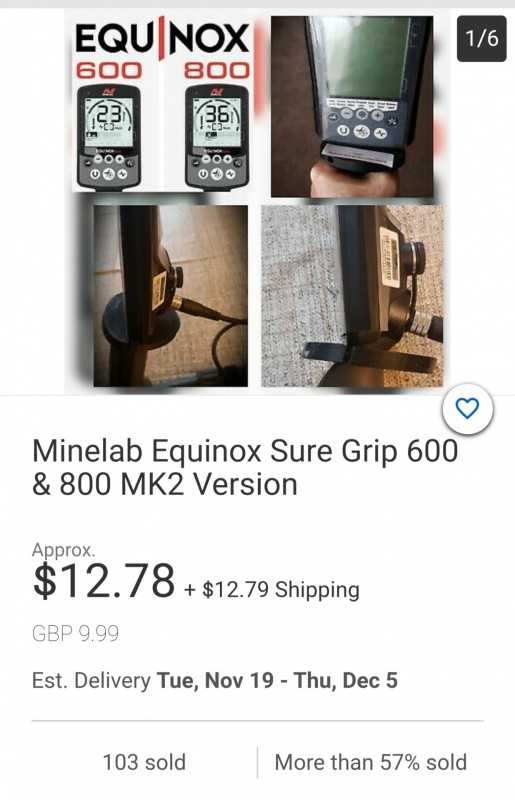

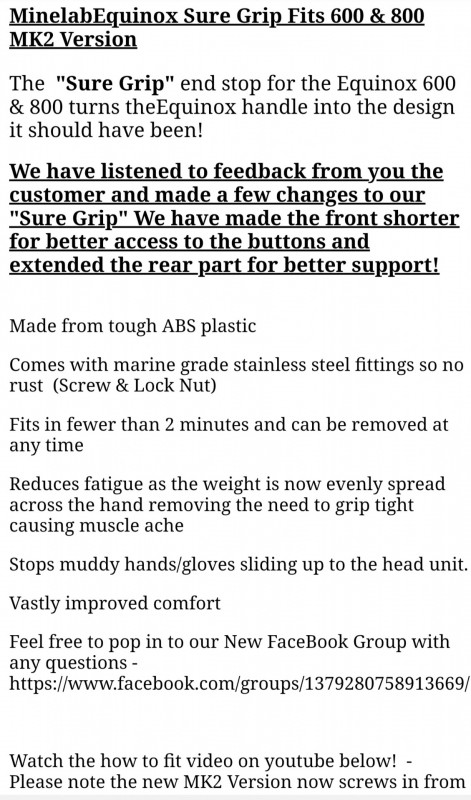

Have been looking at this on Ebay and decided to order one today to try out! We will see how it functions! I currently don't have a proper shop, or else i would probably make one myself, out of an old nylon cutting board! If it works out, i may make a few for my other detectors! But for now, I'll just purchase!👍

-

-

I don’t really like the smooth handle on my Equinox so I wanted to add something to give it a little more cushion and grip. I first thought of handle bar tape like they used on ten speed racer bikes back in the day but nobody seems to carry it, except maybe a bike shop. Besides, I thought it might have been too thick. I settled on cloth Athletic Tape that I found at Walmart. It’s super thin, 1.5” wide, has a sticky back and only cost $2.97. If it gets torn or dirty, I can just change it like a bandage. I figure I can get about 15 applications out of the 30’ roll!

-

Has anyone ever made a homemade shaft for a metal detector with PVC pipe ? I think im gonna try it ill keep you informed on how it goes

-

Since people are chatting up new stems, I would like to recommend a three piece telescoping replacement for the stock Equinox stem. I received it today and love it. It is super lightweight, simple to assemble (I did it so it's simple), it obviously has had a lot of thought put into it. I don't make a habit of putting up ad's for equipment unless I am pretty sure they are first rate and I believe this shaft meets that standard. I took a couple of quick shots of it after I closed it up to it's shortest length. They also included a nice cover for the Eq. control box which I also have shown. Take a look at their website and see what you think https://www.detecting-innovations.co.uk/TELE-KNOX_Detecting-Innovations_Telescopic_Stem/p6292256_19741720.aspx

-

Hello everybody, can I use the Golden Mask Shaft (converted for the Equinox) in salt water? Are there metallic parts that will be corroded / oxidized by being submerged in ocean/sea ? Thanks Editor's Note - this thread was split from an older existing thread about the Golden Mask aftermarket rod

-

Took my new set up to the beach for a few hours for their first trial run as a “team.” Steve’s Detector Rod. This two piece shaft was the best I’ve ever used...bar none. It was solid as a rock, as in no wobble whatsoever, and light as anything I’ve ever used. With the counter balance weight, it was better than swinging my old Deus with a 9” coil. Steve weighted mine using 16 oz of lead shot in a 4.5” long cylinder. He set it up that way so swinging the 11” coil would emulate swinging his 7 oz shaft with a 6” coil installed! It works exactly as intended and designed. Bottom line, I couldn’t be more pleased. This will be my shaft of choice for the very very long term. You can read my original review of Steve’s work at the link below: Quest APTX-LL Wireless Headphones Initial thoughts: My order only took two days to arrive from Hong Kong! Extremely comfortable over the ear design. External build quality looks good. They paired up with my EQX exactly like the Minelab wireless even to the point of using the same tones as the Minelab. Low latency capability is certainly there. I ran them in my test garden using good targets surrounded by iron and they performed extremely well. Nice and clear crisp sound with sufficient volume. Haven’t yet had to use the volume control. Haven’t been able to test battery life yet so that’s TBD. So far, I’m favorably impressed. I’ll take them to the beach on Monday and report back. Additional points: ~ These headphones are easily adjusted for proper fit and the top head piece is extremely well padded and comfortable. ~ They are water/rain resistant. Not designed for diving...and resistance to water damage is all I really wanted. No blue tooth wireless headphones can be used when submerged...at least none that I know of. Fast forward to their first beach run. We finally have a set of Aptx low latency water resistant headphones made specifically for the Equinox! These headphones again linked right up with no issue. They were indeed low latency and I was able to pin point with ease. The sound was clear and crisp as I stated above and their over the ear design served to block out much of the ambient beach noise. They proved very comfortable after 3+ hours of detecting and simply worked flawlessly. I love being “untethered” and confident that when one of our Florida showers come up, I won’t have to worry about these getting wet. Again, they are water resistant not water proof. They are advertised as having a 24 hour battery life so I’ll not be able to comment on that since my hunts are never that long! One thing I took note of was, as is true with most or all wireless set ups, every now and then I would hear just a hint of static interference but it was barely noticeable and very rare. I attributed this to EMI since we were very close to Patrick Air Force Base and its Officer’s Club Beach. I’ve experienced such EMI there before. Bottom Line: I like these headphones very much and you can find them at the link shown below. https://www.questmetaldetectors.com/product-page/aptx-low-latency-bluetooth-wireless-headphones-for-minelab-equinox I now have what I believe is the best set up for my style of beach hunting. The Equinox, Steve’s rod and Quest wireless Hps. Soldier on...

-

I recently installed one of Steve’s Detector Rods on my Equinox and wanted to share a few observations. When I’m particularly impressed with a product, I like to let the maker and others know my thoughts...good or bad. The first impression out of the box was very positive. The build quality of this two piece system, both material and workmanship, is absolutely excellent. The cuttings are smooth and the fittings precise. You can immediately tell Steve uses only the best materials in the overall construction. Being a scientist, his penchant for precision is obvious in everything he does. Another very important fact about Steve—he’s a one-man-shop small businessman and an avid detectorist who knows what we need from personal detecting experience. Now for a few specifics. The locking mechanism is extremely sturdy and I really appreciate his use of an adjustment knob instead of having to hunt down or carry a screw driver in order to adjust the locking tab tension. I quickly noticed another user friendly design feature on Steve’s part. He uses easily found round washers on the lower rod where it connects to the coil ears! I don’t know about you, but I was amazed at how expensive those tear drop washers are when or if they ever need replaced. Thank you Steve! Another unique offering of Steve’s rods is the available counterbalance weight. As many have commented on these forums, the Equinox is inherently nose heavy...particularly with the 15 inch coil. Although his shafts are extremely light in their own right, a mere 7.86 ounces of combined weight of the two shafts, the counterbalance weight makes a huge difference in the perceived weight. When you first look at this counterbalance weight you may think that it only serves to add more total weight to the Equinox...and you’re right. However, when I installed that weight on the back end of the shaft, the balance was markedly improved...balance being a key factor of perceived weight. The designed fulcrum effect makes the detector simply feel lighter and makes it much easier to manipulate. I’m sure I could swing this Equinox for hours, even without the use of a harness, and my arm would be just fine. The stability of this set up is incomparable...and I’ve used many shafts on many detectors over many decades of metal detecting. One design aspect that may go unnoticed is that Steve’s lower shaft is 1.75” longer than the factory shaft—and he can make them longer upon request. This simple idea allows more of the lower rod to remain in the upper shaft giving it added stability even at extended lengths—not one wit of wobble with this one! An aspect I also appreciate is the elimination of the restrictive spring button adjustment system. The button only allows you to adjust the shaft to a factory predetermined series of lengths. Steve’s approach allows you to adjust the shaft to any length with which you feel comfortable. This guy has really thought the design through and focused his efforts on all those “little things” that make a big difference. Steve offers his shafts in an array of colors. Black, Red, Blue, Green and Silver. He can also provide custom work on his shafts if that’s what you need! Who else offers that? I’m obviously impressed with this young man and his workmanship and I like to let folks know when I find an outstanding product from an outstanding producer. One last but very important comment. I have no personal or financial interest in Steve’s Detector Rods. I never met the young man and since he lives in Norman OK, probably never will since OK is a mite far from my Florida beaches! Specifications: Upper Shaft Length: 34 7/8 in. Upper Shaft Weight: 4.81 oz. (136 g) Lower Rod Length: 26 in. (custom lengths available upon request) Lower Rod Weight: 3.06 oz. (87g) Material: Carbon-fiber (3K, twill pattern, glossy finish) Cam Lock material: Injection-molded Plastic (nylon) Threaded End Cap material: Delrin Threaded Butt-End Insert material: Delrin

-

Curious if anyone has tried one of these variations on the telescopic rod for the EQX? Says the mount for control pod is from a mold rather the 3-d printed. There are 2 listings, one in UK and the other from a seller in Georgia. https://rover.ebay.com/rover/0/0/0?mpre=https%3A%2F%2Fwww.ebay.com%2Fulk%2Fitm%2F293119857629

-

Hi all!I wanted to mention several things that may be of interest.First of all, as some know, I've been working on making colored shafts available regularly, as a "special order" item. I recently ordered a "test batch" of colored tubes, and all of the colored shafts produced from these tubes have been sold, except one -- it's in the "red/black" color, and I will post a picture of it a bit later.Second, I have several customers requesting colored shafts, so I'm looking to put together a new order for colored tubes from my supplier, in the next week to 10 days or so. I would like to get as many customers as are interested, to let me know, as my supplier would like as a large of an order as possible. So, IF YOU ARE INTERESTED IN A COLORED SHAFT, please let me know. Here is a picture of the available colors...Finally, I just received parts that will allow me to re-stock inventory on the standard (black) Equinox complete shafts; I also have CTX 3030 lower rods, and Equinox lower rods, available as well. Please let me know if you are interested -- sending me an email is the best way to get in touch, at steve@stevesdetectorrods.com.THANKS!Steve

-

Just by coincidence, this 25mm * 23mm carbon fiber tube fits both models, so it's a "win win". I needed a 1" * 7/8" tubing clamp to make the conversion complete. I didn't want to drill a bunch of holes and not have them line up, so I used the "GM 1000 clamp on" cuff. As you can see, I trimmed off about 4" of the mid EQX section. I wrapped sand paper around the cf tube and slowly increased the clearance in the handle/clamp combo, until I was happy with the fit. Total un-extended length is 25", and could be less if you remove the coil. As for the counter-balance weights, it's just another happy coincidence. The washers fit like a glove (.90"), and by adding an over-sized washer, I can move the weight in or out of the shaft. That 1.5" bolt with 14 washers weighs about 4 ounces, and is infinitely adjustable with regards to length, weight, and positioning. https://www.amazon.com/Carbon-Fiber-Tube-Wrapped-Surface/dp/B07DH8WYQQ/ref=sr_1_1_sspa?keywords=carbon+fiber+tube&qid=1554147132&s=gateway&sr=8-1-spons&psc=1 https://www.ebay.com/i/123165031900?rt=nc&var=423574663558&_trkparms=aid%3D222007%26algo%3DSIM.MBE%26ao%3D2%26asc%3D20160908110712%26meid%3Dae995979ba42462ea30ceb0bda2fd5d5%26pid%3D100677%26rk%3D2%26rkt%3D9%26sd%3D122309026322%26itm%3D423574663558 Happy swinging. Brett

-

I have had a 600 for over a year now. There is much to like about the detector; however, the ergonomics are something of a problem. Unlike all my other detectors, I must use the Equinox arm strap, otherwise my arm will not stay within the arm cuff while swinging the detector. My original plan was to try to turn the middle rod into an S rod. I wasn't sure I could do this with just bending, or, if it would be smarter to attach a separate S section either mechanically, via welding, or even via epoxy. Since then, I have acquired two additional middle rods, one for each coil. This would now mean three times the work if I alter the middle rod. The other day I was looking at my AKA Signum MFD. It has the older style plastic housing. Rather than being a straight rod, or an S rod, it is more of a V setup. This got me thinking that if I bend the upper rod of the Equinox so that the arm cuff is higher, (similar to a hockey stick) this may solve the ergonomic problem, or, at least let me get rid of the arm strap. Has anyone tried bending their Equinox shaft? Will a simple conduit bender be sufficient to do the job?

-

Hi all! I just wanted to let everyone know that I have finally been able to kick into shaft production mode, after the last of the long-awaited parts shipment arrived last Wednesday. Shaft building has been underway since, and I'm happy to say that I've managed to start shipping a first handful of shafts to customers on the wait list. Everyone who has contacted me in the past, and had their name added to the wait list requesting a shaft from the "first batch," has been contacted; each of these customers' shafts are compete -- and are now in the midst of a few days worth of epoxy-cure time. I expect all customers on the wait list, who requested a shaft from the first batch and have been contacted within the past week, will have their shafts ready to ship by Wendesday or Thursday. MEANWHILE, I have more than enough parts to build a couple of dozen shafts beyond those allocated to customers currently on my wait list. So, if you are interested in purchasing a shaft, please contact me, or be on the lookout for a "for sale" ad in the classified forum later this week. Finally, I have typed up a couple of detailed documents as well -- one providing lots of information on the counterweights (including assistance/advice on how to choose the "right" length/weight for your personal needs), and then a second document discussing the "spring button hole" option that is being offered, for those who feel they may wish to still utilize the spring button in the lower shaft. Please contact me if you would like to receive either or both of these two documents, or if you have any other questions regarding the new, complete carbon-fiber shafts now available for your Minelab Equinox! THANKS! Steve www.stevesdetectorrods.com (see the "what's new" section for complete shaft information) www.facebook.com/stevesdetectorrods

-

Hi all. Now that I have the prototype shafts built, I've been able to work some more on the counterweight design, and I have moved very close to finalizing the design. I have discovered through this extensive testing/design that the amount of weight needed to achieve proper counterbalance is a bit more than I was originally thinking, after the preliminary, "rough" proof-of-concept testing. I would like to present the findings, and get some opinions -- from anyone who has been potentially interested in the counterbalance system -- as to whether these changes are acceptable, or if this would change your desire to possibly purchase the counterweights. 1. The weight needed to counterbalance the 12" x 15" coil, (based on an "average" lower rod extension length), is roughly 28 oz. This is a fairly substantial amount of weight -- BUT -- I must note that when the weight is applied, the machine swings BEAUTIFULLY. It FEELS lighter, even though the "absolute weight" -- i.e. according to measurement as provided by a scale -- is obviously greater. With my forearm in the arm in the arm cuff, swinging the machine normally, I was literally able to hold the handle of the machine with only my thumb and index finger -- and swing the machine effortlessly! The sensation is that the machine FLOATS across the ground! (For the 11" coil, the amount of counterweight needed is of course slightly less -- roughly 25 oz.) 2. To include this amount of weight in the tube extensions, and yet not have the extensions excessively long, I must use larger-diameter carbon-fiber tube than I planned -- I've decided on 31mm outside diameter tubes. I had intended to use the same diameter of tubing as used on the upper shaft (22.15mm outside diameter), but the extension length required was far too long. 3. Using the 31mm outside diameter tube for the counterweights, I calculate that length of the tube extending beyond the end of the shaft will be 7 1/2" for the 12" x 15" coil, and 6 1/2" for the 11" coil. 4. There would be no changes to the shaft design needed; anyone wanting the counterweight system in the future would still purchase a shaft with the same threaded female fitting installed in the butt end of the shaft, and the same threaded end cap that screws into the butt end. The only changes would be to the counterweights themselves (as comparted to what I had originally planned) -- i.e. larger diameter carbon-fiber tubing, and thus a larger end cap for the ends of the counterweights themselves. SO, my questions are, with the counterweight lengths needed now a pretty-well "known quantity" -- i.e. 6 1/2" and 7 1/2" long (11" coil and 12" x 15" coil, respectively), and the weights to achieve balance being also a pretty-well "known quantity" -- i.e. 25 oz. and 28 oz., respectively, would those interested in the weights find these specs acceptable? Please offer your comments. Preliminary/rough pricing info would be as follows. One counterweight, $22.50 plus shipping ($30 total). If an EQX user only wanted to order one weight, I would suggest the 6 1/2" long, 25 oz. weight, designed for the 11" coil; this amount of counterweight still achieves a degree of balance that feels GREAT with the 12" x 15" coil. I am of the opinion that no counterweight is needed, for the 6" coil. Two counterweights, one for the 11" coil and one for the 12" x 15" coil, $42.50 plus shipping ($50 total). Thoughts? Steve

.thumb.jpg.7d800b44d92cc25158c5722cbce40f62.jpg)