-

Posts

19,751 -

Joined

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by Steve Herschbach

-

From Garrett AT Gold Owner's Manual, page 24: "While in ALL METAL Mode, the AT Gold will respond to the entire range of conductive and magnetic properties encountered, including ground responses. The user is continuously hearing what the searchcoil is "seeing" in the ground. Therefore, it is essential to be properly ground balanced while operating in the ALL METAL Mode. Naturally occurring minerals in the soil must be canceled out during the ground balance procedure in order to detect only the signals from metal objects in the ground. The ALL METAL Mode provides complete target information, including a Target ID pixel on the upper scale, Digital Target ID, and depth reading. The AT Gold thus allows the operator to remain in the ALL METAL Mode at all times, in contrast to some detectors which require the operator to switch to a Discrimination mode to obtain Target ID. Be aware that some deeper targets (faint audible signals) may exceed the reach of Target ID. Because the ALL METAL Mode permits no discrimination, the detector will give an audible signal to indicate every piece of metal it scans over. Target responses will normally be heard as a proportional Medium Tone. However, the AT Gold is a unique All Metal detector in that its Iron Discrimination and Iron Audio™ features can be used to hear if detected targets are ferrous, as indicated by a low tone. Iron Discrimination levels can only be adjusted in the ALL METAL Mode if the Iron Audio feature is on and these changes will not be retained when the detector is switched off. (See Iron Audio section, pages 30–35.)" Page 35: "Iron Audio Use in ALL METAL Mode: In the ALL METAL Mode, all metallic targets encountered by the AT Gold are normally identified by a Medium Tone. The use of the Iron Audio feature, however, allows the introduction of a Low-Tone response to audibly indicate the ferrous content of targets. This Iron Audio feature in a True All Metal Mode metal detector is a Garrett exclusive! The Iron Audio feature should be used in the All Metal Mode as a means to check targets for iron content. Therefore, it is not recommended to hunt with the Iron Audio feature continually switched on. To fully appreciate All Metal Iron Audio, use an iron nail and a coin to experiment. Select the ALL METAL Mode, temporarily switch on Iron Audio, and set the IRON DISC to 35. (Note: Iron Audio must be switched on in order to set Iron Discrimination in the ALL METAL Mode.) Switch Iron Audio back off and pass the nail over the searchcoil. The nail will respond with a clean Medium Tone, similar to that of a good target, such as the coin. Now, switch on Iron Audio and separately pass the two targets completely over the coil again. The distinctive Low-Medium-Low response of the nail now indicates a target that is unmistakably iron. Note that the coin, however, continues to respond with a clean Medium Tone." The AT Gold function above is a type of mixed mode, layering a disc channel response over the all metal channel. As usual the ferrous indications do not reach as deep as the all metal channel. The Minelab X-Terra 705 has a similar function in the all metal Prospect Mode which Minelab calls Iron Mask. However, instead of producing a tone the Iron Mask function causes the audio to break up or blank completely on ferrous targets. The Iron Mask setting is adjustable. Lower settings will call more ferrous items good but at less risk of accidentally calling a gold nugget ferrous. Increasing the setting rejects more ferrous items but increases the chance a non-ferrous item will be incorrectly rejected. The XP Deus Gold Field program has their own version of Iron Mask called Iron Amplitude Rejection (IAR). From the XP Owner's manual, page 9: "The program No 10 GOLD FIELD uses another discrimination method, called IAR (Iron Amplitude Rejection): the range of discrimination can be applied from 0 to 5. It applies only to targets that produce strong signals – typically shallow ferrous items. It will not reject deeper targets which may come across as ferrous when they are buried in mineralised ground, to ensure good targets are not rejected by mistake. Higher discrimination values, enable the detector to reject deeper ferrous. Gold nuggets buried deep in mineralised ground can generate a similar signal to a ferrous item, so in this case it is better to reduce the level of discrimination." All White's Goldmasters have an "Iron Grunt" feature that operates at a relatively safe level of "bias" and gives a broken low tone on ferrous targets while in all metal mode. The GMT refined this by adding a "Probability Meter" that is an early version of the "Confidence Meter" seen on some other models these days. From White's GMT Owner's Manual, page 12: "Iron I.D."GRUNT" ON - IRON I.D. information is obtained by using the trigger switch under the display pod. Locking the trigger forward adds sound to the IRON I.D. system. Now when the search coil passes over an iron target, a "GRUNT" sound is added at the tail end of the normal metal target zip-zip sound. The alert "GRUNT" is triggered when the % probability of the target being IRON reaches 85% to 95%. The trigger locked forward for audio alert does not change any function of the system, it just adds sound. ALL targets will be heard with NO LOSS OF DEPTH. Trigger Squeezed - Iron I.D."GRUNT" ON - While the trigger is squeezed, the GMT IRON I.D. system performs a very unique function. Normal tracking STOPS and IRON I.D. adds each successive pass to its memory bank. Unique to the GMT, we call this feature "TARGET ANALYSIS". Since tracking stops during this process with the trigger squeezed, this analyzer cannot be utilized while searching. It is only used to"TEST" a suspected IRON target. It is also important to make long enough passes over the target to include the ground in the search field. This allows the detector soft ware to perform an accurate analysis. The sweep should be wide enough for the coil to completely leave the target. 1 1/2 to 2 feet is adequate for a small shallow target, wider for deeper, larger targets. This is DIFFERENT from most other metal detectors you may be accustomed to, which use a conventional discriminator to attempt to identify iron. The main thing is not to hover or dawdle over a target while analyzing. As with the "locked forward position", the "squeezed" position also functions while in MANUAL Ground Balance. NOTE* THE VISUAL IRON I.D. SYSTEM IS OPERATING IN ALL THREE TRIGGER POSITIONS. The % of Iron Probability is indicated on the display by a left to right bar graph. This system is totally independent of the Audio Alert System." The White's MXT offers the same Probability Meter and Iron Grunt features as the GMT when operated in its Prospecting Mode. There is a benefit in that the MXT is running at 14 khz instead of the 48-50 kHz of the Goldmaster/GMT models, making this a potentially more useful mixed mode function for general coin and jewelry detecting. The GMT runs too hot for many general detecting purposes. While the MXT is operating in the Prospecting Mode, iron targets 80% and over produce an audio grunt when detected. The new White's MX Sport shares many features with the earlier MXT models including the Iron Grunt while in all metal mode. From the MX Sport Owners Manual, Page 26: "Iron Grunt - In the All Metal modes, when the MX Sport is sure the target is iron, the iron grunt feature can speed detection by making it obvious the metal is iron. Strong IRON type responses are assigned a distinctive “GRUNT” sound. To turn on Iron Grunt: Assure you are in an all-metal program: All Metal, Relic, or Prospecting. Press Options and select Iron Grunt with the up and down arrows. Use + and - to select 1 = Iron Grunt, or 0 = OFF (no iron grunt)."

-

There is the MXT with the Relic mode plus the Prospect mode iron grunt feature. There are others, like the XLT, DFX, VX3, and the V3i you mentioned, the latest being the Nokta Impact. The Nautilus is the granddaddy of mixed mode units. What you are referring to is an audio mixed mode where the disc and all metal channels run simultaneously. Unfortunately the disc portion of the signal does not reach as deep as the all metal portion of the signal. In theory Fisher could divert the F75 metered response while in all metal to a secondary audio channel to create an audio mixed mode. Especially since Dave Johnson was a key engineer on both the MXT and F75 - he clearly knows how to do it. I suspect the reason it has not happened is very few people know what a mixed audio mode is and fewer yet are asking for it as a feature in new machines. Many people consider mixed mode operation to be too "busy" for general use, especially in trashy locations. It is difficult to get the audio right for more than specific site hunting or places where targets are quite sparse. From the White's DFX Owners Manual, Page 21: "Mixed Mode - A unique hybrid operating mode. It is an all-metal (DC non-motion, non-discriminate) mode, working simultaneously with a discriminate (AC motion discrimination) mode. It is two modes, one detecting everything and another discriminating, operating at the same time. Discrimination Channel - When the loop is in motion, targets accepted by the discriminate program will produce a high-pitched beep. Targets rejected by the discriminate program will produce a lower pitched beep. High-pitched or low-pitched beeps are directly determined by the discrimination settings. An operator can select discriminate settings through the selection of an entire Program or by adjusting the accept and reject V.D.I. numbers in the Pro Options under Discrimination (EDIT). All-Metal Channel -When the loop is not in motion, or moved slowly, all types of targets will produce the same low-pitch beep. All-metal channel will by nature detect deeper than the discrimination channel. Deeper targets will produce a lower volume sound when the loop is moved slowly over the area. Tip - Advanced operators can gain extra depth by monitoring the all-metal and discriminate channels simultaneously, checking depth and digging targets too deep for the discriminate channel alone. For even more information about the target, Pro Options TONE I.D. and or V.C.O. can be added to produce a truly unique advanced users mode." That last tip is a big one! For mixed mode, it is often the targets beyond disc range that deserve the most interest. You use the disc channel to pass on shallower targets and go after those unknown but very deep targets. The assumption is the deepest stuff is most likely to be great finds passed over by others using standard discrimination. What we all are really wanting however is the full depth of a true all metal mode that discriminates to that full depth. The problem in getting there is simple. A true all metal channel only needs to tell you there is a target down there. This requires only the most minimal signal - a bare bump or break in the threshold is all it takes. A discrimination channel has to have enough phase information to make a discrimination determination. This requires a stronger signal. Any amount of detecting in bad ground will tell you target id accuracy declines with depth as the ratio of target signal to ground signal mix degrades. The deeper the target, the harder it is for the filtering circuit to tell what is target and what is ground. Eventually you get to where you know something is down there but the signal has degraded so much you/the detector can't tell what it is. It will always be easier for a detector to say "there is something down there" then it will be for a detector to identify what that something is with any degree of accuracy. This is the reason why prospectors have for many years been digging targets at depths not seen by people who need to use detectors that have some sort of discrimination capability. Ultimately all that matters in prospecting is pure power, pure depth, and that is what the machines deliver. Discrimination always robs depth, and is frighteningly inaccurate at fringe depths, causing good finds to be dismissed as trash on a regular basis. That is not to say we have not got machines that have been getting better discrimination at better depth. The F75 and CTX 3030 push accurate discrimination at depth about as far as it can currently be pushed. There will be improvements in the next few years as new technology comes on line. I never see the day coming however where we will get even just accurate ferrous/non-ferrous discrimination to the same depth that we can get basic target notification due to the fact that the one thing requires more signal definition than the other thing. A mixed mode scheme is as close to that as I think we will get. The closest thing right now to what you are asking for is probably the Nokta Impact Gen (D) mode. The Impact is neck and neck with the F75 for overall performance but with additional features the F75 lacks, such as mixed mode. Whether it can equal or exceed the F75 in your particular ground I unfortunately can't tell you. Excerpt from the Nokta Impact manual below. Gen basically allows you to run the Impact as if it is an F75 in all metal mode by setting the disc at 0. Then as you increase the disc setting, you get a iron tone for items at or below the setting you have chosen. Gen (D) is factory preset for ferrous/non-ferrous tones. The give-away that it is a mixed mode is that you get the same tone for targets at fringe depth and discrimination effects at less than fringe depths. Adapted from the Nokta Impact Owner's Manual, page 13: GEN - General Search Different than the other modes, this mode features a threshold tone which is continuously heard in the background. General Search (GEN) mode is used in 2 different ways in the IMPACT: 1) with the Disc. setting disabled at 0 2) with Disc. enabled (non-zero). When the device is first turned on, Disc. setting will be off. When the Disc. is set at 0, the device does not discriminate targets and detects all targets (metals, mineralized rocks etc.). ID of the detected target is shown on the display (except for negative hot rocks) and the same audio tone is provided for all targets. The audio tone increases in pitch as the coil approaches the target. This is the typical All Metal mode found in most detectors. When using the Disc. Setting in this mode, the device will emit a low ferrous tone for all targets below the Disc. Setting, and a higher tone for all targets above the Disc. setting which changes in pitch as the coil approaches the target. Let's say you set the Disc. to 20. The device will generate a low iron tone for all metals with 0-20 ID and a higher tone for all targets with 21-99 ID. Upon target detection, the threshold will momentarily go silent and only the target audio response will be heard. The duration of the threshold's silence is directly related to the level of the iSAT. Gain, threshold and iSAT settings in this mode are optimized to provide the best performance on different terrains. You can modify these settings based on ground conditions. We recommend using the GEN mode when more detailed discrimination is not important and not using it in heavy trash areas or areas containing many hot rocks. GEN (D) - General Search Delta In principle, it works the same as GEN mode. The difference is that the GEN (D) mode will generate the same tone for ferrous and non-ferrous targets at fringe depths but it will discriminate the shallow ferrous targets by emitting a low iron tone.

-

Unfortunately this bloke is not an experienced prospector. However, it is the first report I have seen by anyone using the new V4 high frequency coil to look for gold nuggets. That alone made it of interest to me. http://aussiedetectorist.com.au/2017/04/05/xp-deus-version-4-in-the-australian-goldfields-can-the-deus-find-gold/

-

A Nice Specimen But You Can`t Tell By Looking At It

Steve Herschbach replied to phoenix's topic in Detector Prospector Forum

Nice find! The SDC does indeed still have an edge on some small and specimen gold due to the smaller coil. That edge should disappear once a small coil is available for the GPZ although because of the differences between the way the two machines function the SDC may continue to have some advantage in extreme mineral ground. -

Detector Floodgates Open In May

Steve Herschbach replied to Steve Herschbach's topic in Metal Detector Advice & Comparisons

In general the people most willing to talk are the ones least likely to know. The people who do know are bound by non-disclosure agreements and are not going to say squat. Short of having one in your hands it seems to me nearly every possible fact about the GM1000 is already known. -

Tone By TID Selection Option?

Steve Herschbach replied to GB_Amateur's topic in Metal Detector Advice & Comparisons

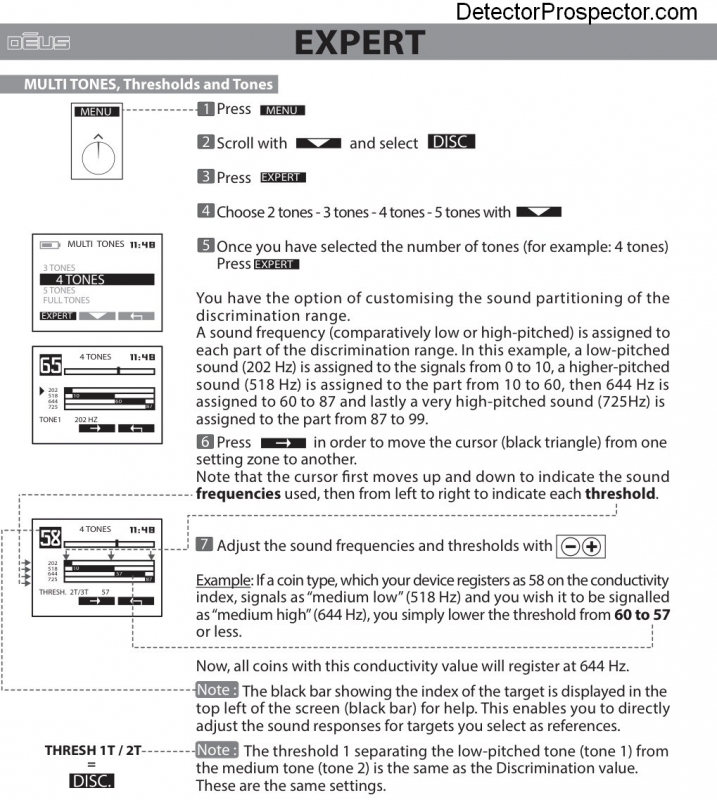

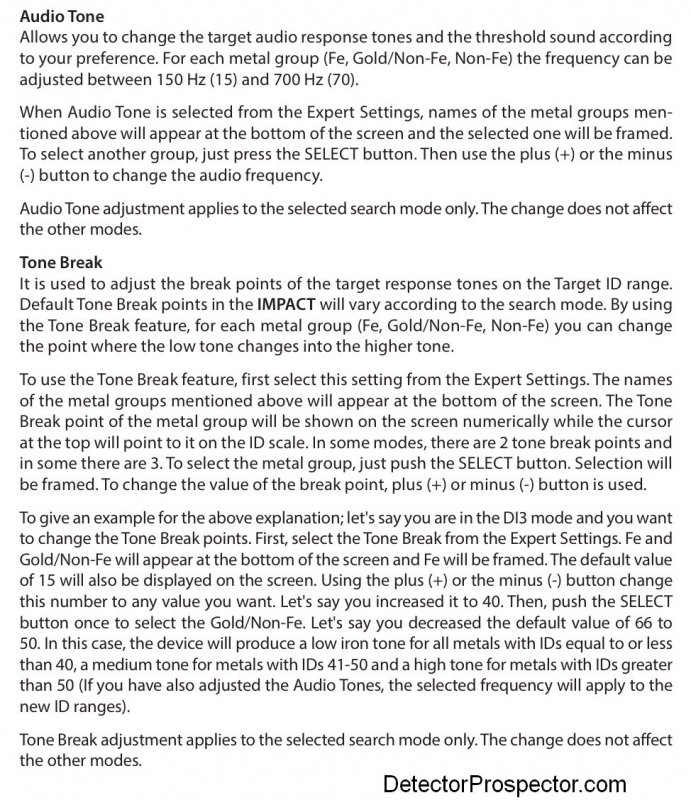

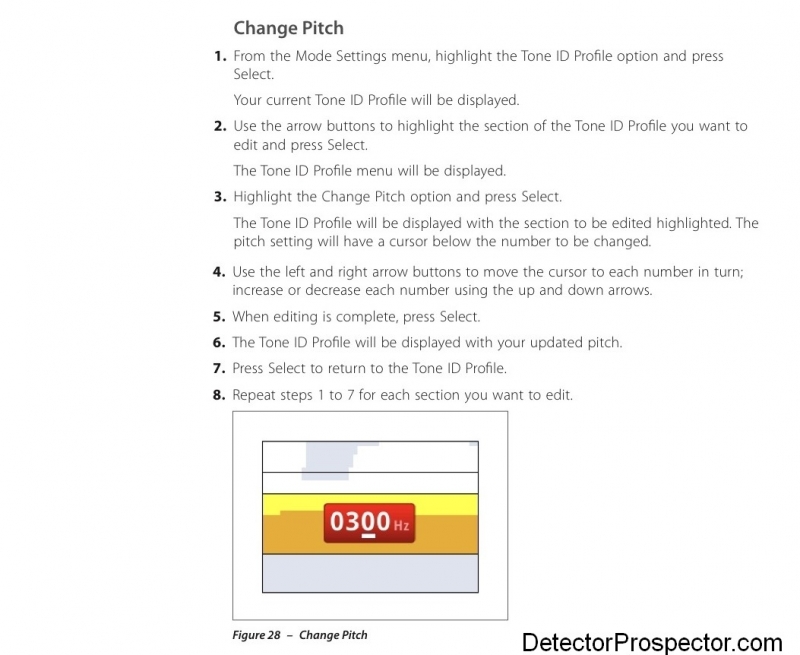

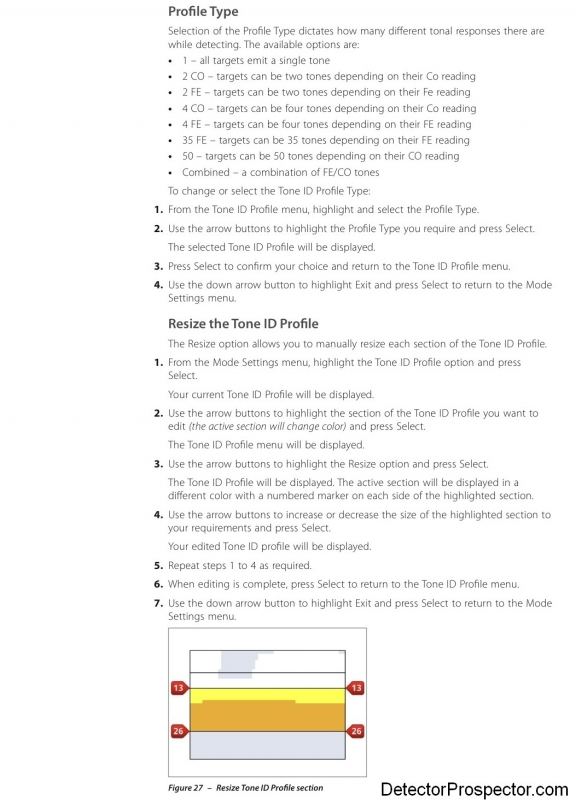

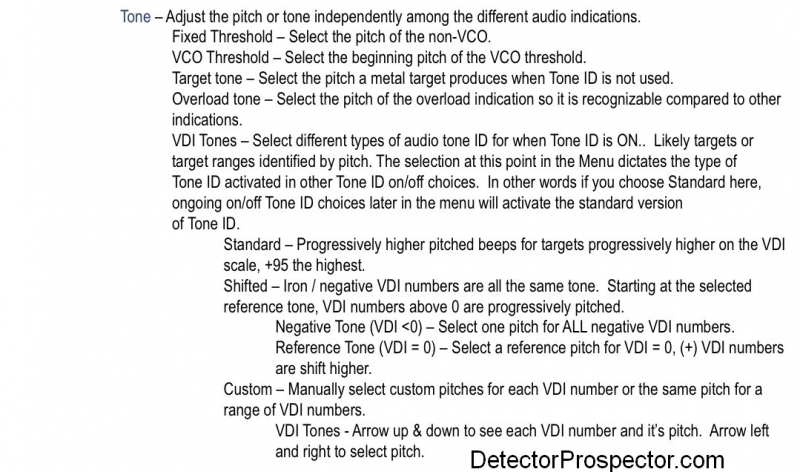

Most tone id machines have preset tone ranges but only a few allow you to customize the tones. Minelab calls those "bands" of TID numbers "bins" as in a bin full of numbers. The CTX 3030 will allow you to set custom bin ranges and tones. The Makro Racer 2, Nokta Impact, and XP DEUS have similar capability. The Whites V3i is the ultimate in allowing tone selection by individual TID number. I am sure there are others but these are just current models off the top of my head. XP DEUS Nokta Impact (and Makro Racer 2) Minelab CTX 3030 White's V3i -

We have the New Garrett AT Pro 2? coming in May. The new Minelab Gold Monster 1000 is said to be available in May. The new Nokta Impact is now shipping to dealers and will have widespread availability in May. And finally, the new XP DEUS HF elliptical coil is supposed to ship in May! Looks like something for just about everyone there. Not sure about the Garrett but look for more from me on the Minelab GM1000, the Nokta Impact with large coil, and the Deus elliptical coil when the time comes.

-

The New Garrett Is Finally Coming!

Steve Herschbach replied to Steve Herschbach's topic in Garrett Metal Detectors

Nobody will know what it is until they announce it. Garrett is quite secretive. However, most bets, including mine, are that it will be the AT Pro 2. The AT Pro is a hugely successful detector but due for an update to keep it fresh. Garrett has already announced the new machine will have built in wireless headphone capability. Add a few more tweaks like a larger display and maybe a backlight, and you have a "new" detector. -

I use the 13.5" x 17" more for ground coverage than depth. I like the 17" personally and maybe it's just from swinging a GPZ so much but the weight does not bother me. My 17" weighs 901.5 grams / 31.8 oz on my postal scale including cable versus the 985g / 34.7 oz reported for this new coil.

-

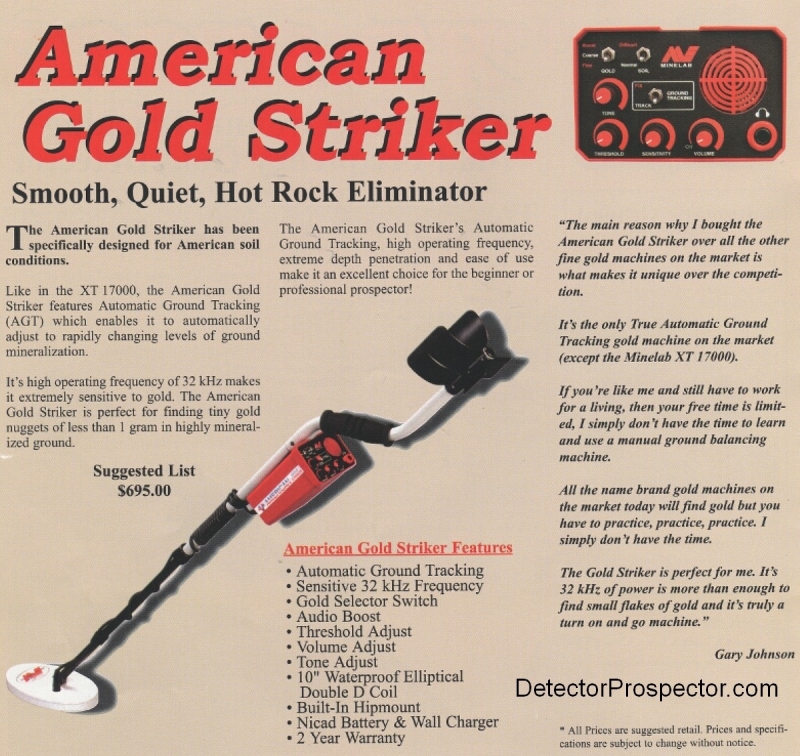

I had a Minelab American Gold Striker briefly after my XT 17000. I took it back to areas where I had hunted before with the XT 17000 with lackluster results. Not a bad unit it just did nothing to up the ante. As the name says, the "American" was aimed specifically at the U.S. market. It came out in 1994 and at a dedicated 32 kHz (and lower price than XT 17000) was an attempt to respond to the recently released 50 kHz White's Goldmaster models. The problem was that at 50 kHz the Goldmasters slayed the Gold Striker on the small stuff and at $695 the Minelab unit was priced $200 over the White's Goldmaster II. The main thing Minelab pushed was that the Gold Striker had automatic ground tracking which the White's units lacked. I sold truck loads of Goldmasters and after a short try did not even bother stocking the Gold Striker. Gold Striker Owner's Manual Click images below for larger versions...

-

The New Garrett Is Finally Coming!

Steve Herschbach replied to Steve Herschbach's topic in Garrett Metal Detectors

-

First Gold And Silver With The CTX

Steve Herschbach replied to Rivers rat's topic in Metal Detecting For Jewelry

Glad you finally scored with the CTX. I do like the 17" myself for beach work in particular. It really helps when faced with huge areas to cover. -

Gem Stones Of The United States

Steve Herschbach replied to Steve Herschbach's topic in Rocks, Minerals, Gems & Geology

From 1957 so a little bit dated, but a good introductory text. -

A CONTRIBUTION TO ECONOMIC GEOLOGY (1957) GEM STONES OF THE UNITED STATES By Dorothy M. Schlegel ABSTRACT Many semiprecious, but few precious, gem stones have been found in the United States. Beauty, durability, and rarity are the most important qualities of a precious gem. Gem stones are distinguished by their physical properties: color, crystal form, cleavage, parting, hardness, specific gravity, luster, index of refraction, transparency, and dispersion. Gems are named for their color, type locality, outstanding physical property, or persons. The most popular gem cuts are the cabochon, rose, brilliant, step, and mixed. The carat, one-fifth of a gram or 200 milligrams, is the unit of weight measurement. The color of four popular gems may be changed by heat treatment or dyeing. Only the ruby, sapphire, spinel, emerald, rutile, and quartz of gem quality have been synthesized. The best quality of assembled stones are the doublet and triplet. Most gem stones are found in alluvial gravels and igneous rocks, especially granite and pegmatite deposits. INTRODUCTION Gem stones generally are divided into two categories: precious and semiprecious. A precious gem stone has beauty, durability, and rarity, whereas a semiprecious gem stone has only one or two of these qualities. The diamond, emerald, ruby, and sapphire are considered precious gems. Some opal is precious, but most varieties are semiprecious. The beauty of a gem stone is determined by personal taste. In ancient times man preferred brightly colored, translucent or opaque stones. Today he prefers evenly tinted, transparent stones. The desired hues are blue, rose, green, and true canary yellow in the diamond; pigeon-blood red in the ruby; cornflower blue in the sapphire; and grass green in the emerald. Most diamonds, however, are colorless. The durability of a gem stone depends upon its hardness and lack of ready cleavage. A gem must be sufficiently hard to resist abrasion by objects normally found in everyday life and by dust. It should also resist the chemicals with which it comes in contact. Cleavability is the tendency of certain gems to split in one direction more readily than in another. Rarity is one of the most important factors in establishing the price of a gem stone. Such gems as the diamond and ruby are rare, in addition to being beautiful and durable, and therefore are very expensive. Although the deep red pyrope garnet closely resembles the ruby in color, there is no comparison in expense and popularity. The purpose of this report is to give the amateur gemmologist some of the important information available on the gem stones of the United States. Although the finest precious gems occur in foreign countries, a wide variety of semiprecious stones, and a few precious gems, have been found in the United States. About 50 major gems and the geology of their occurrence are described in this report. William F. Foshag, U. S. National Museum, has kindly reviewed the manuscript and made many valuable suggestions. Dana's "A textbook of mineralogy" is the source of the chemical formulas. Full text PDF here

-

Not much in the way of new information but Trevor Ferraresso of Coiltek has posted a new Treasure Talk blog about the new CTX 9" x 14" coil. The coil is supposed to be available for purchase now according to the article.

-

What Was Your 1st Detector?

Steve Herschbach replied to Sourdough Scott's topic in Metal Detector Advice & Comparisons

1972 White's Coinmaster IV T/R, just before disc was invented. No ground balance either. Still found a lot of silver with that detector though because there was lots of silver to find back then! I have a list on my profile of 84 detectors I have used and I know I have forgot a few. Owning a detector shop it was just part of the gig for me for many years and old habits die hard. -

How To Load Claim Maps Onto Garmin Gps?

Steve Herschbach replied to Jakepilot86's topic in Rocks, Minerals, Gems & Geology

From http://www8.garmin.com/outdoor/custommaps_instruct.pdf Create Your Own Garmin Custom Map Before downloading your custom map, you must install the latest software for your device. Visit http://my.garmin.com for more information. When creating your custom map, be responsible and only create a custom map from a map that is in the public domain, that you hold the copyright in, or that you have permission to use from the copyright holder. To discuss custom maps with others, please visit our Garmin Custom Maps developer forums. More GPS Map Tutorials Here Garmin Compatible Custom Maps Available Here. -

History Of Placer Mining In Nevada

Steve Herschbach replied to Steve Herschbach's topic in Rocks, Minerals, Gems & Geology

That Nevada has no water would be a misperception on your part Tom. I live in Reno and we have a beautiful river running through the middle of the town. The Manhattan dredge was a very large floating bucket line dredge. There is an excellent picture of it at http://yankee-nevadan.weebly.com/manhattan-nevada.html http://www.kecnv.com/InterpretiveWorks/ManhattanGulchMarker.pdf http://www.kecnv.com/InterpretiveWorks/DredgeFlipBook/files/mobile/index.html#1 -

Sourdough Scotts' Notice To Appear

Steve Herschbach replied to klunker's topic in Detector Prospector Forum

You guys really should not drink that stuff! -

Mystery Backpack Dredge

Steve Herschbach replied to EZMoney Bob's topic in Gold Panning, Sluicing, Dredging, Drywashing, Etc

The Petco was later and is basically just a cheapie chainsaw motor. Did not hang around long in the Keene lineup before getting replaced by better motors. -

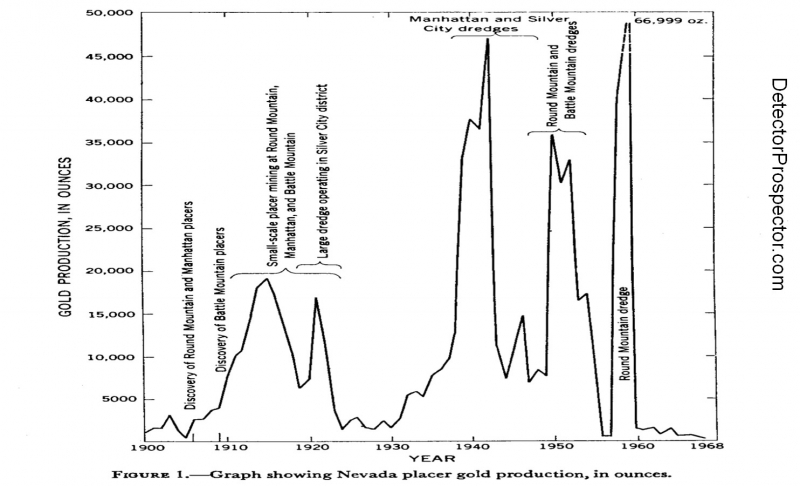

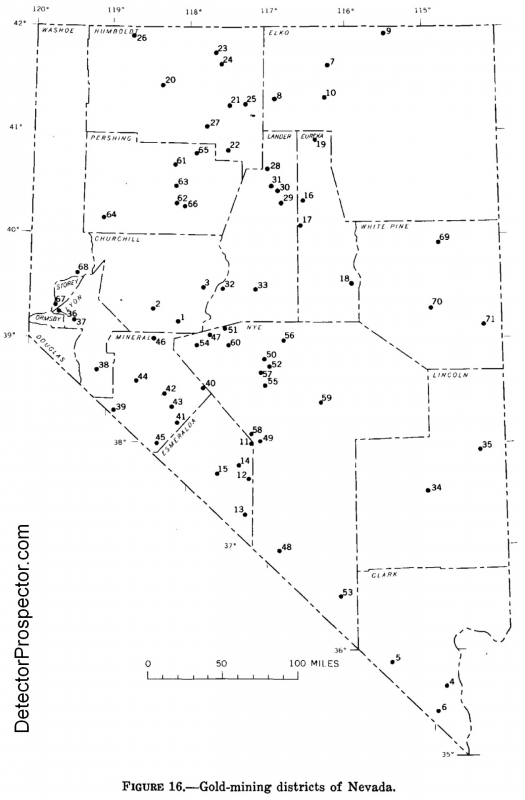

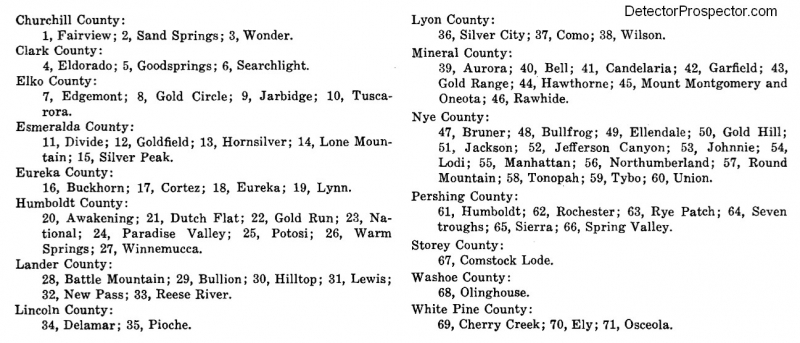

From Placer Gold Deposits of Nevada, USGS Bulletin 1356, By Maureen G. Johnson 1973 HISTORY OF PLACER MINING IN NEVADA The first authenticated discovery of placer gold in Nevada was made in 1849 by Abner Blackburn, a member of an emigrant train to California, at the junction of Gold Canyon and the Carson River at the present site of Dayton, Lyon County (De Quille, 1891; Vanderburg, 1936a). Parties of men worked the gravels in Gold Canyon and nearby Six Mile Canyon, Storey County, for 8 years before the source of the placers, the Ophir silver lode, was discovered by Peter O'Reiley and Patrick McLaughlin in 1857 while digging a small water hole for placer mining in Six Mile Canyon (De Quille, 1891). Other lode discoveries in the immediate area followed, and soon the whole world knew of the Comstock lode in Nevada. Although placer mining continued on a small scale in Gold Canyon and Six Mile Canyon, and other placers were discovered elsewhere in the State, the richness and fame of the Comstock lode far overshadowed the importance of placer production and new placer discoveries. Following the discovery of placers at Gold Canyon, placer discoveries in Nevada were broadly in three periods: the 1860's to 1880's, when many small deposits throughout the State were discovered and sporadically worked and several large placers were discovered and extensively worked; the short period between 1906 and 1910, when very rich placers were discovered at Lynn, Battle Mountain, Manhattan, and Round Mountain; the early 1930's, when economic conditions created by the depression caused a renewed interest in placer mining, and many individuals sought, and a few discovered, new placer areas throughout the State. The location of the placers described in this report is shown on plate 1. Very little factual information can be found about the early periods of placer mining in Nevada. For many placers, the only reports available are hearsay estimates of production and speculations about the extent of the placer ground based on remnants of placer pits, shafts, and other workings. Many of the placers said to have had a high production between 1860 and 1890 were worked by Chinese miners who came to Nevada during the building of the railroads and stayed on to work at mining and other activities. The Chinese were reputed to be secretive with their earnings from the placers and did not ship the gold to the mint by Wells Fargo or other shippers. They worked the gravels very thoroughly in areas where American miners did not wish to expend great labor to win the gold. The placers in the Sierra and Spring Valley districts, Pershing County, were worked by Chinese miners; they have a very high estimated production before 1900 and a comparatively low known production since that time. One reason for the lack of information about early placer-mining activity in Nevada was the great attention given to the rich silver-lode districts such as the Comstock, Eureka, and Reese River districts. Whereas in many other States, the discovery of gold placers stimulated the search for lode-gold deposits and other gold placers, in Nevada early attention was devoted to searching for rich silver lodes not necessarily associated with derived placers. The comparatively late discovery of some of the richest placers in the State has afforded a very clear picture of the development of placer mining during the 1900's. The discovery of rich silver ores at Tonopah in 1900 and rich gold ores at Goldfield in 1902 stimulated great activity in mining exploration throughout Nevada. Many placers discovered during the 1906–10 period were found by men looking for ores similar to ores at Tonopah and Goldfield. Placer mining at Manhattan and Round Mountain districts, Nye County, and Battle Mountain district, Lander County, began with numerous small drywash operations in the gravels, then expanded as water supplies were developed for sluicing and hydraulic methods of mining. Late in the history of these districts, but long after many other placer districts were inactive, large-scale dredging operations began. The success of the dredge operations in these semiarid districts is unique in the history of placer mining in the Southwestern States. Placer mining history in the other districts is typical of desert placer mining throughout the southwest. Most production resulted from the relatively intense period of prospecting immediately following discovery; a decline in placer-mining activity followed, then a small revival during the early 1930's. The economic depression of the early 1930's stimulated investigations of many Nevada placer districts for the purpose of developing large-scale placer-mining operations. By the late 1930's, many mining companies had investigated many placer areas and had formulated plans to develop certain areas. The placer activity of the 1930's was abruptly halted by the beginning of World War II and the passage of War Board Order L–208, which restricted gold mining throughout the country. The dredge operation at Manhattan was given special permission to continue operations, although on a reduced scale, and, as a result, placer gold production after 1942 did not decline as markedly in Nevada as in other States. Most of the placer mining was done by the basic methods of drywashing, sluicing, and rarely, small-scale hydraulic mining. In addition to the large dredge operations at Manhattan, Round Mountain, and Battle Mountain, other dredges operated in different districts, notably Silver City, Lyon County; Spring Valley, Pershing County; Van Duzer, Elko County; and Bullion, Lander County. Since the completion of the Round Mountain dredge operation in 1959, placer mining in Nevada has progressively diminished in importance. GOLD PRODUCTION FROM PLACER DEPOSITS The U.S. Bureau of Mines (1967, p.15) cites 1,900,000 troy ounces of placer gold produced in Nevada from 1792 to 1964. I estimate a total production of 1, 700,000 ounces of placer gold for the State from the first placer discovery to 1968. The U.S. Bureau of Mines estimate includes some unauthenticated reports of very high placer gold production from some districts worked before 1900. The most productive placer districts in Nevada are the Battle Mountain district, Lander County; Silver City district, Lyon County; Manhattan and Round Mountain districts, Nye County; Spring Valley and Sierra districts, Pershing County; and Osceola district, White Pine County. Most of the gold recovered before 1900, an estimated 905,850 ounces, was recovered by many individuals using drywashers or small sluices to work gravels brought to the surface from shafts or pits. In the major districts (Silver City, Spring Valley, Sierra, and Osceola) worked intensely between 1849 and 1890, the miners dug numerous shafts, tunnels, and adits in the gravels. At Osceola, large banks of gravel were hydraulicked, leaving sheer cliffs of unworked gravels exposed today. After 1900, drywashers, small sluices, and small concentrating machines continued tp be used in placers throughout the State, but, except for the very productive first few years of drywashing at Manhattan, Round Mountain, and Battle Mountain (1906-15), the greatest part of the placer gold was recovered by large dredging operations. Figure 1 is a graphic representation of the total amount of placer gold recovered yearly in Nevada (1900-68) and the contributors to the major production peaks. Dredge mining in Nevada started in 1911, when the Federal Mining Co. used a small wooden dredge to work gravels in Spring Valley Canyon (Pershing County). The operation was only moderately successful, but it encouraged other companies to consider desert dredge mining. During the periods 1920-23, 1940-42, and 1946-47, dredges worked in the relatively well-watered Carson River at Gold Canyon (Dayton, Lyon County). Small dredges worked gravels in a number of districts throughout the State (such as the Bullion district, Lander County; the Willow Creek district, Pershing County; and the Olinghouse district, Washoe County), but in many of these operations, the water was not sufficient for the use of floating dredges, and other conveyances were used to transport the gravels to the dredge, which acted as a central washing plant. The era of major large-scale desert dredge operations began in 1939, when a floating bucketline dredge was brought to Manhattan Gulch (Nye County). When operations ceased in 1946, this same dredge was transported to Battle Mountain (Lander County) to work the placers in the Copper Canyon fan from 1947 to 1955. In the 1950's, a non-floating dredge was used at Round Mountain (Nye County) to recover large amounts of placer gold from a deep pit. Since cessation of dredge operations at Round Mountain in 1959, placer gold production in Nevada has returned to small-scale sporadic or part time operations by individuals. SUMMARY Placer gold has been found in 115 mining districts in Nevada. Many of these districts have produced, or are said to have produced, only a few ounces of placer gold. Thirteen districts have produced more than 10,000 ounces. Although placer gold has been recovered from each of the 17 counties in Nevada, most of the placers are in the western part of the State (see pl. 1) in the area termed the "Western Metallogenic Province," which is characterized by the dominance of precious metal ores (Roberts, 1946a). A few placers (all of minor importance except the Osceola district) are found in the eastern part of the State in the area termed the "Eastern Metallogenic Province," which is characterized by the dominance of base-metal ores. Most of the placer gold found in Nevada has been derived from veins and replacement deposits that have been successfully worked for the gold and silver content of the ores. In the few districts where source of the gold is unknown, it is presumed to be small scattered veins in the adjacent bedrock. In most of the very productive lode mining districts, only small amounts of placer gold have been recovered, whereas in the very productive placer districts, lode-gold production is close to, and sometimes less than, placer gold production. An exception is the Silver City district (Lyon County) , which has yielded a high production of placer gold derived from ores of the Comstock lode (Lyon and Storey Counties), the largest silver producing district in the State.

-

Tesoro Diablo Umax ( Unused )

Steve Herschbach replied to goldrat's topic in Compass, D-Tex, Tesoro, Etc.

Links are way easier! https://www.prospectingaustralia.com.au/forum/viewtopic.php?pid=323804#p323804