-

Posts

214 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by Chet

-

Running The 15" Cc X Coil Over A 6000 Patch

Chet replied to jasong's topic in Minelab Metal Detectors

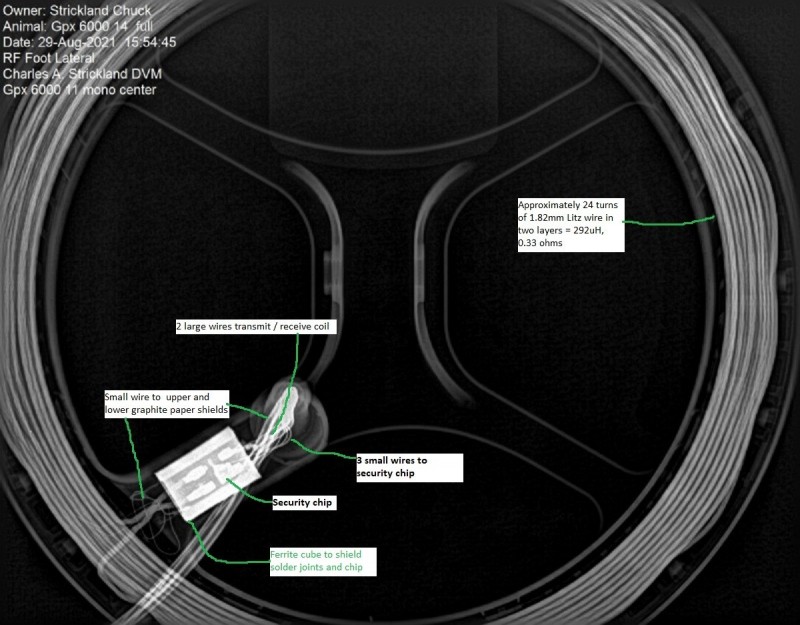

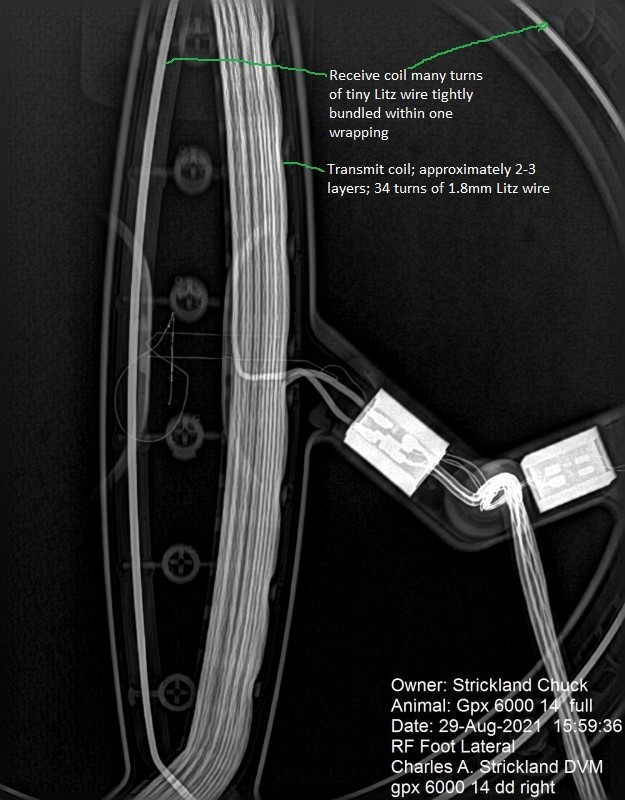

The GPX 6000 11” and 17” x 13” Mono coils have the same electrical specifications as most previous GPX series coils. That is; the inductance is close to 300 microhenrys (uH) and the direct current resistance is close to 0.3-0.5 ohms. And shielding appears to be similar. The GPX 6000 Double D receiver coil is different from previous GPX series Double D coils. I could not get a DC ohms measurement across the receiver coil. It appears to have a capacitor in series with the winding. Small existing GPX aftermarket coils using some type of adapter/dongle will probably work great. The GPX 6000 works great on small shallow gold by having a fast recovery and processing time for short time constant targets. There may be limitations on large deep gold using large existing aftermarket coils. The GPX may be designed with overall power and sensitivity limited near the GPX 5000 performance. Concentric coils could certainly be developed for the GPX 6000. It would require much development and testing of various sizes to hit sweet spots in performance for different nugget sizes and different depths. Concentric coils for the GPX 6000 will need to demonstrate an overall performance improvement or specific niche in the midst of the other coils to make profitable sales. -

Coiltek Coils For The GPX 6000 - Confirmed!

Chet replied to Coiltek's topic in Detector Prospector Forum

My choices for Elliptical coil sizes are; 9” x 6”, 14” x 9”, and 24” x 15”. For Very Low Frequency (VLF) detectors with high length to width ratio elliptical coils such as Big Foot coils work well for coin and relic hunting. In my opinion Pulse Induction (PI) gold detector elliptical coils should have more conservative ratios of less than 1.60 : 1. I think conservative ratios provide a good balance between detecting small shallow nuggets and larger deeper nuggets. If the goal is to detect mostly very small shallow nuggets then higher elliptical ratios of 2:1 or 3:1 in small coil sizes may be desired. Have a good day, Chet -

Tony When detecting in trashy areas, gullies and desert washes I frequently carry a VLF along with the GPX 5000, GPZ 7000 and now with the GPX 6000. If roaming large areas of desert with only an occasional bullet or boot tack to contend with the VLF is left in the Jeep. Over many years as VLF detectors improved the models for this purpose were upgraded from the early Goldmaster series to MXT to GMT to Gold Monster to now to a Equinox 800. All equipped with the smallest coil available. When a target is detected in a trashy area with the Large PI coil it is quickly pinpointed and discriminated with the VLF. If is too deep to detect with the VLF it gets you pumped up a little thinking that this is something good. As the hole gets bigger and deeper the small coil on the VLF pinpoints the direction to dig. Sometimes a dozen plastic knives with bright colored surveyors ribbons tied around them are used as markers. Detect the area with the PI. If a shallow loud target is detected lay a knife over it. If it is a weak low broader signal place the blade into an upright position. Lay the PI down and detect each marked target with the VLF. The shallow loud ones are fast and easy. The deeper ones require some aggressive digging to get the VLF close enough to detect, pinpoint and discriminate. From years of experience with many detectors has led to this determination. The Equinox 800 with the small coil is the best, simplest automatic detector for this work and/or for stand-a-lone gold detecting. It has a build in pinpoint mode that immediately gets you on top of the target. Once on top you punch it back to discriminate mode and one or two sweeps you know whether it is ferrous, nonferrous or a hot rock. The target number read-out is so much better than the Gold Monster bar graph. Like most modern highly sensitive VLFs built for gold detecting it will sound off on many hot rocks. But it will have a repeatable number read-out that will correlate to the normal hot rocks produced in that area. Have a good day, Chet

-

Quick Question For Western Australia Guys

Chet replied to IdahoPeg's topic in Detector Prospector Forum

I spent 6 weeks camping in Canada and Alaska in the summer of 1989. It was a great road trip except for the mosquitoes and flat tires. I did master the Canadian salute; the action of slapping them flat on my forehead. -

All detectors are of little use at 1m depth unless it is that rare multi-ounce retirement nugget. As previously stated you must remove the overburden. Watch Rob’s video on this forum at; https://www.detectorprospector.com/forums/topic/16593-part-2-dig-shovel-rake-metal-detecting-for-gold-nuggets-video/#comments Have a good day, Chet

-

Quick Question For Western Australia Guys

Chet replied to IdahoPeg's topic in Detector Prospector Forum

The camera operators and TV directors are probably wearing them lol. -

The detecting environment has some effect on the choice of coil cable routing and placement. It was like sliced bread was reinvented when the GPZ 7000 came out with the taut tight-fitting stretched cable inside the detector shaft. Gone were the days of messing with rewrapping loose floppy cables with Velcro with each coil change. Experience with the GPX 6000 in bushy areas has re-induced an external cable problem. Leaving a loose loop above the coil causes frequent false target sounds when swinging into or pushing under bushes. Normally setting and raising the detector is a small percentage of the time spent in detecting. Sounds generated during those motions can be accepted. Have a good day, Chet

-

Thinking of the present situation and a possible solution; In the world of corporate profits Minelab probably does not gain much on the selling of additional coils for any detector that they sell. In past years they probably have profited more through more sales of detectors by allowing other competing coil manufactures to produce a wide array of available coils at competitive prices. Two Minelab software changes would allow existing coil manufacturers to very quickly provide a wide variety of coils for the GPX 6000. Those changes are to remove the Coil ID and Security check; Replace it with a check to test for a signal/noise present or not present on the Double D receive coil. If a signal/noise is present then a Double D coil is connected. If no signal/noise is detected then a Mono coil is connected. Removing the ID and Security chip simplifies and reduces manufacturing technical processes and costs. This will provide both a better profit margin for the manufacturer and a reduced cost to the customer. In the long run allowing an open competitive coil market will sell more expensive detectors as it has with the previous GPX series machines. Have a good day, Chet

-

It is hard to understand why Minelab has again closed the door with proprietary connectors and security chip methods to prevent aftermarket coils if they don’t intend to provide other coil choices to their customers. The X-Coil method may again be the only option for other coil options for the GPX 6000. Minelab has certainly made it more difficult to make an adapter but if it is accomplished it will open up several coil choices. The GPX 6000 11” Mono coil has the same electrical specifications as most previous GPX series coils. That is; the inductance is close to 300 microhenrys (uH) and the resistance is close to 0.3 ohms. And shielding appears to be similar. If the X-Coil adapter method is wired to a standard 5 pin GPX connector configuration it should allow other X-Coils that are already built for GPX series detectors to be used or adapted to the GPX 6000. Existing Minelab GPX series Mono coils and other aftermarket GPX series Mono coils, depending on the quality and shielding effectiveness, may also perform well with the X-Coil adapter method. A workable and performance quality list could be established by a few users that still have GPX series Mono coils. The GPX 6000 Double D receiver coil is different from previous GPX series Double D coils. It appears to have a capacitor in series with the winding and appears to have more turns in the winding. Using existing aftermarket Double D coils on the GPX 6000 would probably not perform well. X-Coil would most likely be the only supplier of GPX 6000 Double D coil options for such a small niche market. Have a good day, Chet

-

-

I grew up in a logging family on the Oregon coast. We had plenty of complaints about the US Forest Service and their rules and controls. Some of my old complains have carried over about road closures into areas that have gold. I decided to goggle some facts on the USFS. They are responsible for 154 national forests and 20 national grasslands containing 193 million acres They are responsible for more than 380,000 miles of roads in our national forests and grasslands—that’s eight times more than the U.S. interstate highway system. The Forest Service has a workforce of approximately 30,000 employees. Even with seasonal workers and firefighters the numbers are remarkable. I now have a better understanding of their problems. Have a good day, Chet

-

After soaking overnight in CLR my 6.2 grams dropped to 5.98g. I didn’t test the GPZ 7000 on any of the GPX 6000 undug nuggets. I did fire up the 7000 and hunt for less than an hour as I used the built in GPS to home in on two Find Points from five years ago. As many of us do, I slowly circled and crisscrossed tens of yards all around those dig holes at that time with the GPZ-14 coil. I marked the old filled-in dig holes with dead sage brush and took the 7000 back to the Jeep. I didn’t want to drag around that heavy 7000 when I was enjoying using the 6000! I returned with the 6000; found two small nuggets each nugget was within three feet of an old dig hole. Then I found the 2.6g nugget less than a hundred feet from either of the old dig holes. This was in ground that I and others had been over several times over the years. Have a good day, Chet

-

When will GPX 6000 17” Mono Coils be available? Will Minelab produce any other coils for the GPX 6000? Smaller Mono and Double D elliptical coils would be useful in gullies and brush. Minelab may again do a disservice to both their dealers and customers by preventing other coil builders from providing competitively priced custom coils for the GPX 6000. While at the same time they may again not provide additional Minelab coils that are desired by customers. Short time materials shortages or small ID-chip shortages may not be a valid excuse for not having relativity small numbers of coils to be manufactured by Minelab subcontractors. Minelab should provide the dealers and customers a reasonable path ahead for additional coils. If they don’t have a clear and timely path within the company then they should open the door for competitive coil manufactures to produce them. The fastest and most cost effective way to do this would be for Minelab to patch the software to not test for an ID chip within the coil. Instead only test for an existing Double D receive coil winding. If the Double D receive winding is not detected then it is a Mono coil. This software patch would allow coil manufactures to go into production quickly without additional wiring, ID-chip programming and testing and associated electronic equipment. This would also reduce production cost and reduce final cost to dealers and customers.

-

Norvic in HAM talk; we may need to work out detecting days or hours between countries to avoid generating EMI between us via the Ionosphere Skip during the Solar Max period LOL. This could explain the frequent need to retune our detectors as the Ionosphere is changing between us lol.

-

GPX 6000 - Tips, Tricks, Technical Questions

Chet replied to Northeast's topic in Detector Prospector Forum

Maybe this is where some of the GPX 6000 chips are made. https://news.yahoo.com/trucks-fresh-water-used-feed-130941849.html -

Another Ghost Nugget & Hoping The Gpx-6000 See's It

Chet replied to Gerry in Idaho's topic in Detector Prospector Forum

Hey Gerry as soon as that GPX-6000 gets here I am heading for Nevada. So I will meet you there for some more hunting time together. Have a good one, Chet -

Another Ghost Nugget & Hoping The Gpx-6000 See's It

Chet replied to Gerry in Idaho's topic in Detector Prospector Forum

Ghost Nuggets vs. Pulse Induction (PI) Detectors vs. Very Low Frequency (VLF) Detectors: Disclaimer; some liberties have been taken in this write up to simplify a very technical subject into a simpler understanding of what is going on. Pulse Induction (PI) detectors transmit very sharp powerful pulses. At the end of each pulse the receiver is quickly turned on to receive a very weak signal from electrical currents that are still circulating but quickly dying out in the gold nugget. The length of time that electrical currents continue to circulate is dependent on the conductivity and amount of conductive material and the shape of the object. The overall design and timings of the transmitter and receiver and effective coil size determine whether the smallest nuggets or only the larger solid nuggets at depth will be detected. Ghost nuggets contain small gold wires and/or small flakes of gold scattered in a quartz specimen which have very short periods of electrical current flow. In Green’s charts and wire table this short period of weak current flow is referred to as a Short Time Constant. Solid nuggets have long periods of electrical current flow (Long Time Constants) along with much greater signal strength which can be detected easier for a much longer period of time after the transmitter has turned off. In Very Low Frequency (VLF) induction balanced detectors the transmitter and receiver are always on. When the null balance of the VLF coil is disturbed by a nugget the signal is processed to determine how much delay or phase shift in the signal has occurred. The results of the phase shift evaluation is displayed as a ferrous or non-ferrous value. If the nugget is tiny the phase shift will be too small to give a reliable ferrous/non-ferrous display value. A dig anyway flag! In the case of a Ghost Nugget the accumulated sum of all of the small wires/small flakes will give a good unbalance of the nulled VLF coil. And usually sufficient phase shift to indicate non-ferrous/gold. So what Gerry and some of us are hoping is that the GPX 6000 improved design and processing will allow it to detect the very Short Time Constants of some of the Ghost Nuggets. Have a good day, Chet -

Another Ghost Nugget & Hoping The Gpx-6000 See's It

Chet replied to Gerry in Idaho's topic in Detector Prospector Forum

Hi Green There are a few lead shot tests here; https://www.youtube.com/channel/UCEN_BLb2wrHNkGzP3iDOJMw Have a good day, Chet -

Jonathan What outstanding information! Minelab should hire you to rewrite their manuals! Good manuals sell products. I will take this information to the field and put it to work. Thank you and have a great day, Chet

-

I have been using the SP01 with two shoulder speakers for some time. And the separate volume control is better than just the 7000 volume control. Recently to reduce weight I removed the SP01 and speakers and went back to a single WM12 on my right shoulder. I also removed a bunch more stuff off of my harness and belt. It feels a lot better now. I may go back to the SP01 latter.

-

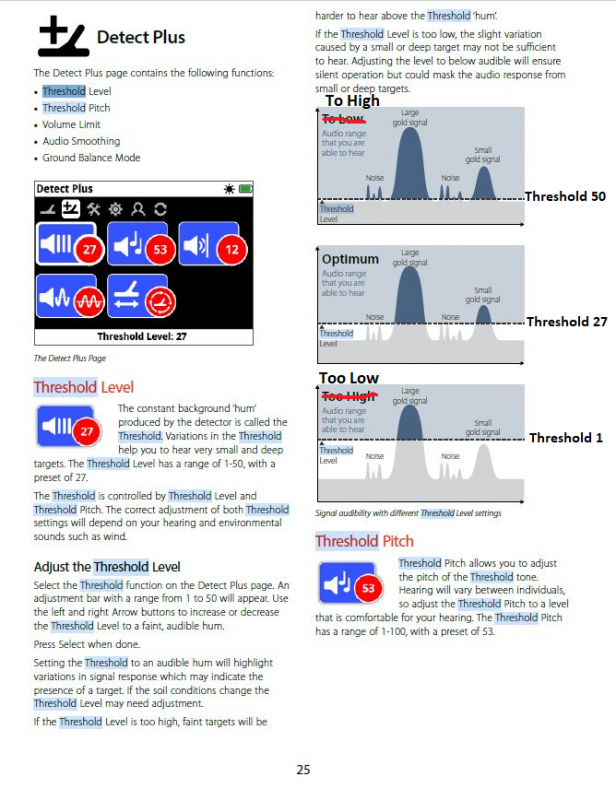

Northeast and Arky, I am hard of hearing so I run the volume around 14 with the WM12 speaker. With mild ground I run the Sensitivity at 20. My first 7000 also had a noise problem when the battery would get around 50 percent down. It would get very noisy; if I put it on the car charger for 10 minutes it would quiet down until the battery got low again. Minelab replaced it quickly with help from Gerry’s. OZMOG’ I agree the 7000 is in general noisier than the 5000. On the right side chart where I have added the Bold Threshold numbers; my machine sounds like its running near the top rather than at 27. Mitchel, Lunk was one of my trainers; I have tried his settings but his Threshold of 35 is just too noisy for me. Jason, you pass the test on also catching the To/Too.😎 Steve, the “-“ sign would correct the number/value problem; but Tarsacci might have a copyright on it.😂 Thank all of you for the great comments; my plan now is to jot them down and try to apply them this spring on a trip to Nevada. Also I will compare machines and settings with someone else that is running quiet. Have a good day, Chet

-

For years I ran the GPX 5000 Threshold setting with a faint audible level by following the book; which is condensed as follows; Through a process of dynamic noise compensation, Smart Electronic Timing Alignment (SETA) ensures that the threshold stability is improved and maintained, allowing you to operate the GPX 5000 with maximum efficiency under all conditions. Threshold is the constant audible background hum or noise produced by the detector. On the front panel rotate the variable Threshold control to achieve a very faint but still audible noise level. It should be smooth with only minor fluctuations. The Threshold is your reference point and lets you know what the coil is sensing, whether it may be a target, ground noise, or electrical interference, so it is important to set the threshold so it can be heard. When a target is detected, the Threshold changes in volume and pitch. Listen to the threshold carefully. Concentration is an important part of detecting. A very deep or small target may only cause a very small change to the Threshold noise. Listening for a target signal with a high level of Threshold noise would be like trying to hear a whisper within a crowded noisy room. A high Threshold may also be uncomfortable to your hearing. If the Threshold level is set too low (less noise) very soft target signals, from small or very deep targets, may not be heard. It is important to reset the Threshold level as conditions change. For example, your ears may adjust to the low levels of audio after an hour or so, or the conditions may have become windy. So here are my concerns; With the GPZ 7000 I find it difficult to achieve the low quiet hum of the GPX 5000. I get the trying to hear a whisper within a crowded noisy room effect. The constant high noise level makes it difficult to listen for small changes that would indicate a small shallow or large deep nugget. So I tend to run it far below the default setting of 27. And much of the time I run at a setting of 1. Another problem is related to the control differences between the two machines. The GPX 5000 has a simple variable Threshold control with no numbers to be concerned with. The GPZ 7000 has digital values which appear to be inverted in function. Attached is an edited illustration from the GPZ 7000 manual that displays my view or understanding of how it should be described.

-

Lady In The Golden Robe... Needs Your Help

Chet replied to Gerry in Idaho's topic in Detector Prospector Forum

Guitar pickups are sensitive to steel or iron. So use a small piece of tape or glue to attach a light piece of iron to the leaf. Then tap it like tapping a tuning fork. Get very close to the pickup by removing the strings. -

Thank you that is good information. Need to study it more.

-

Hi Green Nice work. Could you provide the weights and diameters of the lead shot. Maybe display them next of a mm scale or 1/4" graph paper like the nugget displays. Have a good day, Chet