-

Posts

5,842 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by GB_Amateur

-

Beach Season Has Begun

GB_Amateur replied to schoolofhardNox's topic in Metal Detecting For Coins & Relics

Great detecting attitude, school. I can see why you are so successful. I'll speak for both myself and the rest of the animal world and thank you for picking up plastic trash. Now, go find some precious!- 206 replies

-

- 4

-

-

- coin detecting

- minelab equinox

-

(and 1 more)

Tagged with:

-

We've had nice weather here in the Midwest the past week or so and after getting out Wednesday I was doubling up on Thursday afternoon. The curve ball mentioned in the thread title was breaking an ML Equinox 11" coil ear when loading the car, which I described in the appropriate thread. Fortunately I have both the 6" and 12"x15" coils (but not the Coiltek 5"x10" yet). I'm detecting a park with not too much iron or aluminum trash so I figured the large coil would be OK, as long as it didn't mess up my elbow swinging a heavy coil through the deep grass. (Wet and warm early autumn hasn't met with the Parks Department's mowing budget....) First target was showing low 20's (typically an aluminum screw cap) and out popped a clad dime. Hmmm, that should have been 25-26. Was the larger coil giving different dTID's. Going back over the hole answered the question -- 20-21 and out comes a Zincoln. I don't think the two coins were touching but they were super close to each other leading to the anomalous dTID initially. 15 minutes into the hunt I get a Wheatie, not too deep (3-4 inches). That's the age coin I'm looking for. Maybe an hour later after the typical occasional can slaw, a couple rusty nails, and a few modern coins I got a nice sounding but inconsistent tone & dTID. From one direction as I swept close to the target location left-right I was getting hi-lo-hi-lo... tones (14-19 = pulltab zone is set for a medium tone whereas 20 and up are high tones; the tone was alternating between these two). This is not typical of coins in my experience by any means so I'm thinking a flattened, non-symmetric aluminum screw cap. I don't remember the exact strength indicator value but I'm sure it was at least 5, maybe mostly 6, possibly occassional 7. I also don't remember the dTID at a 90 degree compass change angle of approach but I'm sure it was at least high 20's (large, elongated can slaw?). The tone volume told me it wasn't a near-surface coin-sized object. Definitely good enough to dig. Weak(er) signal strength means take a good sized plug so about 7"-8" diameter and 5" deep was my start. The Garrett Carrot (set at max gain = 3) said I was in the right spot and switching to the fine tuning White's TRX told me I had a localized (coin-like size) target which was between 1" and 2" deeper than the current hole depth. I carefully cut about a tennis ball sized chunk of dirt centered on the TRX signal's centroid and upon removal was told the target was in that glob. Breaking it up with my fingers I saw a coin but it wasn't immediately obvious if modern clad or silver. Again, careful not to scratch I picked off a clod of dirt and saw the familiar (from dimes I've found ? Barber Head. See middle coin in photo: Only my 3rd silver quarter ever and 1st Barber Quarter, others being Washingtons. (Guess I'm going to skip the Standing Liberties. ) Even better than being 19th Century date was the -S mintmark. Left coin in the photo is actually a 1919-S which I found the previous day probably less than 10 m away from where I found the quarter. So -S mint oldies in consecutive days, and neither is particularly common although neither is a semi-key. On the right is a 1941 Merc which I found last week, so three consecutive hunts with non-penny old coins. That's very good for me in my current public sites. Why the anomalous dTID from one direction? I wonder if the coin was oriented on-edge. So what's the big 'A'? Some of you recognize this as the Atlanta Braves initial. For those who don't follow our North American professional baseball, they just won the annual championship (not so modestly called 'World Series') for their first time in a quarter century. They were underdogs vs. at least their last two playoff opponents. But there is a detecting connection. I sometimes hunt in rural areas during Autumn and that is prime (gun) hunting season. I have other bright (orange) garb but I wanted a baseball cap (easier to accomodate headphones) and I saw this hat at a flea market for $5 a few years back. I wonder if I can sell it now for a profit. Anyone interested?

-

I'm with you, strick. My go-to mantra (with exceptions, as always) is "if it ain't broke, don't fix it." Next in line: "if it is broke, try the minimum fix first." Having spent most of my career in a position where I and my cohorts were doing things no one else had likely done (nor wanted to for that matter) we tried a lot of 'solutions'. Sometimes the cure was worse than the disease because of over-design.

-

@Joe D. Thanks for the tip. A couple things: 1) I'm not using the Eqx bolt+nut becauase I use the ML X-Terra lower shaft and that takes a smaller size. 2) There was a YouTube video posted here (can't remember anything but the images and content...) by a regular YouTube poster from Southern USA (some kind of thick accent...) where he experiments with different adhesives and epoxies. The one I've chosen did best in his testing. It actually interacted with the pieces being attached -- almost like melting and re-solidifying. I like that solution but don't know if it will work for the plastics I'm using. I'll find out.... I've tried multiple epoxies in previous garage mods, including two whose manufacturers claim will bond injection molded plastics. They all failed.... The one I've chosen for this task hasn't failed me (yet) because this is the first time I'll be trying it. ?

-

@steveg I don't see why you multiplied by 2. My measurements weren't of the individual washers but rather the 'assembled' size (washer + shaft well + washer). But 10 thousandths of an inch (1/4 mm) out-of-tolerance being a problem -- I can at least envision that. Thanks for your confimatory response. The stock X-Terra washers aren't flat but rather have (large) teeth in the back which fit into cavities in the shaft to prevent them from rotating. (Why did ML engineers go to that much trouble to prevent rotation of the washers? I don't know.) But, yes, the stock Equinox shaft (and also the X-Terra replacement aftermarket Anderson shaft) have the simple flat washer for which a shim is easily accomodated. I wonder if the 'phrunt solution' of lubricating the washer with silicone spray reduces the amount of frictional wear. I did lubricate mine quite a while back but I think I'll try doing that every 15-20 hours or so of field use.

-

Add another datapoint to the breakage bin. On Thursday, with nice weather (~50 F = 10 C) and sunny I was loading my gear into the SUV for an afternoon detect in my current site (muni park previously an industrial yard). When travelling near home with my detector I just leave the shaft extended to it's optimal (for me) length, coil attached -- ready to hit the ground running. It fits across the floor of my backseat just fine. I've been doing things this way since I got my ML Equionox 800 in late March 2018. (Relevant Note: 3 year warranty has expired). As I was putting the detector in the back seat (coil first...) I bumped the coil on something, probably either the near car door (standing open) or more likely the back of the front seat. I heard a 'crack' sound, not too loud, and at first was going to ignore it. And then I remember this and many other threads on the same subject.... Taking the detector out and looking at the coil attachment area it didn't take but a fraction of a second to see the source of the noise. The top of the tab had broken completely through at the location where the through bolt passes. Fortunately I had my 6" coil in the vehicle (always try to bring it along) and better yet, the 12"x15" inside so I put on the latter and my afternoon hunt survived. (I'll make a separate post on the results of that, which included a detecting first for me. Stay tuned for that.) I did check the tightness of the wing nut and it was not very tight; definitely not what I would call over-tightened. Further, thanks to phrunt's suggestion I've been putting spray silicone lubricant on all my rubber coil gaskets (not just on Eqx but on other detectors as well) to minimize the friction when the coil is rotated. I will state (obviously without proof) that I didn't use a lot of force loading the detector and that I'm confident I've torqued the coil similarly on many occasions in the past without incident. Now let's review the history of this coil while in my possession (since it was new in box). Only counting local detects and only counting days when the only detector+coil I used was the Eqx+11" stock, reviewing my detecting logs I see that I've hunted with this coil for 820 hours. I probably have another 40-80 hours with the coil if I were to include remote hunts (e.g. this past June in Utah and this past August in Massachusetts) plus those days when I hunted with multiple detectors or the Eqx with multiple coils. Probably more relevant is that I've modified my shaft by replacing the two lower sections with the ML X-Terra 705 lower sections so in fact the Eqx coil(s) is attached to an X-Terra lower shaft. Does this enter into the investigation? Yes. Let's delve deeper. Of those 800-900 hours that the 11" coil has been in use, between 450 and 500 of them (the most recent) were with this modified shaft. Could there be a tolerance (would 'intolerance' be a better word) issue? Here are some measurements I just made this evening. (Note: measuring soft items is a bit tricky but more complicated than that, measuring a stack of items in which there are 'mushy' contacts between them, such as rubber gaskets embedded in plastic insets -- exactly what we have here -- leads to some measurement uncertainties. Thus I give a range of thickness measurements for each combination.) 1) My Equinox stock shaft with used = ~400 hours wear gaskets: 0.890-->0.899 inches. 2) My current setup (X-Terra lowest shaft w/used = ~500 hours wear gaskets: 0.882-->0.884 inches. 3) Brand new (unused) Anderson lower shaft for X-Terra with one shim (included in purchase and determined by me to be the right amount of adjustment): 0.894-->0.897 inches. 4) Brand new (unused) ML stock X-Terra lower shaft purchased from Gerry earlier this year: 0.896 --> 0.902 inches. 5) Opening on my slightly used ML Equinox 12"x15" coil: 0.889-->0.894 inches. BTW, for those who prefer metric measurements, 0.010 inches is about 0.25 mm. Looking over these numbers, the X-Terra and Equinox shafts are likely pretty close when everything is new. The thing that jumps out is that my used X-Terra lower shaft (gaskets 'used' exclusively with the Equinox coils) are about 0.010 inches thinner than everything else. I don't know if we can call that a smoking gun, but it appears those gaskets have worn over time. Is that current combination enough to lead to stress that caused this breakage? I guess Minelab engineers should be able to answer that -- they've seen enough returned coils with broken ears to figure out what's going on.... To add a bit more evidence (admittedly anecdotal), I do recall measuring things when I changed from Eqx stock shaft to X-Terra shaft almost 2 years ago and the difference then was not 0.010 inches or I would have added shims to make up the difference. I don't know how the gasket compounds compares between Equinox and X-Terra but it sure appears that the X-Terra gaskets wear measurably with time. (I have a spare set of those plus the ones on the shaft I bought from Gerry. Time for a change now that the horse has escaped through the open gate....) So, what next? This next picture (with broken coil attach tab piece and bakelite washer I've had salted away since I was in high school > 50 years ago) gives a big hint. I'll report the results of this garage fix in a couple days after I see if it works. Update: first a picture of my gluing jig: 5/16" drill bit (8 mm would have been slightly better but I don't have one of those) and three stop collars. Two of the stop collars 'pin' the (broken) ear and reinforcing bakelite washer in place. Note: epoxy likes to bond metal so I waxed (with automobile paste Carnawba wax) the drill bit and the stop collars. One of the stop collars and the drill bit still stuck but my handy ViseGrip and careful rotation of those broke them loose without damaging the new joint -- all that after an overnight cure. Here is the finished fix: I lightely filed (with a very fine file) the inner tab surface that mates with the shaft's washer just to clean up any epoxy overslop. Next step is to silicone spray lube new washers and give it a go in the field. Unless my fix fails I see no need to report back (other than posting pics of all the goodies). Fingers crossed. ?

-

Is it just me, or are some people nitpicking about the 20 m depth capability because "it might be wired"? From a curiosity standpoint I understand the question. But from a performance standpoint, why should you care? Has XP ever claimed something would work and it didn't, or it did but was over-blown? If this thing is simultaneous multifrequency (it is) plus works to 20 m water depth (which they say it will), why aren't those in the ocean detecting (and even some in the freshwater detecting) camps throwing wild "can't wait for the release!" parties? What am I missing here??

-

"What's the better detector for the masses?" "What's the better detector for a seasoned expert?" "What's the better detector for a specific individual?" Determining the answer to each of these questions doesn't necessarily lead to a unanimous conclusion. In the case of specific individual, is the question about today or in the future? (Here you can quote Yogi Berra, whether or not he really said this: “'It's tough to make predictions, especially about the future'” )

-

Little City Park Giving Up The Silver

GB_Amateur replied to Dan(NM)'s topic in Minelab Equinox Forum

Just another day on the time machine you've been riding.... And more silvers than Wheaties; 8 to 5 -- it wasn't close. That happens, like, never? I look forward to your next report, but not as much as you are looking forward to tomorrow's hunt. -

Welcome, botics! Sounds like you dip your toe in every form of detecting: beach, native gold, jewelry, coins, and relics. And you have a good arsenal to attack those targets. I look forward to your stories, past and present.

-

Lots of good ideas and this is one of those questions that has no 'best' answer. It depends a lot upon the person. Are you happy finding a few dinks each time or would you rather go for the gusto, realizing you'll strike out most of your times out in the field when searching for new ground? There are so many parallels between the different forms (specifically target goals) of metal detecting. Due to where I live I mostly detect parks and schools for old coins. I realize those are easier to find that patches that yield. Finding old coin sites that no one else has searched, or at least the skilled detectorists haven't searched much is a different matter. I know I've left good targets behind because I've proved it on multiple occasions. Just this year I decided to go back to a school I've detected a lot and went over a spot I could have sworn I'd been over at least twice, with both the Fisher F75 and ML Equinox. I found a silver dime (Merc) less than 3" deep. It was pretty much there in the open, not close to any trash -- loud and clear giving a high tone as it should. Obviously I hadn't swung a coil over it in the past, regardless of what my memory told me. I have a feeling most people think they cover ground better than they actually do. I try to think "mow the lawn" but besides seeing your own footprints it's usually hard to know exactly where your coil has been. On more than one occasion when I had a line-of-sight goal in the distance I was walking towards, when I looked back at my tracks it look like the classic drunkard's walk. There are better ways to monitor path but you still have to get the coil over it all, and the deeper the target the more overlap is necessary since less then the full coil is sensitive as depth increases. (All of this is well known, but that doesn't mean it's well applied....) Do what makes you feel best and don't burn any bridges that lead back to those familiar patches.

-

That's a great design (and you have considerable mechanical drawing skills -- I'm impressed!). A couple years ago I built an in-ground double barrel shotgun style test setup using PVC pipe with wooden pistons for holding tagets. I can use those pistons for this and I probably already have plenty of the small pipe in my garage. I just need to buy the large pipe and maybe a hole saw to drill the holes. I'm on it! (Do I owe you a design fee? ?) Although the edge effects will not give quite the full 3-d ground coverage of the real world, results from this setup are going to quite informative. Thanks!

-

Yes, and yes. Consider weather modelling (a much more difficult problem for sure, but also one that gets 100's of millions of $ of annual support because it impacts the entire poplulation of the world, not the miniscule subset of metal detectorists, let alone the minute number of that group who even care about this subject). Knowledge of weather was known at some level for millenia yet it is only in the last decade or so that computer models have become reliable for short term (1 day to maybe 3 days?) and a week or longer predictions have large uncertainties. IMO there is little doubt a continuous spectrum of objectivity exists, and the more data the better. As far as irrefutable, the only time that happens is with problems so trivial their results aren't impactful or someone is burying his/her head in the sand accepting nothing more than beliefs. Is the Monte Nail Board Test of value? Is that as far as we can go to get meaningful results?? Finally, is it worth the effort??? (hint: More question marks at the end of a sentence indicates it's a tougher question. ?)

-

While we're all abuzz with the announcement and advertised feature and performance characteristics of the XP Deus II, I'm wondering about tests that distinguish between detectors' target separation abilities. 'Word on the street' is that in trashy iron sites, the original Deus is still the best available. Presumably those reports are based upon in-field testing, which of course is the real proof. But the downside is, (AFAIK) these are qualitative observations, not quantitative. Subjectivity involved? Unfortunately, yes. We do have Monte's Nail Board Test for a special case -- iron nails near a single coin, all in the same plane and typically all on the surface of the ground. Add depth combined with some mineralization (burying the MNB) and you've included another real world dimension. But in the field, multiple nearby targets are seldom in the same plane. So you hopefully see the purpose of this post. Has anyone seen/tried other methods to better simulate actual in-field conditions to differentiate between competing detectors to best be able to handle trashy sites?

-

OK, I understand the Left Hand part of this graphic, but the RH? (Full disclosure: I don't understand French. ) The red lines are for FMF operation and the others represent different single frequency operations. But what specific performance advantages are being displayed? Here are some thoughts (which may be all wet): 1) You can't beat FMF in performance with any single frequency; 2) for iron discrimination and for large targets, there's a monotonic performance relationship with frequency; 3) for small targets, the opposite relationship (i.e. opposite compared to large targets) holds; 4) for medium targets, all single frequencies (as well as FMF) perform equally. I don't think I'm overstepping to say that this diagram is just a general 'rule' and that exceptions abound. Which end of the frequency spectrum caters to large targets and which to small? (If gold detector performance is any indication, higher frequency for small, etc.)

-

Two Short Hunts At A Tapped Out Site

GB_Amateur replied to F350Platinum's topic in Metal Detecting For Coins & Relics

Well that sucks. Sorry to cause you to repeat. I'll pay more attention from now on. (Promises, promises ?) -

Two Short Hunts At A Tapped Out Site

GB_Amateur replied to F350Platinum's topic in Metal Detecting For Coins & Relics

Wheats, IHPs, a few relics -- some going back to the 1800's. You've got a good spot there! Grass looks really long but you're still pulling out goodies. I recall you've told us about the horse track before -- more of an informal one (kinda like Discovery Channel's Street Outlaws except horses, not cars). Have you been able to find out how the horse track was laid out (e.g. which direction they ran) where people congregated, where money changed hands(!)? The finish line in particular should have been a gathering spot. Everyone wanted to see who wins so they make sure to get paid fairly.... I gotta think there is some sliver there just waiting for you. Maybe big silver! -

15" Coil Strikes Silver Again

GB_Amateur replied to Againstmywill's topic in Metal Detecting For Coins & Relics

I've found more Mercs than Roosies. It may have a lot to do with when the coins were minted and when silver was pulled from circulation. Mercs never really left circulation caused by their age. So from 1916 to ~1970 there were Mercs in circulation, some getting dropped/lost for us to find. Roosies started their life in 1946 (30 years later than Mercs) but 'died' at the same time -- around 1970. So less time to get lost means fewer for us to find. As far as mintages, I haven't done a study but the later Merc mintage figures (i.e. those from 1939 to 1945) they really cranked 'em out. There were more individual date+mintmark coins for over some of those 7 years than any Roosie date+mm in the (late) 40's thru the 50's. It took until the 1960s for the mint to match production during those late Depression and early War years. Besides, the Mercs are way prettier! -

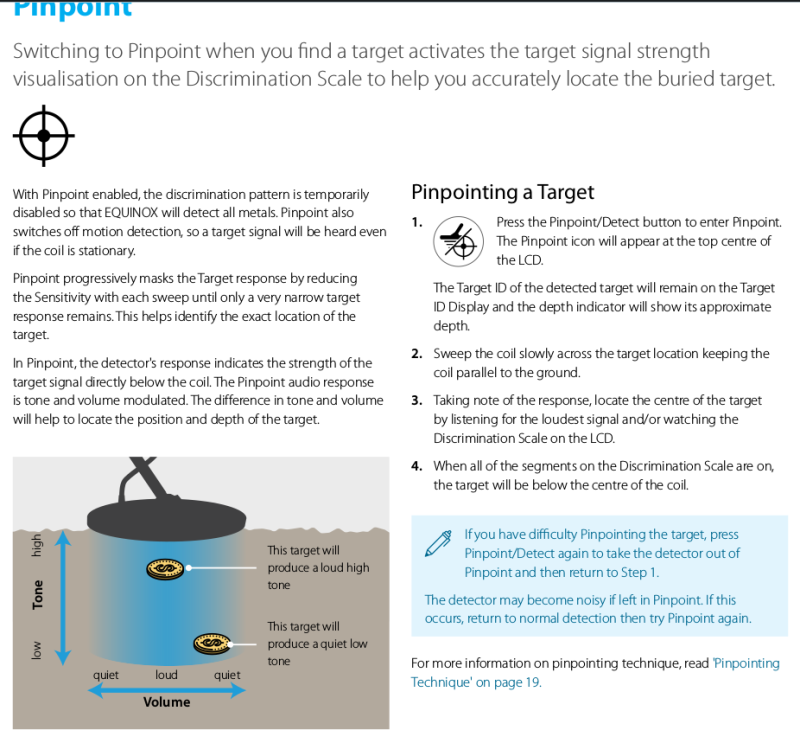

Ok, it's been 10 days since the original post was made in this thread. I'll chime in now. For starters, here's the page in the manual that covers the Pinpoint function: If you have an Equinox, are interested in using the pinpoint function, and you haven't read it previously, now's a good time to do that. And if you have read it before, read it again! nwdetectorist mentioned part of the coverage of this topic by Andy Sabisch in his book. The full description/instruction begins on p. 45 and goes through p. 47. I just reviewed that as well. It's very good, but IMO not as good as what I'm going to say below. #2. Important note: what I relate below is a combination of things I've read (e.g. manual page above, Sabisch's book, posts here on this site) and things I've figured out on my own. Unless specifically called out, from now on just assume these are my opinions (so I don't have to keep repeating 'IMO') based up all of those forms of learning, and keep in mind what I say may not be accurate. (Everyone could say that on just about every post, but I'm going to emphasize it here. Proceed, if you wish, with this in mind.) 0) The pinpoint function (PF) on the ML Eqx has some good features and some bad ones. As has been noted in some posts above and much previous literature (here and elsewhere), there are many ways to pinpoint a target. The pinpoint function is a tool but shouldn't be used exclusively. In my case I use many methods, sometimes all of them on a single target. But keep in mind that many people prefer not to use the PF, for their own reasons and preferences. Also, the Eqx PF has some things in common with other detectors but you'll be confused if you expect it to do all the things exactly the same as your other detectors PF functions do (more below). 1) The PF has both audio and a visual indication. Obviously you can use either or both. I'd estimate that I use the audio part of PF on at least half of all my targets, but the visual tool on only a few % of finds. Basically, the visual tool (common to the ML X-Terra series, and maybe others) has an open circular ring around the outside of the display which fills in completely when centered over the target. At least that's the intent. As Sabisch points out, for very strong targets that saturate this feature, the ring can fill in before you get centered. Detuning necessary. More on that later. 2) The manual mentions "tone and volume modulated". Volume, yes, but tone pitch? That is subtle at best. One of the earlier posters said it was a VCO audio and it might be, but it's nothing like the VCO I've heard on other detectors. I depend solely upon tone volume for audio determination of target location in PF. 3) There is an annoying occurrence which has been noted (complained about?) since the Eqx was released -- sometimes when activated, the sound from PF is muted and barely audible. I think one of the software updates addressed this but it didn't completely eliminate the problem. Sometimes moving away from the target, waiting a couple seconds, and returning solves the problem. But so does moving to the side, getting out of PF, and then restarting. These both take about the same amount of time and the latter one is probably more reliable. 4) One thing I disagree with the ML manual above where it says: "The target ID of the detected target will remain on the Target ID display and the depth indicator will show its approximate depth." Those statements are inaccurate and misleading. Both of these indicators are frozen in their respective positions when the PF is activated. The best location of the coil for determining the optimal readings of these two features is directly over the center of the target when in motion modes, not pinpoint! As you move away from the target, getting ready to activate PF, you typically get a dTID and a strength indication but those won't be optimal because they are reflective of what the detector picked up when you were moving off to the side to activate pinpoint. (Some detectors give accurate digital target ID's and depth while in PF. The Eqx does not. I suggest you ignore both when in PF.) 5) PF works best when the coil is kept at a uniform height above the ground when moving the coil after activation of PF. The easiest way to do this is to have the coil in its 'natural' height -- the same height you keep it when searching. But sometimes (see below) you may want to keep the coil well above the ground so in this cases be particularly careful since it's awkward to maintain a unifrom height in this unnatural position. 6) As noted in the manual and in the Sabisch book, the PF has a dynamic detuning feature which personally I find annoying, frustrating, and worse than worthless. They should have given users the option of turning it off. Fortunately it's slow enough to activate that most of the time I don't notice it. Also fortunately, they include a manual method for detuning which is quite useful. OK, after all these caveats, let's start with the simplest use of locating a small target and then go into the initial poster's request of target sizing. You've found a target you want to investigate and would like to accurately pinpoint it for further investigation and/or recovery. While still in the search mode, move the coil to the side (toward or away also works but to the side is better) until your detector goes quiet. How far to the side? Well, you often don't get complete freedom because there are other targets nearby. Somewhere between half a coil radius and the full coil radius (5.5" for the stock coil) is usually good. Just make sure it's far enough for the detector to go silent. Press the pinoint button. (Note: unlike some detectors, this is a toggle switch so not only don't you need to keep it held down when pinpointing, you shouldn't. PF stays on until you press the button again.) Then move the coil (at a moderate to slow pace) back over where you initially determined the target to be and when you get a tone, move it around side-to-side and front-back to get the loudest sound. If you want to use the visual feature of PF, watch the screen and when all of the segments of the circular ring are highlighted, you've found the target location. Because of the DD nature of the coil windings, pinpointing with left-to-right motion is more profound/crisp than forward and backward coil movement. Thus to really get an accurate location, you can walk around the target and just move the coil left-to-right, noting the location that gives maximum volume at multiple compass directions. If the target gives a strong (loud) PF signal, the manual detune feature comes in handy. At a coil location where you still hear sound from the target, but not at the volume max, turn off PF and then turn it back on. Now move back over the target and not only will you get a less ear-blasting sound but also a sharper location. If the extended target is particularly large/loud you may want to activate and subsequently move the coil (off center, of course) when it is elevated considerably above ground level, e.g. 6 inches above. OK, what about sizing medium to large extent targets? While in search mode, move the center of the coil a coil radius (or a bit more, as necessary) away from the perceived target location, again making sure you are over 'silent' ground, not the intended target and not a nearby target. Activate PF and rather slowly move towards and eventually past the previously perceived target location. If it's a non-pointlike target (i.e. extended) as you move the coil take note of when the sound appears and when it PF goes silent. Definitely move around the target and repeat. For example, if it's a linear target such as a horizontally oriented piece of rebar (i.e. parallel to the surface), in one direction you'll get the sharpest blip from there a 90 degree compass angle change will result in a long, drawn out tone. How about a paint can lid (again, let's assume oriented parallel to the ground surface)? Now no matter what compass position you choose, the length of movement from silent to loudest to silent will be about the same. Manual detuning over an extended target works, too. You can hone in on the centroid of the target by successive manual detunes. Now, a word of caution regarding not getting fooled by the dynamic detune feature. Let's say you've found a silent location near the target to activate PF. You then move the coil over the target and past it, encountering a strong(er) nearby target than the one you are interested in. If sufficiently strong, the dynamic pinpoint will kick in and when you subsequently swing back to your intended target you hear nothing. !#&*@!@%%!#&(!! You've got to start over and be careful not to get near that unintended target. Coming from a different direction might be the best solution. Sometimes nearby targets are so close and loud that PF won't even work at all for locating your intended target. You'll have to resort to other pinpointing methods in those cases, or dig and remove the nearby bully target and then go back to locating your intended one. I do this fairly often when I encounter a undesired large target near my intended (hopefully good) target. Another word of caution, if you don't keep the coil at a uniform height when moving it while in the PF you won't get reliable audio or visual reporting of location by the detector. One final note. A metal detector 'sees' the solid angular extent of a target, not its size. A deep, extended target may sound (when pinpointing as well as searching) like small pointlike targets such as a coin when using PF. As an anology, consider an approaching train which you can discern far in the distance. Looks pretty tiny. Hint: don't assume it's going to stay tiny and set up your picnic blanket in the middle of the tracks!! #3 (and final)

-

The Funeral Of The Sampson T-handle

GB_Amateur replied to phrunt's topic in Metal Detector Advice & Comparisons

Simon, if you still have your original Sampson that you had the shop weld up, would you post a picture? (I think the original post showing that fix doesn't exist anymore.) Here is a photo of the mod I had my friend do: The design is mine and maybe it wasn't the proper rework. I made the triangular gusset (from a piece of steel plate that I had found detecting). If I recall, the steel rod that is bent 90 degrees and is welded on one end to the (hollow) shaft and the other end to the face of the blade is what bent on Simon's. (Please correct me if I'm wrong.) Thus I thought the gusset would prevent that. My friend welded one edge to the hollow shaft as shown above, and the other to the foot ledge. As far as the (popular) WW Manufacturing Lesche hand digger, back in 2015 I bought one for me and one for my wife to use in the garden. Not long after that I bought a 3rd one so I would have a LH serrated version and an RH one. Here's a picture of my two: I don't think I've ever used the lower one, but the other I've been using exclusively for 6 years. You can see I filed off the teeth so as not to damage tree roots in park and school grounds. Next photo shows the problem I had with the original sheeth as well as the (new) $12 Treasure Wise replacement (from Serious Detecting) that I've been using for about the last year. That a fantastic solution and I've noticed no appreciable wear in that time. As mentioned previously, the Predator hand digger sheeth is similar to the nylon(?) WW one, except it has rivets on either side of the top opening. That would have prevented the problem I had, but I still prefer the leather Treasure Wise version. Bottom line is that for the hand diggers, the WW Manufacturing 'Lesche' model has been a great performer, just not the sheeth. -

The Funeral Of The Sampson T-handle

GB_Amateur replied to phrunt's topic in Metal Detector Advice & Comparisons

Let's break these into two pieces: 1) I'm not familiar with any of the details of the Lesche family split and will avoid taking sides on that particular issue in the future. 2) You can compare side-by-side some of the products in common between the WW brand and the Predator brand. There are differences and, IMO, Predator comes out on top in the couple cases I've investigated. Besides the WW Sampson vs. the Predator Ultra Eagle (similar but not identical products) another example is the sheeth that comes with the classic and ultra-popular hand digger. The Predator sheeth has rivets at the top where the digger enters the sheeth. The WW does not. I've worn out a WW sheeth at this vulnerable location. (Full disclosure -- I actually use the Treasure Wise sheeth which is sturdy leather -- with rivets!) Honoring warranties may be considered admirable, but OTOH it should be expected as SOP for every company. The fact that we've (myself included) become overly appreciative of such is another unfortunate result of the deterioration of company integrity that has been evident over the past 40 years. I prefer a company that both offers and honors a warranty, but also designs and builds products that are of such quality that the warranty isn't needed. -

With the stock 11" coil, often when I dig where I think a (good) target should be it ends up being a (ferrous) nail/screw/wire that is off-center, in fact, even outside of my typical 6" diameter plug/excavation. Coins on edge have also resulted in this well off-center anomaly. On a couple occasions my digging tool scratched a vertically oriented coin located along the edge of the plug.

-

The Funeral Of The Sampson T-handle

GB_Amateur replied to phrunt's topic in Metal Detector Advice & Comparisons

It is the same, unfortunately. After Simon had an expert welder modify the first Sampson he received (I guess the details of that post are long ago deleted), I took it to heart and had a friend (not quite as expert) weld a gusset to mine. He welded the gusset between the shovel foot ledge and the hollow shaft. The welding process blew holes in the thin shaft inintially but he was able to seal them up, more or less. From now on, Predator for me. Maybe a bit more costly (~20%?) but I buy tools to both work the way they are supposed to and to last a lifetime with proper care. -

The Funeral Of The Sampson T-handle

GB_Amateur replied to phrunt's topic in Metal Detector Advice & Comparisons

...or burrowing animals, earthworms,...