-

Posts

5,385 -

Joined

-

Last visited

Content Type

Forums

Detector Prospector Home

Detector Database

Downloads

Everything posted by mn90403

-

So The Beach Hunts Start Again

mn90403 replied to schoolofhardNox's topic in Metal Detecting For Coins & Relics

Well done again. I never find any silver coins in our wet sand areas. I would think when we have some waves bring old stuff up the slope it would be more than clad but years of experience says no. Our beaches have added 30-40-50 feet of sand over the last few years and even more over the last 50+. Every time I see your posts it makes me want to get my 5000 out on the beach again. I have a Coiltek waterproof coil for it and right now the beaches don't have many shallow targets. I'll have to get my big scoop out also. -

It is true that Minelab was using the pinch concept used by many detector manufacturers and coil manufacturers. What if you were to tighten some coil ears without a coil between the ears? It causes a pinching motion that would stress the ears to a point of breaking if the screw or other tightening device was completely tightened. It must break away if it has been molded. The 'concept' becomes a system (subject to patents possibly) when you select the materials, sizes, shapes, thread of the screws, bushings, lengths, etc. Ideally all of this will be stress tested in some lab multiple times before released for sale. One 'key' to the system selected is the play between the ears and the shaft connector. If you leave too big of a gap in the design, then you must look for 'shims' or bushings to reduce stress on the ears. Friction is required to keep the coil from flopping, and you increase friction with a tighter screw. That being my understanding, the 6000 system is much different than other systems that Minelab has used for CTX, eTrac, Equinox, Explorer type detectors. I don't own a 6000 and I can't guess what is making that system crack. Something is being stressed unless it is just plastic drying as the result of the curing process.

-

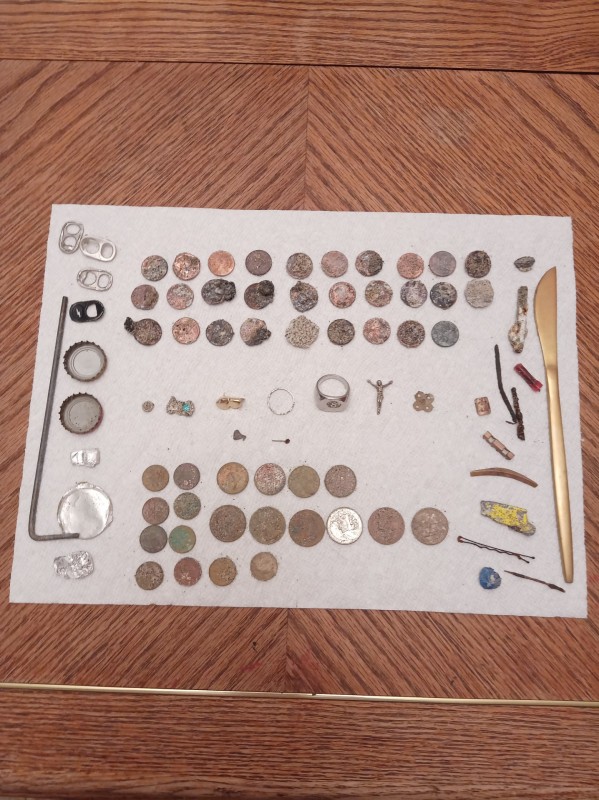

When you beach detect I'd say you mostly look for jewelry, or at least I do. (School is an exception to this 'rule!' haha) We find coins while detecting for the good stuff and we'd like to slot out the pennies and some other coins. It is not really possible with modern coins, especially the penny. Last night I was digging pennies with IDs beginning at 3 and going all the way to 28 on my 800/15. While digging all these corroded pennies I did find a couple of interesting more valuable objects. All of these pennies make me wonder how the Manicore is going to handle them. If you use some sort of automatic program ... how is it set? What are the adjustments? I think there needs to be a feature that will let you tell the type of metal the detector is seeing (copper, zinc, gold, silver, combos, etc.) but I think they try this on the ferris scale adjustments. As Strick says the 3030 lets you see things our other detectors don't. The pennies ... Ah ... gold teeth! Stainless steel ... (no markings) 16g ring with the lucky 8. I wish it was gold! It came in at a 10. A little savings ... The teeth were near the beginning and the 8 ring was near the end of 2+ hours.

-

Strick Picks Up Cutie At Brothel!

mn90403 replied to klunker's topic in Metal Detecting For Coins & Relics

Steve or Chase will have something to say about this! -

It is odd. Searching Bing and Google for: minelab gold toolkit gave no results!

-

A Fortunate Find After An Unfortunate Start

mn90403 replied to F350Platinum's topic in Metal Detecting For Coins & Relics

Permissions well used and shared. Thanks for showing us the recoveries and having a good banter and friendship after stepping on each other's ground. -

The coil ears are part of a 'pinch' system that Minelab has been using for years. Pinch the ears together more and the coil gets tighter. If you use less flexible plastics, they will break near the coil because there is no give. They will crack or separate from their attachments due to the torquing forces of the screw. This happened to me on my CTX 17" coil. I've always thought they should use a more flexible plastic formula but that would make the coil wear faster if you scrub it. My other thought would be to make the coil ears a bit longer which would make the pinching easier on longer ears farther away (half an inch or so) from where they come off the coil. I've also seen where some of their coil ears break at the screw holes. This I think is the result of a very tight screwed coil being adjusted often to level it for the swing. Those forces of leveling the coil cause a ripping action as a result of the tightness/friction in the pinch. Some sort of firm washer/anti-slip insert helped me with this.

-

This nugget was discovered 150 years ago! Flashback 1872: The Holtermann nugget and its fascinating connection to North Sydney. - Mosman Collective

-

What's the story? Pulse 8X Metal Detector (jwfishers.com)

-

Minelab Manticore Update Today (oct. 18th. 2022)

mn90403 replied to Gerry in Idaho's topic in Minelab Manticore Forum

Does this mean that the 11 inch coil will go as deep as the 15 inch coil on my 800? 😁 -

When we find silver jewelry, you can use one of the several methods of cleaning it using aluminum foil. We wrap the item in the aluminum and then use baking soda, vinegar and hot water and it transfers the corrosion to the aluminum. Some pieces actually make a hole in the aluminum. Here is a video specifically for coins. There are many. I don't know if this enhances the value of the coins. How To Clean Tarnished Silver Coins Shine And Polish Silver Fast And Easy - Bing video

-

Condor's 2022 Australia Gold Adventure

mn90403 replied to Condor's topic in Detector Prospector Forum

Well Steve, another trip accomplished as Gerry says. I'm sure you wanted more weight. We all do. The one bright side I can see is that just in case you have to smuggle in your gold in a body cavity it won't be as painful as several more ounces! One of these days I'll see you in Yuma again. Mitchel -

Yuba, I share your skeptical view based on the lack of quality workmanship. Perhaps it is just a south of the border knockoff? It does not say .925. It only has a few stamps on it and the turquoise is rather inferior compared to the boldness of the ring. What do you call that type of 'cross?' Mitchel

-

Quality items have been a bit scarce lately but I did find this nice ring (and 4 others). It is 13 g with the markings as you see. It has a 22 and a BO or a B0. I don't know what they mean.

-

Ah ... you nugget eaters are all alike. Showing off your golden smiles. I hope that one didn't get dollied up and made into a poopy pour. Thanks for sharing the color.

-

Simon, You are probably right. This is also the reason why Minelab didn't respond to the 'issue' earlier as they didn't know what to fix and then they didn't have a way to fix it until you found it was complete. Costly error no doubt. An error of this magnitude at another detector company could very well put it out of business.

-

Norvic, You are a MOD man. We've seen what you did with the 2300! I'm sure you can make almost anything 'work' and put it to use just the way you get it. You adapt to the way your detectors work when you get them even if they are not working the way they were designed and advertised. I don't own a 6000 but I've seen here many of the shortcomings it has as well as its good finds. I do own an Equinox and it had to be replaced. The shafts were also replaced. Other people have had theirs leak and there are other known problems that Minelab has addressed under warranty. It's a good detector but just like the 6000 it was released with liability problems for Minelab. Some of these problems have caused detectorists real problems when they are on prospecting trips. They want what they pay for and not have to mod/adapt everything. They want a more finished product with fewer problems, but can this really happen with detectors? We'll have to start a new thread of what was the most reliable detector ever made. I'd say my 5000 is so adaptable/reliable that I don't know when it had a problem except for the ground tracking button on the handle.

-

I know because I had the Fisher coil but for those who have not seen the other 'system' for coil attachment they don't know how stress free it is on the coil ears. The Fisher system does not require that you pinch the coil ears together to keep the coil from moving. The Minelab design for many years has relied upon a pinch to work and when you pinch the ears tightly at the bottom with a big-headed bolt, this causes the ears to break away from the coil itself when just adding a little more tightness/torque over the weeks and months of use.

-

Well, the schedule didn't permit me or the tester to use the Axiom today, but he did say he was impressed so far. It has features he likes and will create its own niche in the detector marketplace. Taking him at his word it says a lot. I'm not disclosing an identity so he can have more control over his testing. I do have a picture I may post in a few months.

-

I held an Axiom today! A new tester/reviewer has one and he showed it to a few of us. It is very light and well balanced with a solid 'stick' sort of feel. I didn't get the sense of a coil heavy device. Reminds me of the Equinox with the 6" coil. It sounded great with the onboard speaker. I'm sure if they are not near a release date, he can provide a present evaluation to be considered. I'll see it again tomorrow and maybe use it.